8ft Coaxial Shoulder Launched Golfball Cannon.

Posted: Wed Mar 24, 2010 4:13 pm

So I've been on this site for a long time now, but I was mainly a lurker as I never felt I had much of a cannon worth posting, so I'll make this both my introductory post, as well as a post about my newest gun.

A little of my previous Spudgun history. I've always been into Pneumatics. I just like them a lot, so thats all I've ever made. I might make a hybrid next, who knows.

But anyway, my first cannon was a steel pipe and PVC cannon, with a half inch ball valve and a shrader valve to fill the thing. I made this when I was about 12, before I even knew this website existed, or before I had ever seen plans for such a device anywhere. It was more a 12 year old being curious and wanting to experiment, so I built that thing. It would shoot markers (the kind you write with) around 100 yards, and marbles clean out of sight. (never found any of them again to verify distances) It leaked like crazy, and was generally a mess, but I learned a lot from it.

The next cannon I built was basically a bigger version of the first. All threaded steel pipe tank construction, with a metal shrader valve, a 1 1/2 inch ball valve, and a 1.5 inch sch. 40 barrel for potatoes. I used JB weld in the metal pipe threads to permanently seal it up, and from day one it never leaked even a bit. Put 100psi in it one night, and the next morning you'll still have 100PSI in it. It was a lot of fun, and would still launch stuff pretty unreal distances due to the high pressures I could take it too, as well as learning to open up that ball valve as quickly as possible (i would stand up and kick it upen with my foot.) Ice slugs and frozen water balloons were lots of fun to shoot!

This is the cannon as of today, with two barrels. One is the 5ft 1.5" Sch. 40 Barrel, and the other is a 7ft 1.5" SDR 21 GolfBall Barrel.

Then when I was 15, I moved to Northern Ireland, where spudguns and such are generally frowned upon, which is understandable considering the sensitivity of that area to guns, bombs, and other such weapons. So my spudgunning stopped for 3 years, but in that time I was planning. Yea, you should never let me contemplate such devices for so long! By the time I moved back to America about 9 months ago, I knew exactly what I wanted to build the moment I hit US soil!

I wanted something BIG, I wanted it to be fired from the Hand or the Shoulder, and I wanted it to shoot golfballs since they're pretty cheap and designed for flight! I also wanted a piston cannon since that's pretty much the gold standard of reliable, powerful, and easy to use, pneumatic valveage!

So a few weeks of drawing, sketching, and thought later, I had in mind exactly what I wanted to make.

The specs are this:

-7ft SDR 21 golfball barrel sleeved in 2" Sch. 80 for strength (its only sleeved inside the cannon)

-6ft air tank, made of 4" pressure rated PVC

-The whole cannon is right at 8ft long when assembled.

-Plywood and foam piston, with a rubber sealing face. (foam keeps the piston lightweight)

-1/2 thick open cell foam, cut into a circle and glued to the back of the cannon as a piston bumper. Very effective, you hardly hear the piston hit at all!

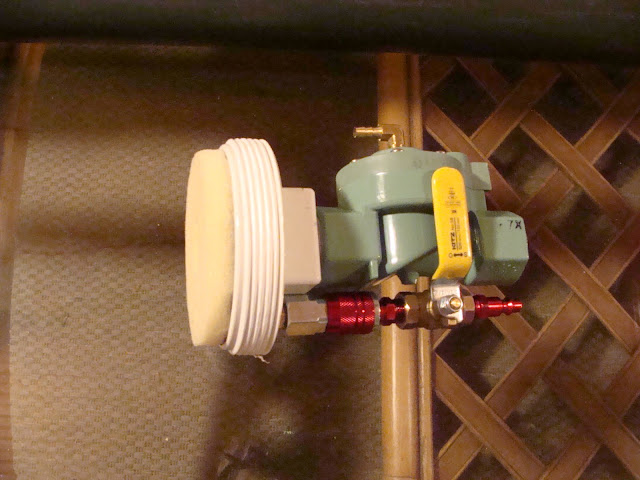

-Modified 1" sprinkler valve for quick and easy actuation of the piston. The sprinkler valve is modified for pneumatic actuation, and i've also removed the spring, which causes it to open faster, and for a slightly longer period of time.

-Quick disconnect with 1/4" ball valve for filling the cannon directly from an air compressor.

-125 PSI pop off valve to prevent over pressurization of the components for safety.

-Pressure gauge for accurately determining pressure.

I originally wanted to hold off on revealing the cannon until I was completely finished with it, i.e. paint, stock, and possibly a scope for accuracy, however I decided to just go ahead and show it in its unfinished, but operational state.

So with that behind, here are some pictures:

This is a picture of all the parts laid out before final assembly

The Piston, Barrel, and Tank before assembly.

Same as above, plus the blowgun trigger, and sprinkler valve trigger/ fill valve assembly.

Tank, and barrel, with the SDR21 protruding from the 2" Sch 80 it is sleeved in.

Valve assembly with foam bumper.

Blow gun trigger.

This is the Piston. Its very light for its size due to the foam used.

I cut the plywood and foam out using a dremel circle cutter attachment. The gasket I cut out by hand, and then sanded the edge smooth so that it sealed perfectly inside the gun.

A small bolt holds the whole thing together.

So you'd like video? 8)

[youtube][/youtube]

That shot was at 50 PSI. The gun will work at very low pressure, below 10PSI in fact. The piston moved so nicely in the 4" PVC, that with the sprinkler valve unscrewed from the back of the cannon, I could blow the piston forward and then suck it back with my mouth. It will easily put a golfball through plywood at 20PSI from about 25 yards (same place as the shot in the video)

According to GGDT, at 125PSI, this gun should launch a golfball around 610 ft/s.

Anyway, questions, comments and suggestions are all appreciated!

A little of my previous Spudgun history. I've always been into Pneumatics. I just like them a lot, so thats all I've ever made. I might make a hybrid next, who knows.

But anyway, my first cannon was a steel pipe and PVC cannon, with a half inch ball valve and a shrader valve to fill the thing. I made this when I was about 12, before I even knew this website existed, or before I had ever seen plans for such a device anywhere. It was more a 12 year old being curious and wanting to experiment, so I built that thing. It would shoot markers (the kind you write with) around 100 yards, and marbles clean out of sight. (never found any of them again to verify distances) It leaked like crazy, and was generally a mess, but I learned a lot from it.

The next cannon I built was basically a bigger version of the first. All threaded steel pipe tank construction, with a metal shrader valve, a 1 1/2 inch ball valve, and a 1.5 inch sch. 40 barrel for potatoes. I used JB weld in the metal pipe threads to permanently seal it up, and from day one it never leaked even a bit. Put 100psi in it one night, and the next morning you'll still have 100PSI in it. It was a lot of fun, and would still launch stuff pretty unreal distances due to the high pressures I could take it too, as well as learning to open up that ball valve as quickly as possible (i would stand up and kick it upen with my foot.) Ice slugs and frozen water balloons were lots of fun to shoot!

This is the cannon as of today, with two barrels. One is the 5ft 1.5" Sch. 40 Barrel, and the other is a 7ft 1.5" SDR 21 GolfBall Barrel.

Then when I was 15, I moved to Northern Ireland, where spudguns and such are generally frowned upon, which is understandable considering the sensitivity of that area to guns, bombs, and other such weapons. So my spudgunning stopped for 3 years, but in that time I was planning. Yea, you should never let me contemplate such devices for so long! By the time I moved back to America about 9 months ago, I knew exactly what I wanted to build the moment I hit US soil!

I wanted something BIG, I wanted it to be fired from the Hand or the Shoulder, and I wanted it to shoot golfballs since they're pretty cheap and designed for flight! I also wanted a piston cannon since that's pretty much the gold standard of reliable, powerful, and easy to use, pneumatic valveage!

So a few weeks of drawing, sketching, and thought later, I had in mind exactly what I wanted to make.

The specs are this:

-7ft SDR 21 golfball barrel sleeved in 2" Sch. 80 for strength (its only sleeved inside the cannon)

-6ft air tank, made of 4" pressure rated PVC

-The whole cannon is right at 8ft long when assembled.

-Plywood and foam piston, with a rubber sealing face. (foam keeps the piston lightweight)

-1/2 thick open cell foam, cut into a circle and glued to the back of the cannon as a piston bumper. Very effective, you hardly hear the piston hit at all!

-Modified 1" sprinkler valve for quick and easy actuation of the piston. The sprinkler valve is modified for pneumatic actuation, and i've also removed the spring, which causes it to open faster, and for a slightly longer period of time.

-Quick disconnect with 1/4" ball valve for filling the cannon directly from an air compressor.

-125 PSI pop off valve to prevent over pressurization of the components for safety.

-Pressure gauge for accurately determining pressure.

I originally wanted to hold off on revealing the cannon until I was completely finished with it, i.e. paint, stock, and possibly a scope for accuracy, however I decided to just go ahead and show it in its unfinished, but operational state.

So with that behind, here are some pictures:

This is a picture of all the parts laid out before final assembly

The Piston, Barrel, and Tank before assembly.

Same as above, plus the blowgun trigger, and sprinkler valve trigger/ fill valve assembly.

Tank, and barrel, with the SDR21 protruding from the 2" Sch 80 it is sleeved in.

Valve assembly with foam bumper.

Blow gun trigger.

This is the Piston. Its very light for its size due to the foam used.

I cut the plywood and foam out using a dremel circle cutter attachment. The gasket I cut out by hand, and then sanded the edge smooth so that it sealed perfectly inside the gun.

A small bolt holds the whole thing together.

So you'd like video? 8)

[youtube][/youtube]

That shot was at 50 PSI. The gun will work at very low pressure, below 10PSI in fact. The piston moved so nicely in the 4" PVC, that with the sprinkler valve unscrewed from the back of the cannon, I could blow the piston forward and then suck it back with my mouth. It will easily put a golfball through plywood at 20PSI from about 25 yards (same place as the shot in the video)

According to GGDT, at 125PSI, this gun should launch a golfball around 610 ft/s.

Anyway, questions, comments and suggestions are all appreciated!