Page 1 of 1

3d printed ammo testing

Posted: Wed Jun 06, 2018 11:57 pm

by Cthulhu

My school broke their old cheapo 3d printer and simply threw it away. But one man's trash is another man's treasure, and after getting my grubby hands on it I've replaced the nozzle and coded a plugin for cura to fix the printer's leveling issues. Now it can actually make some stuff!

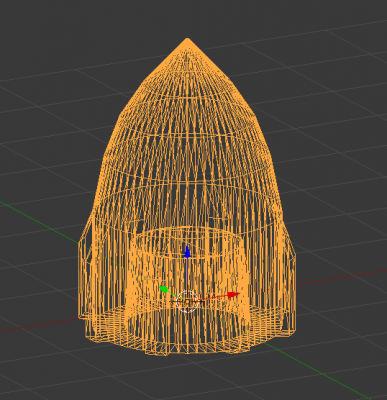

I designed the shot in blender and exported it to cura for slicing before printing.

- notice the hollow cavity at the base to make the projectile more top heavy

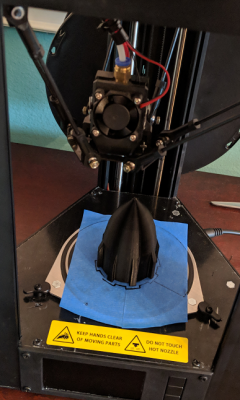

I decided to print with 25% infill so that the shot would be durable but not too expensive filament wise. This made it come out at 31 grams, which is pretty light, but a later version will have a hollow cavity to add some weights. The shot is 51.5mm in diameter so that it fits nicely in 2 inch schedule 40 PVC (some wadding wouldn't hurt though).

- You can see how much tinkering I have to do to get this thing to print right :P

Then I got carried away painting it. I know that the paint will just come off after a few shots, but I had nothing to do today anyways

- yeah I got carried away with the spray paint. The gold fins and tip kind of look like a drive band and a fuse which I thought was neat

Technically wise I know this isn't the ideal projectile. The fins are too small to have any real effect, and the squat shape doesn't make it the most stable projectile. But this was mostly just a test to see if it could be done, and tomorrow I will post shooting results.

3d printing projectiles doesn't seem very practical to me, as even this simple shape took over 4 hours to print and used quite a bit of filament (which can stack up in price). If anything, 3d printing projectiles is best for making molds to caste projectiles or possibly for complex sabots (if that's your thing). Nevertheless, printing projectiles is the best thing I've got right now since I have no lathe or mill to produce anything nicer (and by nicer I mean precisely shaped).

If anyone has any ideas for projectiles to print, I'm all ears!

Re: 3d printed ammo testing

Posted: Thu Jun 07, 2018 7:35 pm

by Cthulhu

I went to test the projectile today, and things seem to need some development.

I fired the shot at only 40 psi and at a 45 degree angle from a simple sprinkler valve mortar using a foam wad.

For one, I only got one shot before I lost it

For two, it was definitely too light, it didn't have as good range as I expected and I could see it being drastically pulled to the side by the wind.

For three, it tumbled as it fell from its apogee, showing that the design wasn't very stable (as I predicted).

Wish I could have gotten a video of it flying, but it literally bee-lined into a bunch of shrubbery about 300 feet away, and I wasn't about to go get bitten by a snake trying to find it

I'm going to redesign it with a longer body and wider fins, does anyone know if helical or canted fins are worth it? If so, what angle should I make them to spin stabilize the shot?

Re: 3d printed ammo testing

Posted: Fri Jun 08, 2018 7:14 am

by jrrdw

Nice effort with room for improvement like: Make it solid, 100% fill setting on the printer, or go a cheaper route and print a outer shell and fill with candle wax. Do away with angling the fins and just put a 45º chamfer on the leading edges, the forces to be will put enough rotation on it to help stabilize it.

Longer is better because you can trim down the length for the best performance as you go, once that drops off again you know how long to print the next one.

I would keep each developed projectile to it's own launcher because these rounds will preform differently from launcher to launcher. Get help watching where your rounds land and reuse as much as possible for a better control of repeatability.

Don't worry about sneaks, they don't like you either! L0L :bigsmurf:

Re: 3d printed ammo testing

Posted: Fri Jun 08, 2018 9:49 am

by wyz2285

If you're too lazy I saw

this not long ago, there are some pretty sweet looking rounds that you can print.

Re: 3d printed ammo testing

Posted: Mon Jun 11, 2018 3:47 pm

by Cthulhu

I'm taking a break from printing projectiles for my 2 inch bore cannon and I decided to experiment with some smaller 1/2" projectiles.

I designed this one to be somewhat like a foster slug, but I implanted a turned hardened steel spike into the tip to give it weight and allow it to stick into my targets.

- I printed this one in purple because I kept losing the black ones which were hard to find in the grass.

What's nice about these are that they fit in both my sprinkler valve airgun and in my blowgun, so the compatibility is nice. They weigh a little over 2 grams, so they're still very light, but I find that you can get away with that better with smaller bores.

I was very surprised by the accuracy of this foster slug, it flies much straighter than any of my homemade duct tape darts and a lot faster too!

Re: 3d printed ammo testing

Posted: Tue Jun 12, 2018 3:13 pm

by jakethebeast

I have had somewhat of a success with some 3D printed diabolo style slugs, haven't tested those in larger calibers though

Re: 3d printed ammo testing

Posted: Tue Jun 12, 2018 9:53 pm

by Cthulhu

jakethebeast wrote:I have had somewhat of a success with some 3D printed diabolo style slugs, haven't tested those in larger calibers though

yeah, I messed around with diabolos for the 1/2" bore awhile ago and I had great results with them. I found that even though they often weighed only a couple grams, that they could fly very straight and far without tumbling. Maybe some 2" diabolo tests need to be conducted :scratch:

- I found that the hollowpoint with a .12 gram airsoft BB glued inside the cavity flew the best.

Re: 3d printed ammo testing

Posted: Wed Jun 13, 2018 2:19 am

by jakethebeast

I'm testing weighted and unweighted diabolos at 42mm as soon as I have time to print them.

My previous test with diabolos were with 20mm caliber and a coaxial launcher running on unregged co2. Needles to say the PLA rounds flew pretty well but didnt survive on impact hehheh

Re: 3d printed ammo testing

Posted: Wed Jun 13, 2018 4:55 am

by jackssmirkingrevenge

Glad to see the crazy Finn is still at it

Re: 3d printed ammo testing

Posted: Wed Jun 13, 2018 10:04 pm

by Cthulhu

- The little steel spike should help with mass and penetration a bit.

Just printed this little stinger

I took the advice of the 45 degree chamfer on the leading edge of each fin (there are 8 total), and I'm excited to see how well they stabilize the little half inch projectile. I also made this one a lot longer than my previous projectiles (28.7mm tall with a 14.45mm diameter), primarily to increase stability but also because I wanted to increase the distance between the fins and the head of the projectile so that the wide head wouldn't deflect all the air going to the fins. I added a bit of a diabolo shape to help with the air deflection and to help weight balance. Finally, I epoxied a small steel spike inside the tip to add more weight and hopefully help the projectile penetrate into it's target a bit deeper.

I'll post an update on the performance tomorrow!

Re: 3d printed ammo testing

Posted: Thu Jun 14, 2018 10:53 am

by jackssmirkingrevenge

That looks like it will work pretty well, make sure you film it

Re: 3d printed ammo testing

Posted: Thu Jun 14, 2018 12:13 pm

by Cthulhu

jackssmirkingrevenge wrote:That looks like it will work pretty well, make sure you film it

If only I had a highspeed camera!

I'm going to set up a video with all these projectiles sometime this week and set them up against different tests such as range, penetration, and possibly velocity (if I can find someone with a chronograph

).

Re: 3d printed ammo testing

Posted: Fri Jun 15, 2018 3:52 am

by jrrdw

Yea I think with the new design that puppy is gonna hammer what it hits. I don't think it's going to last long, the spike is going to split it like cutting fire wood. Only one way to find out! :bom: Would like to see this in a wind tunnel type test with smoke trailing over it...

Technically wise I know this isn't the ideal projectile. The fins are too small to have any real effect, and the squat shape doesn't make it the most stable projectile. But this was mostly just a test to see if it could be done, and tomorrow I will post shooting results.

Technically wise I know this isn't the ideal projectile. The fins are too small to have any real effect, and the squat shape doesn't make it the most stable projectile. But this was mostly just a test to see if it could be done, and tomorrow I will post shooting results.