3-WAY VALVES for charging/firing 2" piston cannons.

Posted: Mon Jun 28, 2010 4:55 am

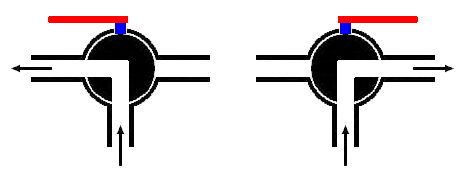

Notice the Mauler cannon has a 3-way valve as the trigger, when you fire the cannon, the airflow from the compressor is temporarily cut off while the pilot is vented.

Looks like that. with the QEV on the bottom, the compressor on the left and an opening on the right.

This is the spudtech.com valve that is called a "3-way valve", but does it allow charging and firing as I explained?

That's another valve I found, Will it allow me to do what I want, I think it's over 4" long, way too big for the 1.5" pvc handle of my cannon.

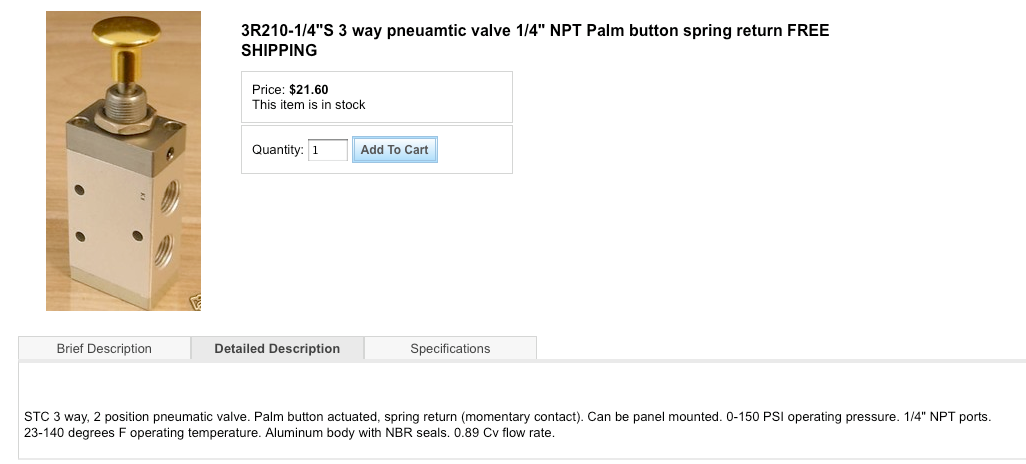

This one is possibly a little shorter...

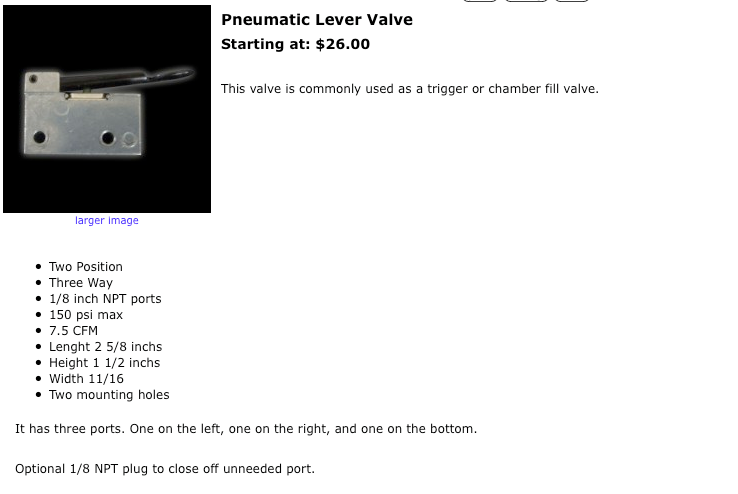

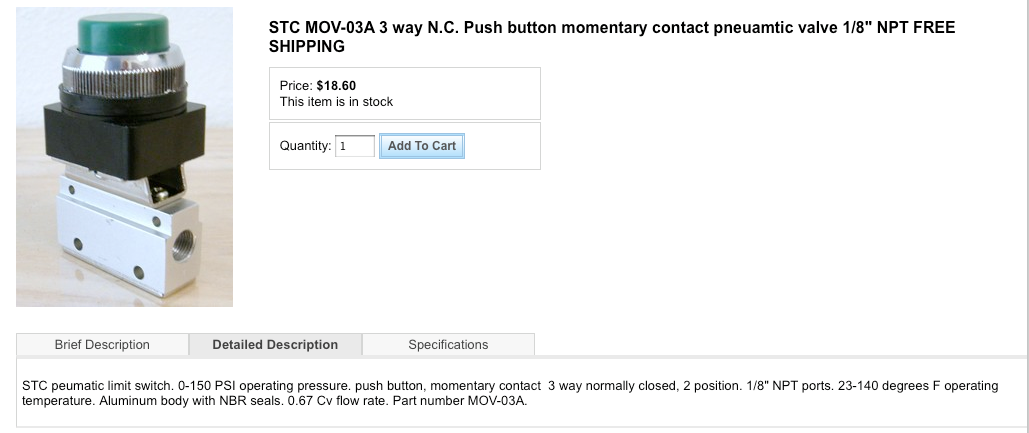

This one is shorter still but the 1/8" ports may be too small for filling a >430cu-in tank quickly and firing a QEV on a mauler valve...

LOOK, see how these either say "normally closed" or "normally open" WHHAAAT? This is confusing because in position "A" air flows from "X" to "Z" and in position "B" air flows from "X" to "Y", both positions could be called open AND closed. UNLESS THE VALVE DOESN'T DO WHAT IT I'M ASSUMING IT DOES, as shown in the above diagram.

OK, see this one too? It uses a solenoid. I could fire my cannon electronically if this were too work, but does anyone know if that flow factor which says "0.89" is suitable for what I need? That flow factor is probably completely inaccurate because I've seen the same value on all the other completely different valves on this site, I think the value was just pasted in for all the valves...

I want to do that, only bigger and portable and with my 20lb CO2 tank and reg.

That cannon pictured above from spudtech.com, has a C/B of 1.7, the spudwiki says that that GGDT shows the ideal ratios are around 0.2 and 0.3. Is that true? that seems ridiculous to have an air chamber 1/8th the volume of your barrel when using 125psi! I can't download GGDT on my crapple.

Spudtech's "theory" page says ideal ratios are between 2.0 and 4.0!

I thought I'd sketch a little bit of what I'm planning to give you an idea. Maybe it's goofy, but it was easier than using MS paint, notice the 3" pvc extensions on the piston valve, they are to allow the cannon to rest on the operator's shoulder. The fill line coming out the back connects to a 20lb co2 tank strapped to the operator's back. The loading mechanism is a 2" ball valve with an SDR-21 insert which feeds golf balls from a spring-loaded clip.

Tell me what you think.

Thanks.