Page 1 of 2

Ball valve trigger question

Posted: Tue Mar 04, 2008 5:27 am

by hotknife ralphie

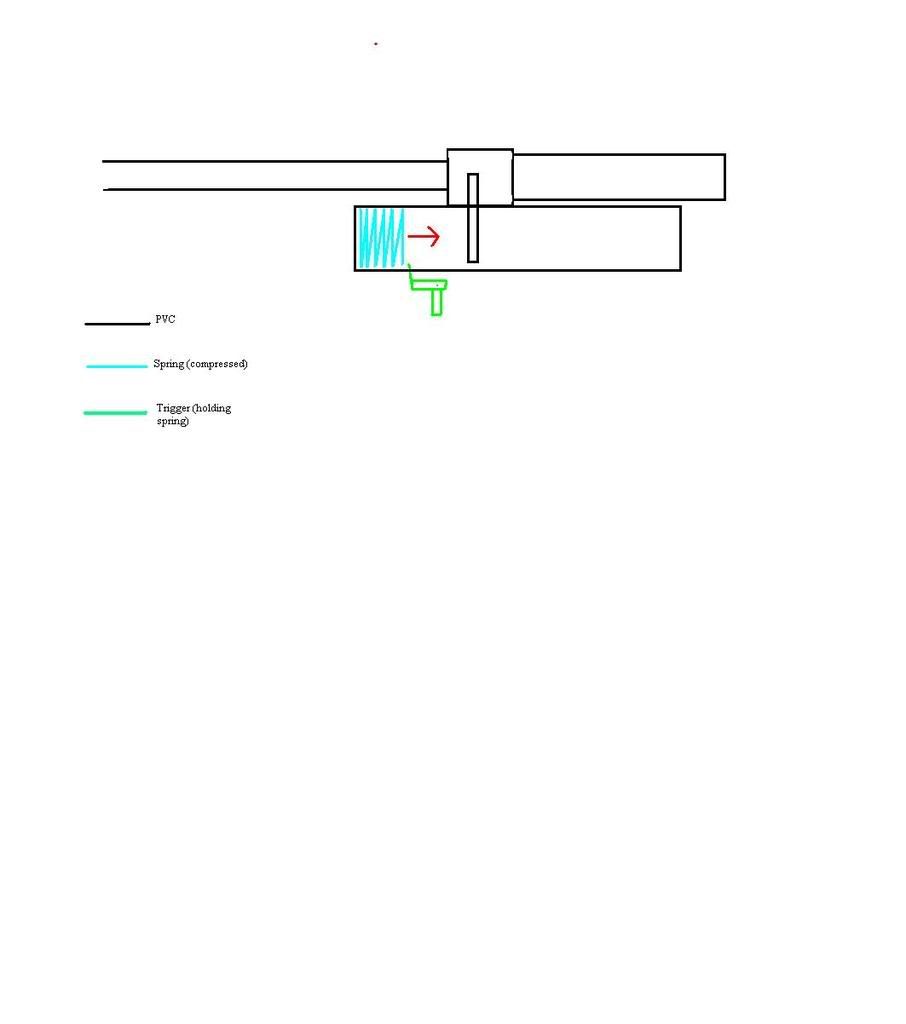

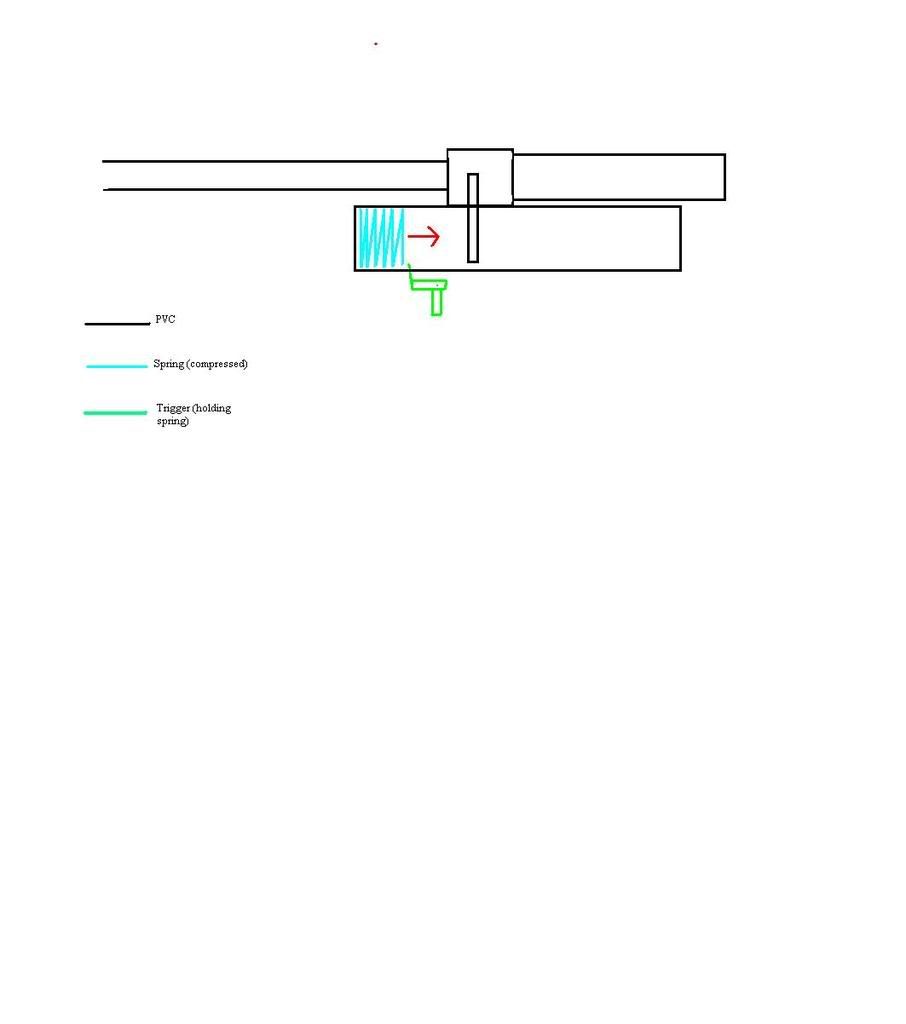

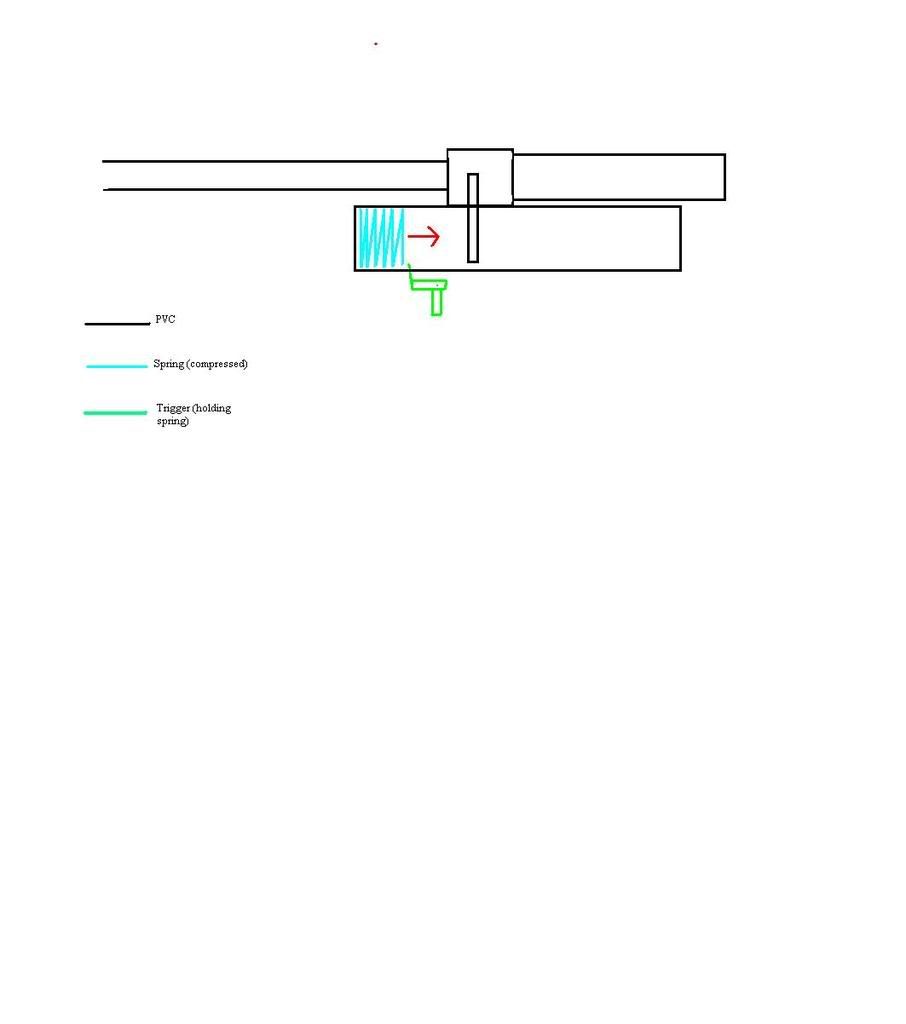

Evening, I was wondering if something like this would work?

I know that it would work far better if I were to use a sprinkler valve or a piston etc but atm I've made a ball valve gun out of spare parts and just want to pull the valve without the whole gun moving. Also I know springs can be used to trigger a ball valve eg

http://www.sentex.net/~mwandel/cannon/air_gun.html ,except the spring I have is different I can't remember what its called but they are found in those door open thingy's lots of people are using for springers eg

http://www.spudfiles.com/forums/spring- ... 13259.html

Thanks muchly.

Posted: Tue Mar 04, 2008 5:40 am

by Carlman

well according to your diagram if the valve did not move extremely easily than the valve would only open half way

Posted: Tue Mar 04, 2008 5:04 pm

by f.c

there are already a few string loaded pneumatic ball valve guns on here. but if where you i would just use a sprinkler valve, though pneumatically actuated ball valves aren't bad. you just need to create some type of pneumatic ram to turn the valve.

Posted: Tue Mar 04, 2008 8:00 pm

by DYI

As I've said before, if you could get a BV to open in less than 5ms, it would probably outperform a barrel sealing piston valve.

You're going to need either a mechanical or pneumatic spring driven ram with the proper hinging (which I really don't feel like drawing right now) to open the valve fast enough for decent performance. For barrel sealer/rupture disk type performance, you'll likely need a high explosive driven ram opening so fast that the ball valve would be destroyed by the kinetic energy of its own handle

Posted: Tue Mar 04, 2008 9:46 pm

by mega_swordman

It is an interesting idea, however, I think the main problem is simply getting enough force when ramming the ball valve. I believe it would be much more practical and effective if you pulled the ball valve with the spring that having the spring pushing it.

Posted: Tue Mar 04, 2008 11:26 pm

by Carlman

if you just have to have the spring push the handle you could have the spring housing in a 90* curve to follow the path of the valve handle but it still would not give the performance of a pulled valve

Posted: Tue Mar 04, 2008 11:40 pm

by jackssmirkingrevenge

DYI wrote:As I've said before, if you could get a BV to open in less than 5ms, it would probably outperform a barrel sealing piston valve.

In my opinion it is *much* easier to build an efficient piston valve (light, tight fitting piston, fast pilot valve and mimimum pilot volume) than to knock a ball valve open that quickly.

Posted: Wed Mar 05, 2008 12:26 am

by ghostman01

take a look at this it might just a bit and is a lot easier that what you are proposing

http://www.spudfiles.com/forums/ball-va ... 12985.html

Posted: Wed Mar 05, 2008 4:56 am

by hotknife ralphie

I realise that it won't be the picture of performance it was never meant to increase performance, it is a ball valve after all, the idea was purely for comfort reasons, 'cos trying to crank the ball valve open as quickly as possible is rather difficult while trying to aim and hold it in a way that it doesn't slip at hit me in the face. I've tried pistons before and I think I must be a 'pistard' (ohh the combination of piston and retard, simply hilarious...or maybe not) in the fact that I simply can't make one work. BUT!!! I did buy some more epoxy the other day and shall have another crack at one as soon as it all dries up. I may still try the spring idea, if it doesn't work no worries I'll just take it apart again. Thanks for the input guys.

Posted: Wed Mar 05, 2008 5:00 am

by ghostman01

no worrys mate i was searching for design many months ago and i came up with that one works for me !!! lol my gun with this trigger assembly puts out a big recoil youll be very surprised when you make one that really rips the bv open fast. have fun!!

Posted: Wed Mar 05, 2008 4:31 pm

by DYI

In my opinion it is *much* easier to build an efficient piston valve (light, tight fitting piston, fast pilot valve and mimimum pilot volume) than to knock a ball valve open that quickly.

That's the whole point, Jack. People think that they can avoid making a piston valve by just opening a BV faster, and I tell them just how fast it would have to open to rival a barrel sealer, and how achieving that would be 10x more expensive and complicated than just building a better valve.

Posted: Wed Mar 05, 2008 5:49 pm

by judgment_arms

Slightly off subject but, what is a reasonable opening time fire a spring loaded ball valve?

Posted: Wed Mar 05, 2008 6:39 pm

by clide

I donno DYI, I used to think the same way, but I've recently discovered that it is not terribly difficult to get what I would call a "good" opening time for a ball valve. Once I stop procrastinating maybe I'll elaborate on that more, but certainly it was an opening time that I would say is slightly slower than a typical piston valve, but I think the increased flow given by a BV would certainly put it in the same ballpark as a piston valve in overall performance.

Posted: Wed Mar 05, 2008 8:15 pm

by OuchProgramme

Step1. Create a stable stand for your cannon,

Step2. Attach yarn or some type of string to your ball valve.

Step3. Pull.

Posted: Wed Mar 05, 2008 8:18 pm

by bigbob12345

That is actually a very good idea and would increase opening time quite a bit if you pull hard.

ill have to try that, simple but effective