FANG automatic Nerf gun

- john bunsenburner

- Sergeant 5

- Posts: 1446

- Joined: Sun Oct 19, 2008 5:13 am

You see thats why stupidity annoys me, but on the other hand we need people at mc donalds so it is ok(tough i am not a big fan of it, you get my point). We should put a little age limit/IQ range for people on here, would help sort out morons...

"Did you ever stop to think that out of the seven deadly sins envy is the only one which doesn't give the sinner even momentary pleasure"-George Will

Useless. People can lie about age, and installing a forum IQ test? It's usually clear who the idiots are, and they usually disappear after a few posts.john bunsenburner wrote:We should put a little age limit/IQ range for people on here, would help sort out morons...

I don't want to sound harsh, but you yourself are making a lot of unnecessary (and on occasions, somewhat stupid sounding) posts and comments, which makes it sound as though you're posting just for the sake of posting.

It's clear you're a person with some brains, but the posts you make don't always support that. Really, you need to calm your posting down.

You probably wouldn't believe it, but in spite of my post count, I type up a great many posts that I then discard for not being necessary or entirely coherent - I could post it, but I choose not to.

This "filter" helps counter <a href="http://en.wikipedia.org/wiki/Sturgeon's_law">Sturgeon's Law</a> (actually, his 2nd law, but it's seldom known as such) - by not submitting the posts which don't stand up to spec, overall, my posting is improved.

Anyway, my apologies for going off-topic.

Does that thing kinda look like a big cat to you?

- john bunsenburner

- Sergeant 5

- Posts: 1446

- Joined: Sun Oct 19, 2008 5:13 am

I guess i know that, that being the main reason i posted the above post. In the last few days i have felt very sick and was unable to do much else so i posted alot on here, to see what people think on different topics. I hope i will feel better in the next few days, allowing me to get back to my gun, to get some school work done and to finally finish(not just work on) my gun. Sorry if i annoyed people in the past few days, but i think my posting will improve/lessen in the next few days. So you all can be happy, you will most probably be rid of me alteast more of the time. Many people tell me i love to talk for the sake of doing so and i admit that i love to talk. Sorry if it got too annoying, but really there is nothing more to ask and i have eanoth knolage for atleast three or four guns now. I noticed i started pretty "far up" not using ball valves or premade valves at all and acctually making my own stock for the first gun of mine. Too late now, as mentioned before i will shut up for a while. And i guess this is counted as a useless post but i jsut wanted to tell you i realized what i was doing and that is was getting people annoyed. Sorry to all the people i annoyed

(getting really off topic, sorry)

(getting really off topic, sorry)

"Did you ever stop to think that out of the seven deadly sins envy is the only one which doesn't give the sinner even momentary pleasure"-George Will

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

I know exactly what you meant by "this is the most reasonable way to do it". I considered so many different setups before I settled on this one. It's by far the easiest to construct and probably the most reliable. You're not putting down anyone.btrettel wrote:I just realized my "it's less that great minds think alike" comment could come across wrong and I can't edit it now. I don't mean to put down anyone, just that an air cylinder pushing a bolt or breech is the most reasonable way to do semi-auto Nerf. So great minds do think alike.

How about "Great minds agree this is the most reasonable way to do it"?

It's a reliable solution that times itself naturally. It's not complicated, but the best solutions aren't - and the most reasonable way is often the most ingenious.

It's a reliable solution that times itself naturally. It's not complicated, but the best solutions aren't - and the most reasonable way is often the most ingenious.

Does that thing kinda look like a big cat to you?

magnificent, I worked my way on to spud gunning from nerf gun modifying nerf guns but I could never make something like this, how many darts can you fit in the magazine and how many can you shoot with a full chamber before having to repressurize?

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

@cheeseboy... I think he plans to use regged down CO2

I am sure you could build something like this if you really wanted to... that's basically one of the simplest design...

I am sure you could build something like this if you really wanted to... that's basically one of the simplest design...

Children are the future

unless we stop them now

unless we stop them now

There is very little dead space in the design as I said previously. I think I could possibly use a 3 inch stroke cylinder instead of the 4 inch one I am using right now, but that'd be cutting it close. It's definitely worth investigating.POLAND_SPUD wrote:I meant that the distance ammo has to cover while it is being fed from the magazine and pushed to the firing position makes you use an air cylinder that has the same stroke lenght as that distance...

consequently, any 'deadspace' there is makes you use a cylinder that is longer for that exact lenght... so acctually the overall lenght is increased by (2 * lenght of an unneccessary deadspace)...

if ammo has to go 4 cm through the tee this means that the cylinder has to have 4 cm longer stroke and this makes the gun (2 * 4 cm) = 8cm longer

I hadn't quite thought about the "extra" length from the longer air cylinder, but that's correct. Something to keep in mind for prototype 2...

On a similar note, I had considered putting the air cylinder on top and using a linkage of sorts to push the darts, but that was more complicated than I would have preferred. It's another idea worth considering (err... reconsidering).

The only major difference between different foam darts is the caliber, and making an effective weapon that can use different diameter projectiles would be difficult. Though, different weights are possibilities too, though I'd just choose whichever weight worked optimally at my typical operating pressure.john bunsenburner wrote:Ok something totally different to gun lengths:

You where talking about different kinds of fam darts, why not make 2 or 3 mags all with different darts, and you just use the best one for each situation, that would look pretty cool and maybe be really useful. It sounds like a powerful gun, i guess even foam darts can hurt so watch out, it would be a pitty if either some one took the gun away or if you hurt some one. Do some testing and show damage pics. Otherwise iahve to say once more great gun, good job...

p.s. I truely wonder what would happen if you used that thing on ply woad at maybe 250psi with lead slugs, if you decide to change your mind about using other kinds of ammo, and do what i just mentioned please get a camara first, we all would love to see the gun in action killing some ply woad...

The foam is necessary for a good seal, but I could make lead weighted foam darts and see how that works with the pressure cranked up... it should be spectacular.

Praise can't hurt, so keep it up.Ragnarok wrote:Looks great to me so far. Obviously, it still needs the finishing off and cleaning up, but that shouldn't press you unduly, having seen your previous water gun work.

Actually, I hadn't heard anything about your work in some time, but seeing this, it's still looking good.

Sorry, my posts in the showcase almost always end up being boring sounding praise, because I don't often have many questions to ask to spice up the posts.

I'll probably post some of my future water gun designs here too so watch out for them. I've been planning some interesting things with them lately.

That's it exactly.How about "Great minds agree this is the most reasonable way to do it"?

The current magazine will fit at least 10 darts.cheeseboy wrote:magnificent, I worked my way on to spud gunning from nerf gun modifying nerf guns but I could never make something like this, how many darts can you fit in the magazine and how many can you shoot with a full chamber before having to repressurize?

The plan is to make a higher capacity magazine eventually where I should be able to hold 20+ darts. That's on the drawing board... I choose a proved reliable method for the initial build.

POLAND_SPUD is correct. I have a paintball regulator I intend to use with either HPA or CO2. I have an HPA tank but have been considering using CO2 too. If I did use CO2 I'd change the PVC pressure chamber to metal, but aside from that I should be good.

I think I did the math earlier and my HPA tank could have had over 400 shots with a larger pressure chamber than what this build has. To increase the air use efficiency I intend to decrease the pressure chamber volume beyond it's currently small state too, but I'll need to make a model of this gun before deciding on that.

To summarize my current thoughts for changes for prototype 2:

- use a dual action air cylinder with an air spring to reduce the length, and potentially use a shorter stroke air cylinder

- put a sleeve of plastic around the barrel to prevent dents

- use less sizes of brass (It is not obvious but I have 4 different sizes of telescoping brass in this system... 3 would be possible but I didn't have the right size drill bit to allow for that.)

- potentially use a different directional control valve, possibly with higher flow

- consider a smaller QEV to reduce weight (the Cv values are all extraordinarily high for Nerf so it may not make a significant difference in performance)

- make model of this gun to minimize the pressure chamber volume and pressure for maximum range

- make a higher capacity magazine

- add retractable/adjustable/removable stock

- stain the handle and add grip tape (I might go for a prettier wood too)

- add trigger of sorts (I'm still considering various options)

For a trigger I'm considering various options. What I intend to do now is make some sort of linkage from the trigger area to the DCV. I also could use tubing to move the DCV closer to the trigger area, but that would increase the pilot volume and I'm afraid the DCV's flow might be too low to work optimally (though I doubt it because the additional volume would be so small). I also could use a different DCV I suppose. I'll need to do some more research into that.

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

sorry for mentioning overall lenght and stuff all the time but that's something important for me since I want to to get the highest possible power and that means I need as long barrel as possible...

I think you are on the right track.... you should use metal for chamber.. this would allow to use higher pressures so you can reduce the chamber volume at the same time...

I did some tests on double acting cylinders with one side used as an air spring and I think that this is 100% doable... I put 40 psi into the other side and it worked fine... however it retracted a little slow but that's mostly due to the fact that I used 2mm ID tubing and a valve with slow flow... at 70 psi it worked just fine...

I am still waiting for a 5 way valve to arrive... I plan to use the gun at 300 psi at least so it is a good idea to have a seperate regged down circut for an air cylinder...

I don't know if you have tested the cylinder at higher pressures but mine could easilly break fingers at 20 bar or crush marbles if something went wrong... that's something to keep in mind

Now one question about internals of the gun...

Is the volume between the tee and the air cylinder cut off from the rest of the gun when you fire ? if air can move there while you fire the gun this means that you lose a lot of efficiency

I think you are on the right track.... you should use metal for chamber.. this would allow to use higher pressures so you can reduce the chamber volume at the same time...

you might consider using steel or aluminium elements to make the gun a little bit more rigid... for example you could somehow sleeve the barrel into a malleable iron pipe (not all of it but even 10 - 15 cm would strenghten it a lot)put a sleeve of plastic around the barrel to prevent dents

this might help I just realised that single acting cylinders have to be longer because their body house a springuse a dual action air cylinder with an air spring to reduce the length, and potentially use a shorter stroke air cylinder

I did some tests on double acting cylinders with one side used as an air spring and I think that this is 100% doable... I put 40 psi into the other side and it worked fine... however it retracted a little slow but that's mostly due to the fact that I used 2mm ID tubing and a valve with slow flow... at 70 psi it worked just fine...

I am still waiting for a 5 way valve to arrive... I plan to use the gun at 300 psi at least so it is a good idea to have a seperate regged down circut for an air cylinder...

I don't know if you have tested the cylinder at higher pressures but mine could easilly break fingers at 20 bar or crush marbles if something went wrong... that's something to keep in mind

Now one question about internals of the gun...

Is the volume between the tee and the air cylinder cut off from the rest of the gun when you fire ? if air can move there while you fire the gun this means that you lose a lot of efficiency

Children are the future

unless we stop them now

unless we stop them now

It's fine to mention things you think could be improved. You got me thinking about something I hadn't considered, which is what I want.sorry for mentioning overall lenght and stuff all the time but that's something important for me since I want to to get the highest possible power and that means I need as long barrel as possible...

I think you are on the right track.... you should use metal for chamber.. this would allow to use higher pressures so you can reduce the chamber volume at the same time...

Yep, higher pressures are definitely something worth trying. I'm thinking I could get optimal performance with a tiny chamber at 200 or more PSI.

Of course, I don't know that for sure. Though I should be working on some other stuff I've already started making a mathematical model of the ballistics to help figure this out... assuming that a variation of the basic drag force equation applies here I shouldn't have too much difficulty figuring out the maximum range. Thankfully I remember a good deal about numerically solving differential equations...

Most metals are both too heavy and too expensive. Aluminum is light but still too expensive. Plastic is plenty rigid and cheap. Weight is something I'm very concerned about so plastic is plenty good for a simple barrel sleeve.you might consider using steel or aluminium elements to make the gun a little bit more rigid... for example you could somehow sleeve the barrel into a malleable iron pipe (not all of it but even 10 - 15 cm would strenghten it a lot)

Sounds good. Yeah, 2mm is kinda small so something larger might work better, or a better valve, or higher pressures.I did some tests on double acting cylinders with one side used as an air spring and I think that this is 100% doable... I put 40 psi into the other side and it worked fine... however it retracted a little slow but that's mostly due to the fact that I used 2mm ID tubing and a valve with slow flow... at 70 psi it worked just fine...

I am still waiting for a 5 way valve to arrive... I plan to use the gun at 300 psi at least so it is a good idea to have a seperate regged down circut for an air cylinder...

I don't know if you have tested the cylinder at higher pressures but mine could easilly break fingers at 20 bar or crush marbles if something went wrong... that's something to keep in mind

If higher pressures are optimal I'll use a smaller air cylinder to reduce the force it'll apply. Higher forces would probably shred the foam darts. Two advantages of higher pressures is that smaller air cylinders are cheaper and lighter.

The bolt seals very well against the tee. I hadn't explained much about the cycle or the seals but the telescoping brass tubes I've used are machined to high precision so they can slide over each other while sealing. I'm not sure they would seal at more than decent pressure but I figure the power lost for an intermittent pressure is negligibly small.Is the volume between the tee and the air cylinder cut off from the rest of the gun when you fire ? if air can move there while you fire the gun this means that you lose a lot of efficiency

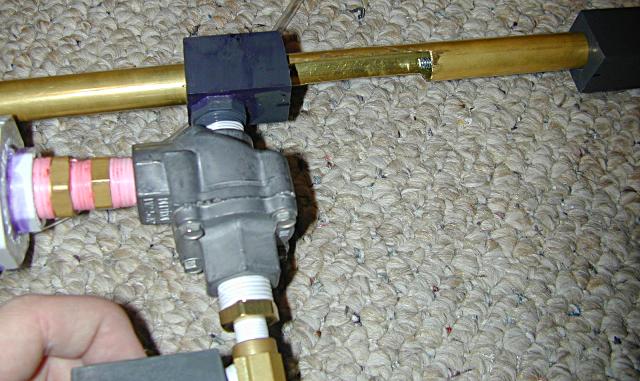

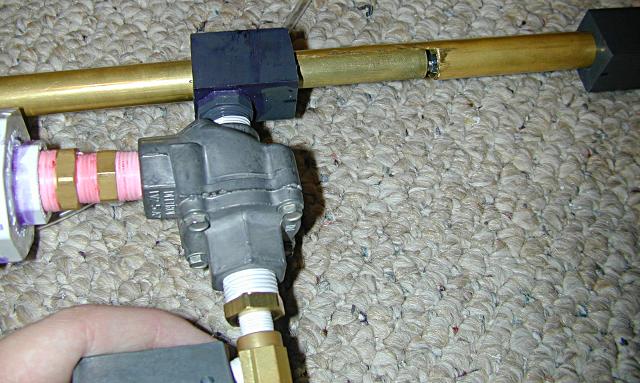

Here's some earlier photos of the bolt moving:

Some observations after using the FANG for a bit:

- Previously I had mentioned that the bolt has some issues returning. Originally I thought this might have been due to some dents in the telescoping brass tubes, but my tubes actually don't seem significantly worse than the new tubes I bought. Looking into other possible explanations I've concluded the air cylinder return spring is too weak. This essentially means I need to switch to a double acting air cylinder with an air spring.

- The fitting I made that attaches the barrel to the QEV leaks between the barrel and the fitting. I suppose this isn't surprising--the original plan was to epoxy the fitting to the barrel, but I never got around to it.

- Most of the jamming problems with darts had to do with part of the bolt I designed to push the dart but still allow flow through. That part was a screw and the darts could get caught on the threads. A smooth part would help.

- Because I didn't have a 9/16 inch drill bit I ended up using multiple telescoping tubes to get the OD of the tubes up to 5/8 inch. The tubes can slide around. This was a bad idea and I intend to correct it.

So far nothing I've seen seems impossible to fix. I still have a few weeks before I return to college so I'm going to try to fix these problems in the mean time. This likely will mean most of FANG will be reconstructed but if it'll make the gun more reliable, I'm all for it.

Edit: I'm going to have to apologize to the people who like the gun's current look because the changes I'm making to it will undoubtedly affect that. The appearance will be extremely similar, but the functionality will be greatly improved.

- Previously I had mentioned that the bolt has some issues returning. Originally I thought this might have been due to some dents in the telescoping brass tubes, but my tubes actually don't seem significantly worse than the new tubes I bought. Looking into other possible explanations I've concluded the air cylinder return spring is too weak. This essentially means I need to switch to a double acting air cylinder with an air spring.

- The fitting I made that attaches the barrel to the QEV leaks between the barrel and the fitting. I suppose this isn't surprising--the original plan was to epoxy the fitting to the barrel, but I never got around to it.

- Most of the jamming problems with darts had to do with part of the bolt I designed to push the dart but still allow flow through. That part was a screw and the darts could get caught on the threads. A smooth part would help.

- Because I didn't have a 9/16 inch drill bit I ended up using multiple telescoping tubes to get the OD of the tubes up to 5/8 inch. The tubes can slide around. This was a bad idea and I intend to correct it.

So far nothing I've seen seems impossible to fix. I still have a few weeks before I return to college so I'm going to try to fix these problems in the mean time. This likely will mean most of FANG will be reconstructed but if it'll make the gun more reliable, I'm all for it.

Edit: I'm going to have to apologize to the people who like the gun's current look because the changes I'm making to it will undoubtedly affect that. The appearance will be extremely similar, but the functionality will be greatly improved.

All spud gun related projects are currently on hold.

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

I use a double acting cylinder but I attached a normal spring to the front of it... (so it is pushed forward by the spring) I suppose you can replace a spring in yours (correct me if I am wrong)This essentially means I need to switch to a double acting air cylinder with an air spring.

but yeah... an air spring would work

Children are the future

unless we stop them now

unless we stop them now

I can't figure out a way to get my air cylinder open. I'll take a picture of it and maybe someone will have some suggestions. Good idea.

Either way, an air spring would work and be convenient because I could very easily change the force required to open/close the air cylinder.

Either way, an air spring would work and be convenient because I could very easily change the force required to open/close the air cylinder.

All spud gun related projects are currently on hold.

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

I could be wrong and I probably am, but I think that most cylinders are crimped and pretty much sealed for life.

- inonickname

- First Sergeant 4

- Posts: 2606

- Joined: Sun Dec 07, 2008 3:27 am

Awesome gun. The only real nerf stuff I've used is the tommy 20 thing (not nerf, but similar) and the mini footballs etc. Nerf wars aren't common round here, and airsoft is basically dead. Paintball and (lol) lasertag are the only things to survive..