Launcher Failure Analysis Log

The idea behind this thread was taken directly from a sticky on the Spudtech forums, seen at http://www.spudfiles.com/spudtech_archi ... php?t=9835. I, along with several other members, believe that this topic would be a good idea for a sticky.

The purpose of this topic is to discuss launcher failures and why they happen, in hopes that the knowledge attained will help make future spudguns safer. Post as much information regarding your failed launcher as you can: type of spudgun, building materials used, pressure used, fuel used, probable cause of event, area of the launcher where failure occurred, temperature, and any other information which you believe will be useful. Other members will then comment on the failure, and hopefully conclusions will be drawn, which will allow everyone to learn how to avoid experiencing a similar failure.

From Moderation:

I would ask that all responses be well thought, and of a reasonable speculatory nature. Images would also be preferred.

The purpose of this topic is to discuss launcher failures and why they happen, in hopes that the knowledge attained will help make future spudguns safer. Post as much information regarding your failed launcher as you can: type of spudgun, building materials used, pressure used, fuel used, probable cause of event, area of the launcher where failure occurred, temperature, and any other information which you believe will be useful. Other members will then comment on the failure, and hopefully conclusions will be drawn, which will allow everyone to learn how to avoid experiencing a similar failure.

From Moderation:

I would ask that all responses be well thought, and of a reasonable speculatory nature. Images would also be preferred.

Last edited by Velocity on Sun Apr 15, 2007 12:23 pm, edited 3 times in total.

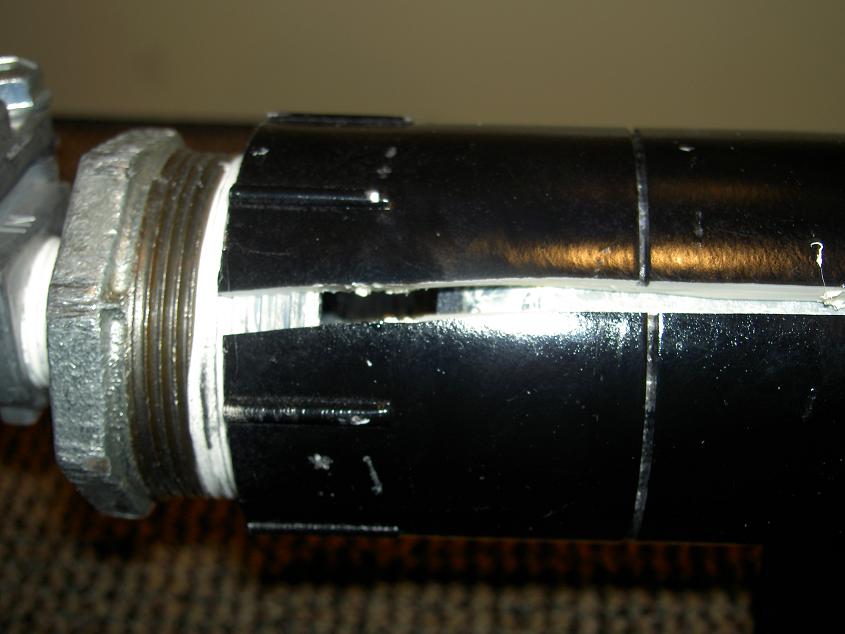

Launcher type: Piston-Valved Pneumatic, http://www.spudfiles.com/forums/viewtopic.php?t=4365

Temperature: About 53°F

Pressure used: Anywhere from 30 PSI to 50 PSI

Construction materials: All NSF-pw PVC fittings, SCH 40 steel bushing on the back of the piston valve

Area of failure: Female adapter of the piston valve.

Probable cause of failure: Bushing tightened too much, bumper was insufficient, piston was too massive

This cannon was loaded with a water-injected ping pong ball. My pressure gauge indicated that the cannon was filled to only 30 PSI, but that gauge is broken and usually reads a pressure which is below the actual pressure. The regulator on the compressor was set to 50 PSI, so it could not have been at a higher pressure than that. I fired the cannon, and a tremendous boom followed, louder than usual. This cannon is usually loud anyways, so I did not realize anything had happened. I noticed a white scratch on the valve, and upon closer inspection, I realize that the valve had cracked. Luckily for me, I had held the cannon by the chamber and barrel, and was not touching the valve at all. I was not injured at all by this incident.

More pictures:

Temperature: About 53°F

Pressure used: Anywhere from 30 PSI to 50 PSI

Construction materials: All NSF-pw PVC fittings, SCH 40 steel bushing on the back of the piston valve

Area of failure: Female adapter of the piston valve.

Probable cause of failure: Bushing tightened too much, bumper was insufficient, piston was too massive

This cannon was loaded with a water-injected ping pong ball. My pressure gauge indicated that the cannon was filled to only 30 PSI, but that gauge is broken and usually reads a pressure which is below the actual pressure. The regulator on the compressor was set to 50 PSI, so it could not have been at a higher pressure than that. I fired the cannon, and a tremendous boom followed, louder than usual. This cannon is usually loud anyways, so I did not realize anything had happened. I noticed a white scratch on the valve, and upon closer inspection, I realize that the valve had cracked. Luckily for me, I had held the cannon by the chamber and barrel, and was not touching the valve at all. I was not injured at all by this incident.

More pictures:

- VH_man

- Staff Sergeant 4

- Posts: 1827

- Joined: Sat Dec 09, 2006 6:00 pm

- Location: New Hampshire

- Been thanked: 1 time

YAY! this fourm is a good idea.

anyways like i said on the other fourm you proboably overtightened the bushing on the back. use plastic fittings to plastic fittings or dont screw your metal parts too tight and what happened to you wont happen to anyone else......... this happened to me once.....

anyways like i said on the other fourm you proboably overtightened the bushing on the back. use plastic fittings to plastic fittings or dont screw your metal parts too tight and what happened to you wont happen to anyone else......... this happened to me once.....

- LucyInTheSky

- Specialist 2

- Posts: 293

- Joined: Fri Apr 21, 2006 11:46 am

I have had two combustions fail on me because I used non pressure rated pipe. This stuff was only 3.2mm thick.

If your getting chased off a police dog, try not to run through a tunnel then onto a small see-saw then through a ring of fire. They are trained for that!

I don't have any pictures but I had a sprinkler valve fail badly.

What happened was I over tighted it on the inlet side and it cracked, and I did not notice it, and after a while and some shots, the body finally just gave way and crack apart. I was lucky tho and it did it at 30psi.

So what I would say is to not over tighten your valves, just enough and regular check the bodys and the threads for signs of cracking.

And great idea Mich.

What happened was I over tighted it on the inlet side and it cracked, and I did not notice it, and after a while and some shots, the body finally just gave way and crack apart. I was lucky tho and it did it at 30psi.

So what I would say is to not over tighten your valves, just enough and regular check the bodys and the threads for signs of cracking.

And great idea Mich.

- iPaintball

- Corporal 2

- Posts: 695

- Joined: Sun Mar 04, 2007 8:37 pm

I built a combustion with a 16" long 3" PVC chamber and a 4' long 1.5" barrel. I used mostly pressure rated parts, except two bell reducers that connected the barrel to the chamber. I forgot to prime the reducers, and being the amateur I was, I didn't think anything of it. When I fired it for the 3rd time, I used a rather tightly fitting potato. I fired it, and with a VERY loud report, the reducers shot off a good 10' from the cannon. It scared the hell out of me, and practically gave my mom a heart attack! Lesson learned: Use primer, especially when you are using DWV parts!

- homeflake210

- Private 3

- Posts: 50

- Joined: Mon Sep 25, 2006 6:33 pm

Heres a defective 2" PRESSURE RATED elbow. This thing blew up in my face and nearly hit me. The reason it failed is unknown but it might have been the fact that I was using a lighting fast opening 2" valve, a large chamber (4"x52"), it was at 115 psi, and the barrel wasn't attached.

My gb barrel failed when I was using chronograph just 3 days ago.

When I tried to load I noticed it was cracked. I was told it was designed with pnumatics in mind. I do not really mind I've got a source for sdr-21 now+ can build a new/different one.<img src="http://i116.photobucket.com/albums/o12/ ... G_0288.jpg" border="0"> In the video we made I can see the barrel flex a LOT.

I was going to paint with high temp. paint but never got to it.

Check it out flex is noticeable. http://tinypic.com/player.php?v=35ktq4n

When I tried to load I noticed it was cracked. I was told it was designed with pnumatics in mind. I do not really mind I've got a source for sdr-21 now+ can build a new/different one.<img src="http://i116.photobucket.com/albums/o12/ ... G_0288.jpg" border="0"> In the video we made I can see the barrel flex a LOT.

I was going to paint with high temp. paint but never got to it.

Check it out flex is noticeable. http://tinypic.com/player.php?v=35ktq4n

- paaiyan

- First Sergeant

- Posts: 2140

- Joined: Wed Dec 27, 2006 10:03 pm

- Location: Central Oklahoma

- Been thanked: 1 time

Perhaps the crack has something to do with the fact that the stuff is burnt to a crisp.sjog wrote:My gb barrel failed when I was using chronograph just 3 days ago.

When I tried to load I noticed it was cracked. I was told it was designed with pnumatics in mind. I do not really mind I've got a source for sdr-21 now+ can build a new/different one.<img src="http://i116.photobucket.com/albums/o12/ ... G_0288.jpg" border="0"> In the video we made I can see the barrel flex a LOT.

I was going to paint with high temp. paint but never got to it.

Check it out flex is noticeable. http://tinypic.com/player.php?v=35ktq4n

"Who ever said the pen was mightier than the sword, obviously, never encountered automatic weapons."

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

- schmanman

- Staff Sergeant 2

- Posts: 1685

- Joined: Sat Mar 25, 2006 12:28 pm

- Location: Michigan,U.S.A

- Contact:

ok, this was last fall....

I was shooting potatoes, apples, slugs, and pieces of pumpkins as buckshot. well, lets just say I crammed several pounds of pumpkin down the barrel, charged it up to 60 psi, then shot it. the gun was backed up against a railroad tie, so it couldn't move backwards. the recoil forced the barrel back, snapping the pvc in several places. luckily, i was able to remove the fittings that needed replacing, and the cracked pipe without damaging the valve, the two 4 inch elbows,or one entire air chamber. the tee under the tee with the valve in it, and the coupler, reducer, and pipe connecting it to the elbow all needed replacing.

the white parts are the ones I replaced (duh! )

)

I learned my lesson. I can now lift it up by the barrel. this keeps it from wiggling, so It will be more accurate, and it prevents this from happening again!

above is one of the old fittings.

I was shooting potatoes, apples, slugs, and pieces of pumpkins as buckshot. well, lets just say I crammed several pounds of pumpkin down the barrel, charged it up to 60 psi, then shot it. the gun was backed up against a railroad tie, so it couldn't move backwards. the recoil forced the barrel back, snapping the pvc in several places. luckily, i was able to remove the fittings that needed replacing, and the cracked pipe without damaging the valve, the two 4 inch elbows,or one entire air chamber. the tee under the tee with the valve in it, and the coupler, reducer, and pipe connecting it to the elbow all needed replacing.

the white parts are the ones I replaced (duh!

I learned my lesson. I can now lift it up by the barrel. this keeps it from wiggling, so It will be more accurate, and it prevents this from happening again!

above is one of the old fittings.

Persistence is a measure of faith in yourself

- Specialist

- Specialist 3

- Posts: 375

- Joined: Sun Mar 18, 2007 4:22 pm

- Location: Illinios

- Contact:

schmanman i thought that was your swat gun at first. well this thread has helped me a lot im knowing what to use and how to use it. i just wanted to thank you brave people for posting this to help people learn what can happen if you dont use gun correctly.  thank you!

thank you!

The flexing may have been the final force to cause it to snap but roasting plastic makes it brittle - just hold a bit of it over a flame until it looks like the edges on the hole there and test its flexibility to a non-toasted bit. The toasted bit will snap with much less plastic deformation first.paaiyan wrote:Perhaps the crack has something to do with the fact that the stuff is burnt to a crisp.sjog wrote:My gb barrel failed when I was using chronograph just 3 days ago.

When I tried to load I noticed it was cracked. I was told it was designed with pnumatics in mind. I do not really mind I've got a source for sdr-21 now+ can build a new/different one

The edges take the heat in a worse way than a large smooth surface like the inside of a pipe section and if they become brittle then a crack won't just stop there.

Honestly, I do not feel like the burning did too much to destroy your barrel sjog. I think the problem was that it was SDR-21. This thinwall pipe, though pressure rated to 200 PSI, is notorious for collapsing and such. There have been at least two incidents where the pipe has collapsed on itself in a coaxial setup, and numerous incidents where the pipe just snapped when being used as a barrel.

That cut you made to breech-load golf balls definitely had a role in causing it to crack, because it created a weaker space which was more prone to failure.

If you really feel that the burning of the barrel was a main factor, you could somehow get the breech part to seal better so the flame would only be contained to a small space. I would use a bored out 1.5" coupling, which fits 1.5" SDR-21 SLIGHTLY better than 2" SCH 80.

Oh, and Specialist, that is the SWAT gun.. just not the new version three... I assume that one of the reasons schmanman upgraded to the third version was because of these incidents.

That cut you made to breech-load golf balls definitely had a role in causing it to crack, because it created a weaker space which was more prone to failure.

If you really feel that the burning of the barrel was a main factor, you could somehow get the breech part to seal better so the flame would only be contained to a small space. I would use a bored out 1.5" coupling, which fits 1.5" SDR-21 SLIGHTLY better than 2" SCH 80.

Oh, and Specialist, that is the SWAT gun.. just not the new version three... I assume that one of the reasons schmanman upgraded to the third version was because of these incidents.

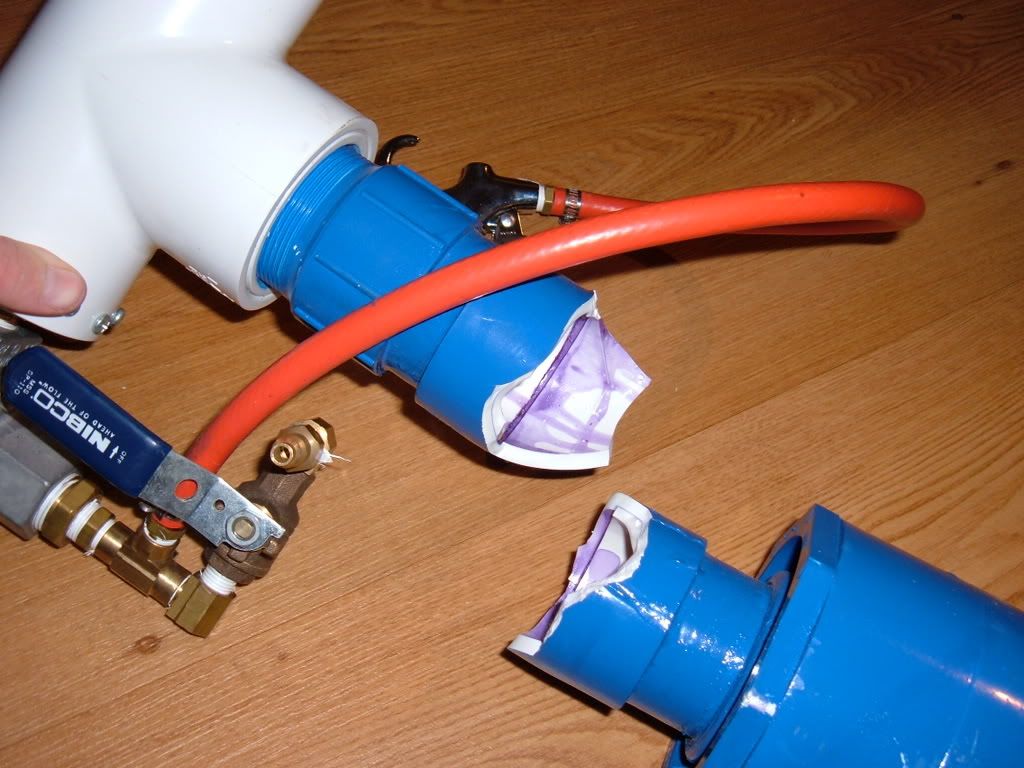

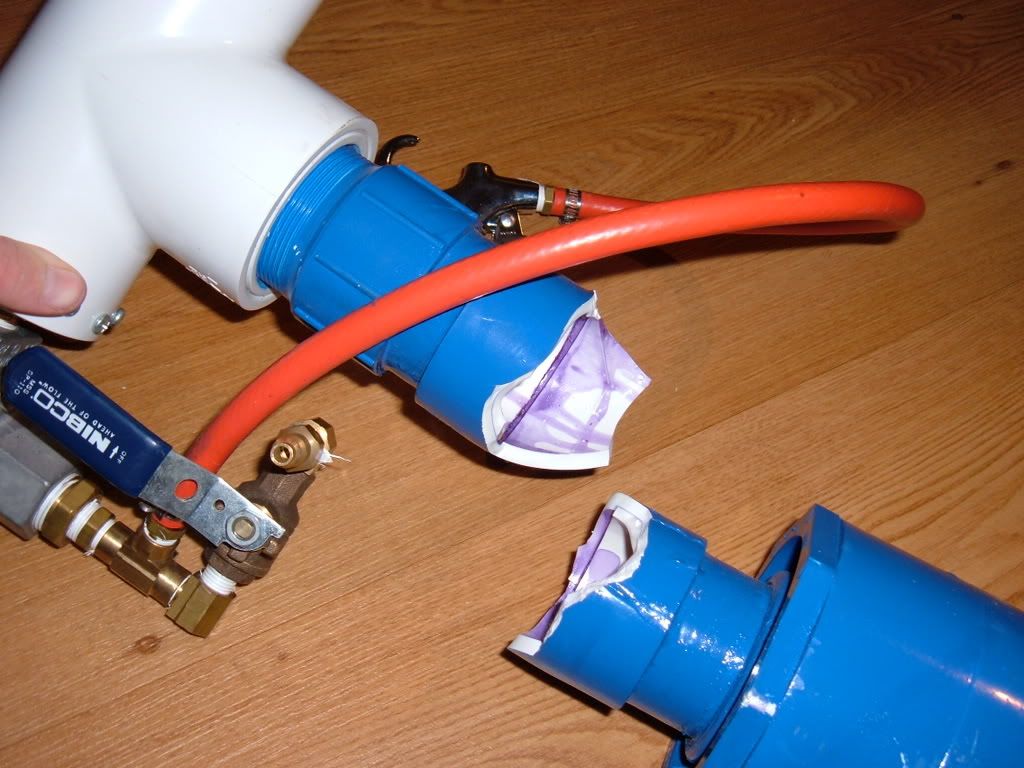

Launcher type: Piston-Valved Pneumatic, The Guillotine (10th post on page)

Temperature: About 57°F

Pressure used: 1st incident, 70 PSI

2nd incident, 50 PSI

Construction materials: Mostly NSF-dvw PVC fittings, SCH 40 NSF-dvw cleanout cap with pilot/fill system port in center (~1 in dia hole), all pipe NSF-pw

Area of failure: 1st incident, cleanout cap shattered

2nd incident, rear of valve removed due to brittle fracture

Probable cause of failure: DVW components, heavy (~2 lb) piston

The first failure occurred on the 1,800 ft shot referenced in the contest post, at which time the cleanout cap shattered, leaving only the threaded portions in place. The picture shows the reconstructed cap after we found all the parts.

<a href="http://s152.photobucket.com/albums/s161 ... CF1276.jpg">

<img border="0" src="http://i152.photobucket.com/albums/s161 ... 1177977235" width="256" height="192">

</a>

Click to enlarge

The second failure occurred once a new endcap and pilot was constructed (~24 hours), in similar weather, at 50 PSI. Projectile was a rock, ~1 pound (no more than the rockets we had previously fired). On firing, the piston exerted enough tensile stress on the rear of the wye to cause the rear portion of the wye to break. Brittle fracture occurred as a result of the short duration of the stress, and the rear of the wye, ~6in of 4 in Sch40 NSF-pw pipe, and the female adapter, cleanout, 2 solenoid valves etc, were removed from the rest of the valve at high speed, landing approximately 6 ft behind the gun.

<a href="http://s152.photobucket.com/albums/s161 ... CF1280.jpg">

<img border="0" src="http://i152.photobucket.com/albums/s161 ... 1178232812" width="256" height="192">

</a>

<a href="http://s152.photobucket.com/albums/s161 ... CF1281.jpg">

<img border="0" src="http://i152.photobucket.com/albums/s161 ... 1178232931" width="256" height="192">

</a>

Click to enlarge

In both cases, the failure was blamed on non-pressure rated components, but more importantly, the extremely heavy piston. A lighter piston is currently in the works.

-n00b

Temperature: About 57°F

Pressure used: 1st incident, 70 PSI

2nd incident, 50 PSI

Construction materials: Mostly NSF-dvw PVC fittings, SCH 40 NSF-dvw cleanout cap with pilot/fill system port in center (~1 in dia hole), all pipe NSF-pw

Area of failure: 1st incident, cleanout cap shattered

2nd incident, rear of valve removed due to brittle fracture

Probable cause of failure: DVW components, heavy (~2 lb) piston

The first failure occurred on the 1,800 ft shot referenced in the contest post, at which time the cleanout cap shattered, leaving only the threaded portions in place. The picture shows the reconstructed cap after we found all the parts.

<a href="http://s152.photobucket.com/albums/s161 ... CF1276.jpg">

<img border="0" src="http://i152.photobucket.com/albums/s161 ... 1177977235" width="256" height="192">

</a>

Click to enlarge

The second failure occurred once a new endcap and pilot was constructed (~24 hours), in similar weather, at 50 PSI. Projectile was a rock, ~1 pound (no more than the rockets we had previously fired). On firing, the piston exerted enough tensile stress on the rear of the wye to cause the rear portion of the wye to break. Brittle fracture occurred as a result of the short duration of the stress, and the rear of the wye, ~6in of 4 in Sch40 NSF-pw pipe, and the female adapter, cleanout, 2 solenoid valves etc, were removed from the rest of the valve at high speed, landing approximately 6 ft behind the gun.

<a href="http://s152.photobucket.com/albums/s161 ... CF1280.jpg">

<img border="0" src="http://i152.photobucket.com/albums/s161 ... 1178232812" width="256" height="192">

</a>

<a href="http://s152.photobucket.com/albums/s161 ... CF1281.jpg">

<img border="0" src="http://i152.photobucket.com/albums/s161 ... 1178232931" width="256" height="192">

</a>

Click to enlarge

In both cases, the failure was blamed on non-pressure rated components, but more importantly, the extremely heavy piston. A lighter piston is currently in the works.

-n00b

Launcher Type: Low mix hybrid cannon (3x propane and less)

Temperature: 82 degrees F

Mixture: 2x propane/ 2 atm

Construction materials: 2" Sch 80 PVC pipe and fittings

Area of Failure: Not too sure; all I saw was the back end of the cannon blow up. Pieces were blasted everywhere, and the smaller pieces were up to 50 feet away. There were dozens of small pieces which weren't found. In some places, the PVC was split on a double layer, which is more than 1/2" thick.

In my opinion, PVC hybrids are pretty much time bombs, just waiting to go off. This was about the 30th shot, and only at a 2x mixture, but apparently it was too much for the pipe. I will never make a PVC hybrid again, and I don't encourage anyone else to either. If you really want the massive power of a hybrid, spend a couple more (literally, not much more) bucks and make from steel, so you can go to extreme mixes without worrying about explosion of the cannon.

Temperature: 82 degrees F

Mixture: 2x propane/ 2 atm

Construction materials: 2" Sch 80 PVC pipe and fittings

Area of Failure: Not too sure; all I saw was the back end of the cannon blow up. Pieces were blasted everywhere, and the smaller pieces were up to 50 feet away. There were dozens of small pieces which weren't found. In some places, the PVC was split on a double layer, which is more than 1/2" thick.

In my opinion, PVC hybrids are pretty much time bombs, just waiting to go off. This was about the 30th shot, and only at a 2x mixture, but apparently it was too much for the pipe. I will never make a PVC hybrid again, and I don't encourage anyone else to either. If you really want the massive power of a hybrid, spend a couple more (literally, not much more) bucks and make from steel, so you can go to extreme mixes without worrying about explosion of the cannon.