NO NO NO NO NO

, if you understand and have the craftsmanship to do it it than it is not to complicated, I'm sorry about resurrecting this topic, but I knew keepitreal, I talked with him in the topics where me and others explained to him many of the basic setup of pneumatic semis, and in the topic were he talked about the rotary cam,

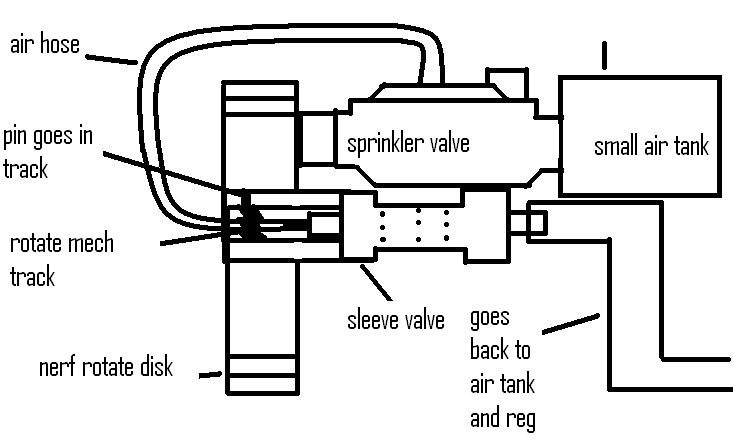

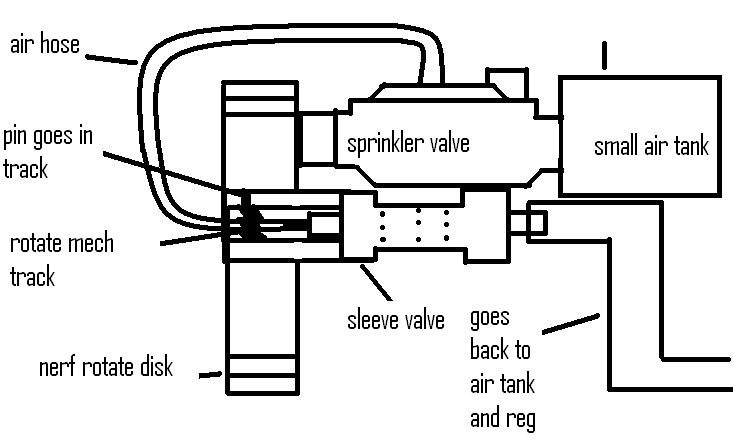

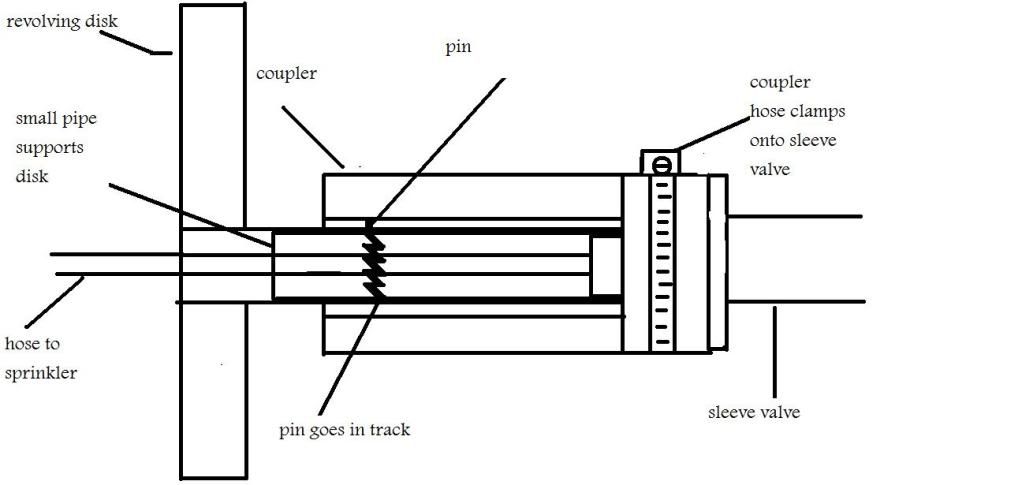

it seams to me that none of you have a dam clue about how a rotary cam works, it's pretty simple, it easier than making a true reliable working revolver based mechanism, keepitreal's creation was suppose to prove to the spudgun community that it is in fact practical to build your own rotary cam.

colty-bear, your design is fine assuming you just sketched a plain zig zag out of laziness and your intended design for the cam grooves looks more like keepitreal's then yes you shold know what your doing and you should ignore these people.

draw out your intended cam design on the pipe very carefully before you cut, send me a message next time you need help and these guys aren't giving you much, I'm not that active anymore but your private message should send me an email alert,and if for some reason I don't respond within 10 days feel free to send me another