Senior Project assistance - Automated pneumatic tennis ball

Wont need a sprinkler for that.

Just an electronic 5/2 valve and a cylinder which is returned by a spring.

Just an electronic 5/2 valve and a cylinder which is returned by a spring.

Update:

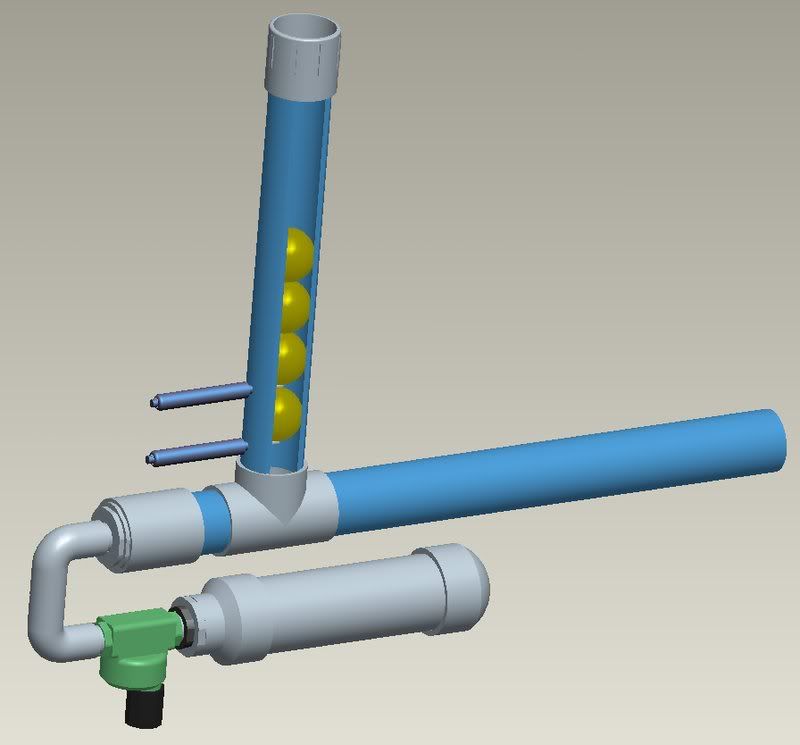

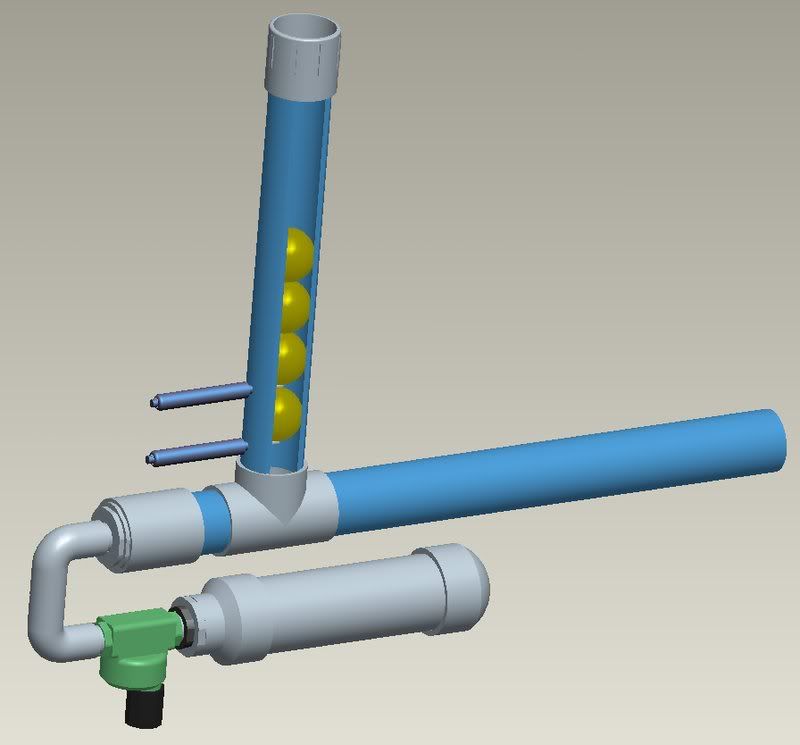

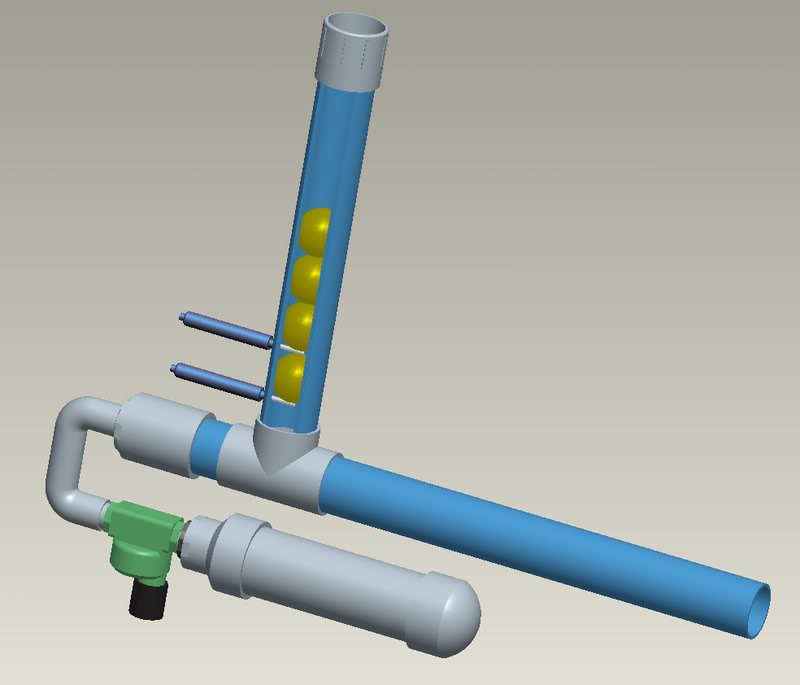

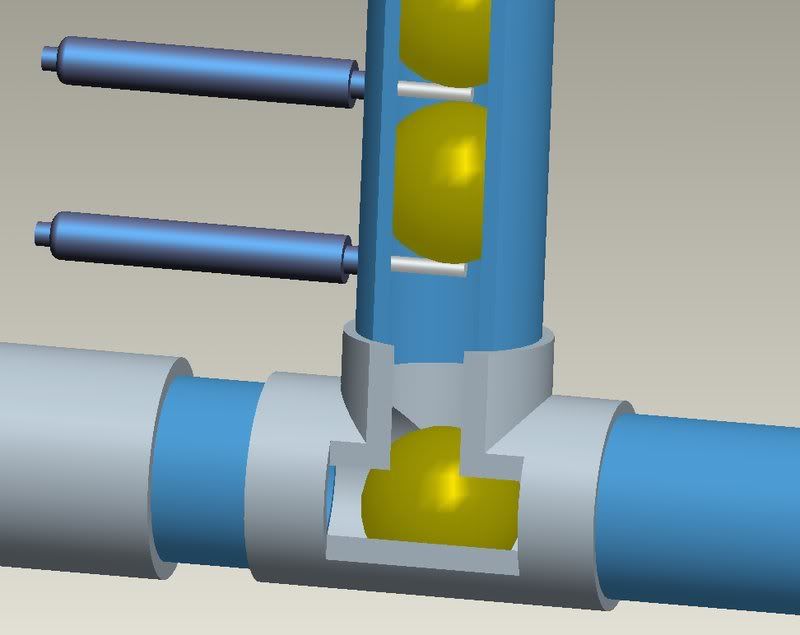

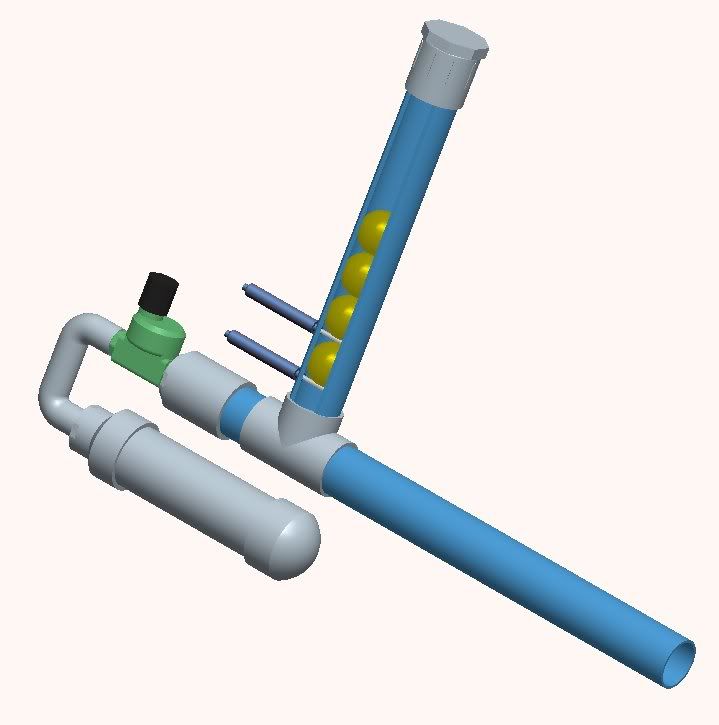

Sorry it's been so long everyone but end of semester is always chaotic. So I have some images here for your viewing pleasure.

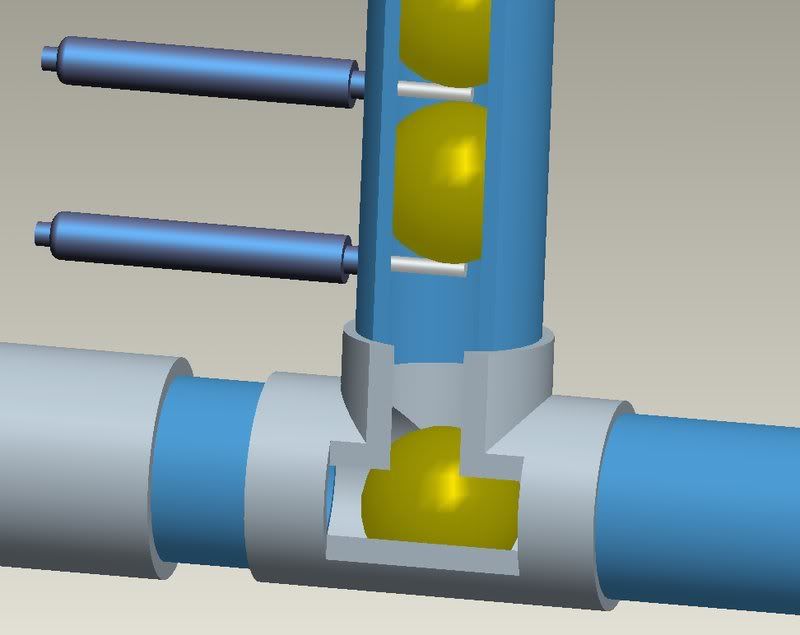

As you can see, we are planning to use a 2-stage actuator loading system. I think it's pretty self-explanatory. The only thing we may have to revisit is when the magazine is empty, all of the air will rush outwards (out the top of the magazine) because there will not be a ball that is sealing the breach. We are expected to use a screw on cap that has some type of fully extended gas shock and put a diaphragm on the end that extends downwards as the balls empty. [/img]

Sorry it's been so long everyone but end of semester is always chaotic. So I have some images here for your viewing pleasure.

As you can see, we are planning to use a 2-stage actuator loading system. I think it's pretty self-explanatory. The only thing we may have to revisit is when the magazine is empty, all of the air will rush outwards (out the top of the magazine) because there will not be a ball that is sealing the breach. We are expected to use a screw on cap that has some type of fully extended gas shock and put a diaphragm on the end that extends downwards as the balls empty. [/img]

Nice drawings and general design! The only thing you should consider is moving the sprinkler valve up directly behind the barrel instead of the air chamber. Dead space in the U...power killer...

This kind of magazine will probably leak like hell anyways, as you probably wont seal the pipe with spherical ammo. The balls will have to be pretty damn tight to stop those (8?) bar from slipping past.The only thing we may have to revisit is when the magazine is empty, all of the air will rush outwards (out the top of the magazine) because there will not be a ball that is sealing the breach. We are expected to use a screw on cap that has some type of fully extended gas shock and put a diaphragm on the end that extends downwards as the balls empty.

Do you really need the full length for the barrel or can you also live with a tiny bit shorter OR moving it up forward?

If so: move the sprinkler up in front of the U bend like starman said.

Less dead space where you will lose pressure and flow.

You could also pick a way inbetween: placing the valve between the 90 degree elbows.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 344 times

An air blown paddle would ensure single shot feed without bothering with the actuators, plus if your projectiles were a tight enough fit in the magazine air loss would be minimal.

Ditto on the valve position, it will pain you to anger the gods of efficiency...

Ditto on the valve position, it will pain you to anger the gods of efficiency...

hectmarr wrote:You have to make many weapons, because this field is long and short life

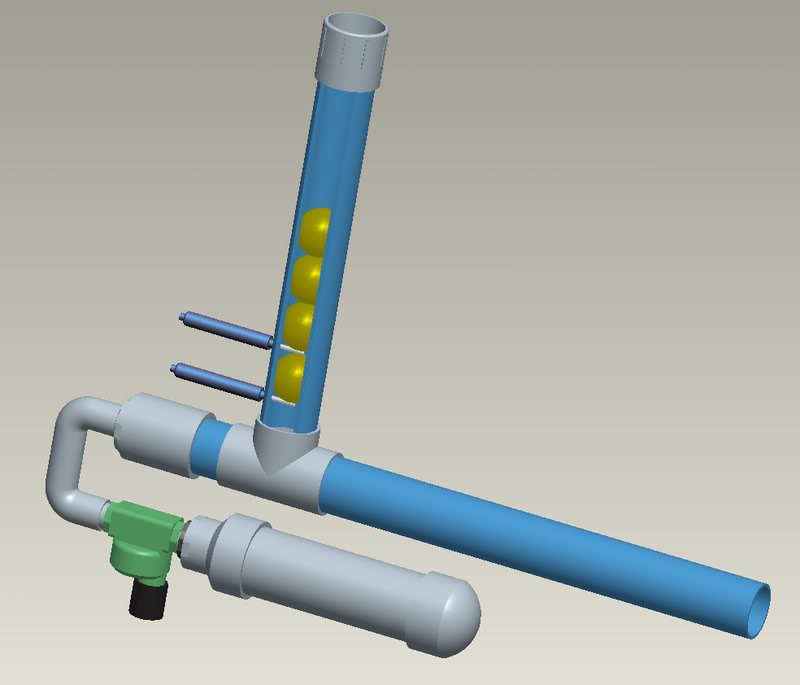

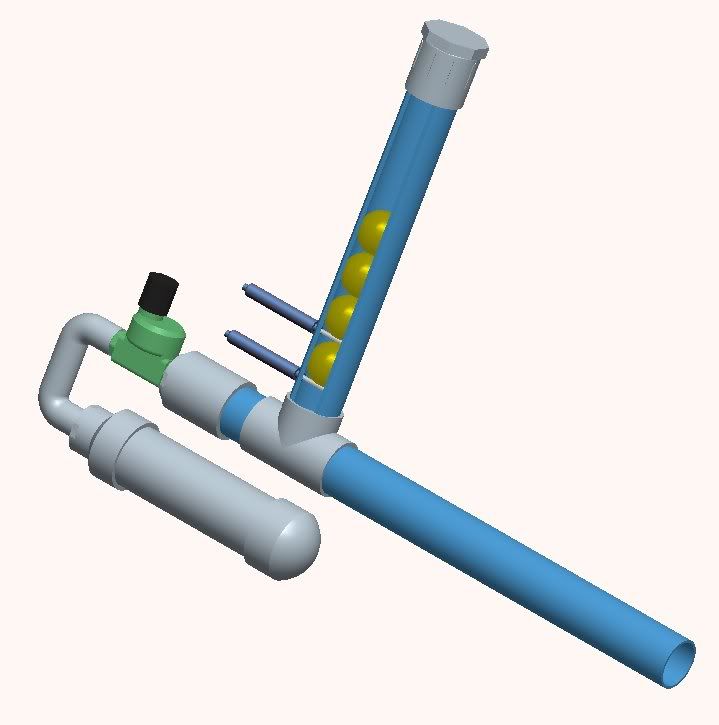

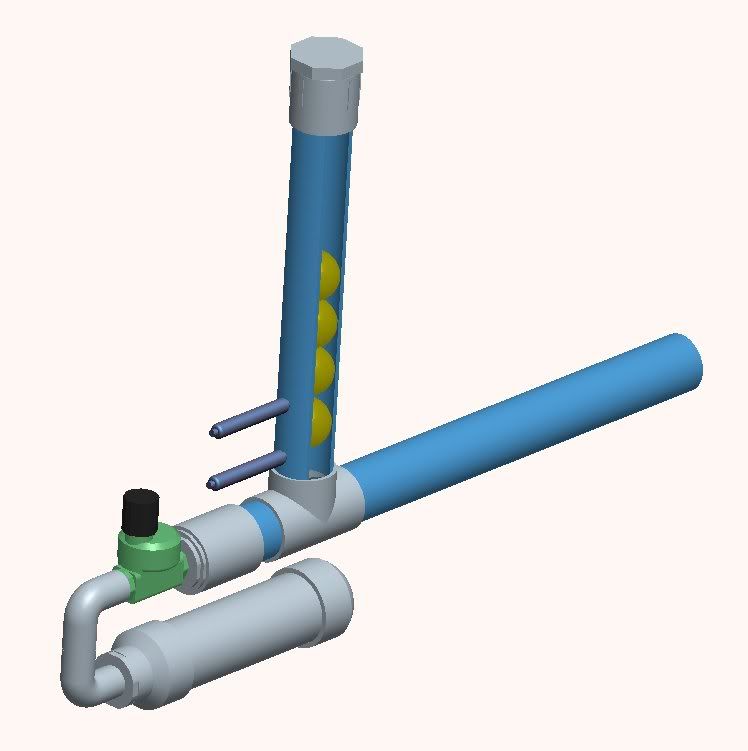

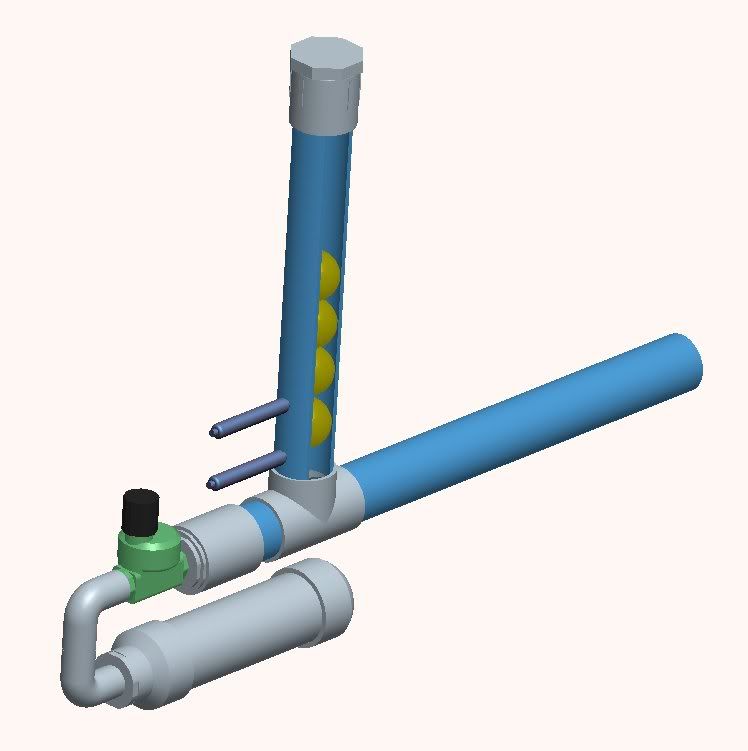

Hi guys, sorry for the absence. I'm sure most of you remember that a senior project is very involved. But I have made some progressions. I have all the parts but the 2.5" Tee, screw on cap, and coupling at the top of the hopper. Below are is updated version of the model, as you can see the valve is repositioned. I just got the 20oz CO2 tank in the mail today and will probably get it filled this week at some point.

After meeting with our adviser, we now have to incorporate target acquisition and recognition into the project. The plan is to use some type of pattern recognition to scan an area with a sensor (video camera? maybe?) then automatically aim the turret at the target and fire when in position. Problem is, I DONT KNOW ANYTHING ABOUT TARGET RECOGNITION! haha...

Does anyone have any suggestions on where to start?

After meeting with our adviser, we now have to incorporate target acquisition and recognition into the project. The plan is to use some type of pattern recognition to scan an area with a sensor (video camera? maybe?) then automatically aim the turret at the target and fire when in position. Problem is, I DONT KNOW ANYTHING ABOUT TARGET RECOGNITION! haha...

Does anyone have any suggestions on where to start?

- inonickname

- First Sergeant 4

- Posts: 2606

- Joined: Sun Dec 07, 2008 3:27 am

A light sensor is the easiest recognition system to start with.

It looks like you're doing fine with that design, but heres a few suggestions.

A solenoid valve actuated by a blowgun will be around 5 times quicker to open than a standard solenoid. This of course varies with the blowgun, valve etc. You could use a servo and a return spring to actuate the blowgun.

I don't know wether your spudgunning expertise is up to it, but take a look at this:

Clide's GB Semi

The initial valve is difficult to build, but you may want to implement a blow-forward breech as JSR suggested before. (The secondary valve on Clide's semi is a blowforward). These would also help fix your magazine problems.

Good luck.

It looks like you're doing fine with that design, but heres a few suggestions.

A solenoid valve actuated by a blowgun will be around 5 times quicker to open than a standard solenoid. This of course varies with the blowgun, valve etc. You could use a servo and a return spring to actuate the blowgun.

I don't know wether your spudgunning expertise is up to it, but take a look at this:

Clide's GB Semi

The initial valve is difficult to build, but you may want to implement a blow-forward breech as JSR suggested before. (The secondary valve on Clide's semi is a blowforward). These would also help fix your magazine problems.

Good luck.

PimpAssasinG wrote:no im strong but you are a fat gay mother sucker that gets raped by black man for fun

Thanks for the luck. One thing that's important to remember, if you look at my original post, is that this is only a very minor portion of my overall project. I know you guys love your cannons, but all I need is a simply designed cannon that will work repeatedly and consistently.

We have a few other topics like microprocessor programming, pattern recognition, servo controls, wireless video feeds, and remote control operation to cover, not to mention the entire fabrication of the robotic base.

I do appreciate the comments, I just don't need to build an extremely powerful and fast cannon.

By light sensor, do you mean like infrared?

We have a few other topics like microprocessor programming, pattern recognition, servo controls, wireless video feeds, and remote control operation to cover, not to mention the entire fabrication of the robotic base.

I do appreciate the comments, I just don't need to build an extremely powerful and fast cannon.

By light sensor, do you mean like infrared?

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 344 times

Wow, that's quite an added taskTeam PSU wrote:After meeting with our adviser, we now have to incorporate target acquisition and recognition into the project. The plan is to use some type of pattern recognition to scan an area with a sensor (video camera? maybe?) then automatically aim the turret at the target and fire when in position. Problem is, I DONT KNOW ANYTHING ABOUT TARGET RECOGNITION! haha...

Does anyone have any suggestions on where to start?

There are plenty of people who whave done it before though, take a look:

[youtube][/youtube]

If you look up "sentry guns" online you should get plenty of links to similar projects and perhaps people willing to offer advice.

- ALIHISGREAT

- Staff Sergeant 3

- Posts: 1778

- Joined: Sat Aug 25, 2007 6:47 pm

- Location: UK

That sentry gun is sick... imagine setting a few of those up to pin down a bunker on a PB field... the guys just wouldn't be able to move

<a href="http://www.bungie.net/stats/halo3/defau ... player=ALI H IS GREAT"><img src="http://www.bungie.net/card/halo3/ALI H IS GREAT.ashx"></a>

You'll want to tie the barrel and air tank together with a barrel support. There will be some shock loads on that U in the rear and sprinkler valve.

Roboman, we did run across the CMUcams. Turns out our lab already has 2 CMUcams, just not sure how to use them yet! haha. One concern is, this thing will be run outside in direct sunlight, I read that CMOS cams have a hard time dealing with it b/c it floods the red pixels and creates and ultra high contrast B/W image. Gotta look more into it.

Good news though, 80% of the fabrication is done as seen below. Very solid construction, a little heavier than anticipated though.

Can anyone give me some tips for plumbing in the brass fittings. I really dont want to mess it up now! I've got a schrader valve we're going to stick in the chamber as well as a hose barb for the C02.

Good news though, 80% of the fabrication is done as seen below. Very solid construction, a little heavier than anticipated though.

Can anyone give me some tips for plumbing in the brass fittings. I really dont want to mess it up now! I've got a schrader valve we're going to stick in the chamber as well as a hose barb for the C02.

- MaxuS the 2nd

- Corporal 2

- Posts: 674

- Joined: Sat Jan 19, 2008 3:59 pm

That bell reducer is pressure rated, right?

Badman

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 344 times

Assuming you'll be using pressures below 100 psi, tight hole and Araldite will suit you fineTeam PSU wrote:Can anyone give me some tips for plumbing in the brass fittings