I post here to present quickly my pneumatic cannons, and show you a new QDV design.

My first cannon, with a jack for the compressed air, and a simple QEV system no optimized at all. There is an hammer valve to strigger the shoot. I can shoot at différent caliber 6mm, 8, 12, 13.5 and soon 16mm for marbles. The service pressure is between 10 and 12bar (about 15psi)

The qev system will be replaced by the QDV that i'll speak about later.

Video :

[youtube][/youtube]

This winter, i'm builting a new cannon, more powerful:

The caliber of baril: internal diameter: 26mm and 28mm external.

The caliber of chamber : 26mm internal with 1" galva steel.

Baril lengt: 1m30.

Chamber lenght: 1m

Pressure : 150 psi for now, and 600maxi when i had my freege compressor.

Qev : 1" 1/2 tee, and a simple vavle for the exhaust.

Total lenght: 165cm

It miss le piston an the internal baril in the qev.

Pictures:

I've built a simple pen gun, for shoot bbs (pipes are glued with araldite (epoxy)):

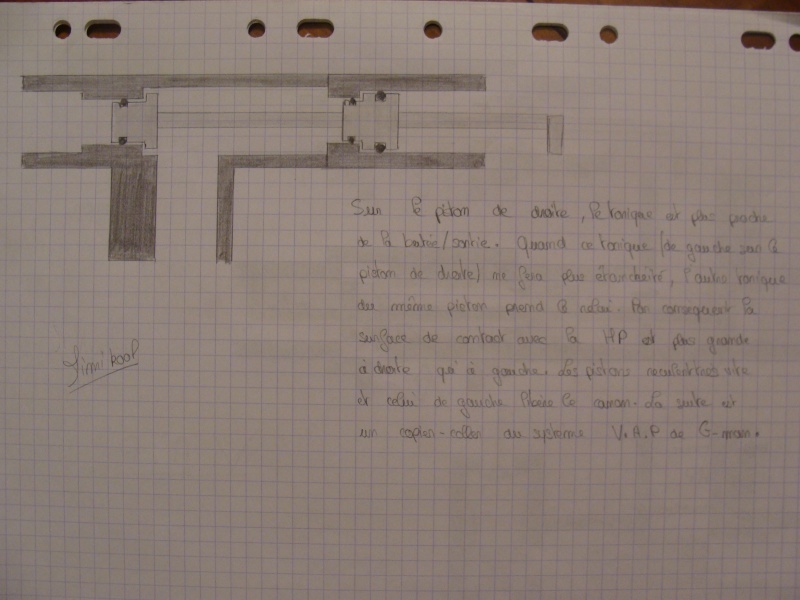

Now i'll presnt you the QDV system, the theory say that the recul of piston is really fast but it hadn't a great acceleration, because a the begining juste a little bit of air can pass in front of the piston.

So i think this system witch give the acceleration that the piston don't have, when the projectil is light for exemple.

Both piston are in link, when we press the trigger, le right piston no longer sealing and the second toric seal, larger, do the sealing, so the diameter is larger at right than at left, le piston recul and after it's a tradditional QDV.

The difficult is the built problem, requieres that the piston is screwed in the other after that system is mounted.

I hope can install this system on my first cannon.

Thanks for reading !

Apologies my bad english, i try to don't use google translate because it give not very good things, and allows me to learn english too