Brad1895 wrote:I know this will sound overkill, but I want the BEST possible range, power, ect. A 5 foot long 2" barrel powered by a 3 foot long 4" chamber.

That probably is overkill. It depends on the valve flow-rate, but very few launchers truly benefit from a 2.4:1 C:B ratio.

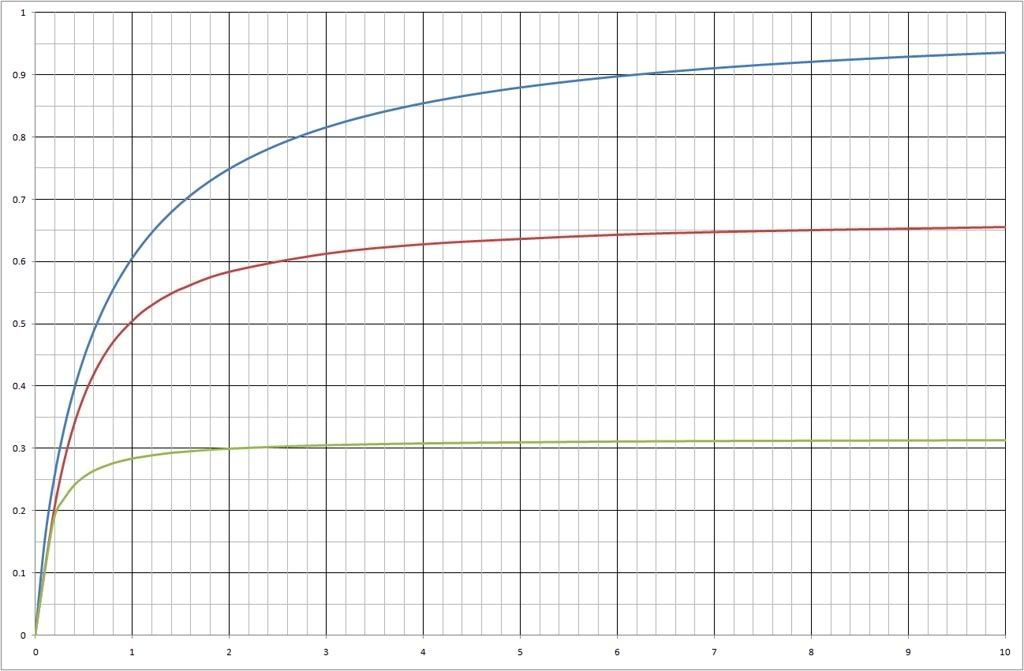

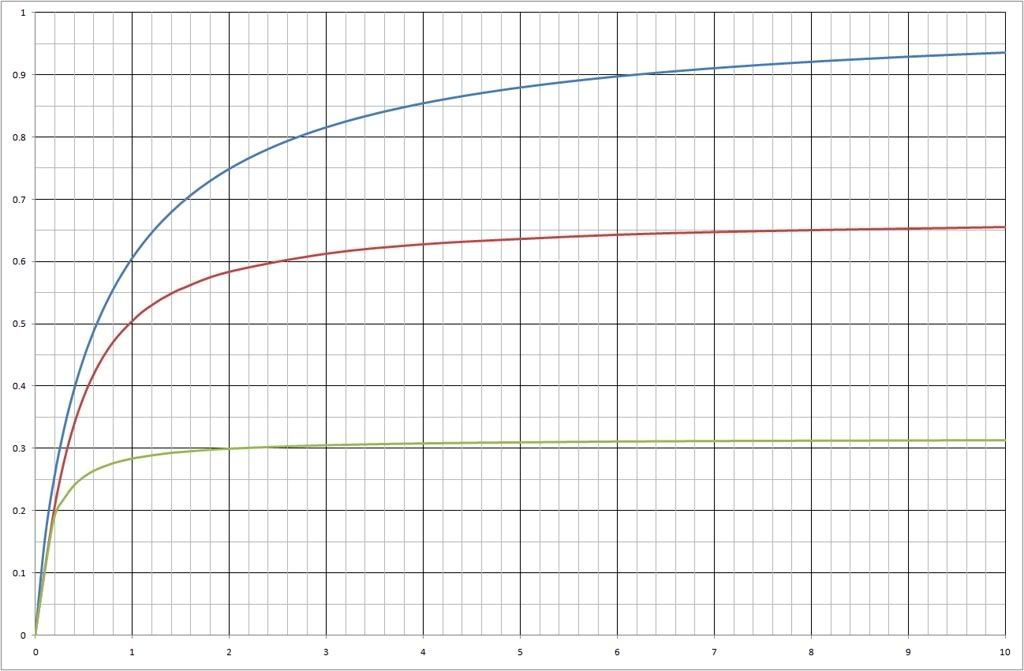

Take this diagram, which models one of my launchers:

X axis is C:B ratio (just divided through, rather than presented as a x-to-1 ratio), Y axis is the ratio of muzzle energy to the theoretical maximum (with an infinitely large chamber and infinite valve flow).

The blue line is with a valve that has infinite flow (but, as the x-axis says, without an infinitely large chamber). The red line is the predicted performance with the actual valve. The green line is if the valve diameter were halved.

As you can see, an imperfect (read: real) valve flattens the curve very quickly with high ratios. For the green line, going for a 4:1 ratio rather than a 2:1 ratio would add almost nothing to muzzle energy, but double air use.

Now, this wouldn't be too much of a worry if you had a decent compressor (provided that noise levels weren't a worry, as those would increase with air use), but as you're eventually trying to use this in a paintball game... I'd suggest something MUCH more conservatively sized, as it'll dramatically improve shot count.

Also, as Jackssmirkingrevenge keeps reminding us, the same mass of air at a higher pressure (and, ignoring temperature changes, therefore in a smaller volume) gives more energy:

jackssmirkingrevenge wrote:20 inch chamber at 50 psi - 406 feet per second

10 inch chamber at 100 psi - 537 feet per second

5 inch chamber at 200 psi - 684 feet per second

2.5 inch chamber at 400 psi - 830 feet per second

1.25 inch chamber at 800 psi - 958 feet per second

0.625 inch chamber at 1600 psi - 1006 feet per second

So, a smaller chamber you can comfortably and repeatably fill to 100 psi will give you better results than a big chamber you can only fill to 50 psi. As a general rule, I'd generally stay at less than a 2:1 ratio in a launcher and would prefer to make up the difference in extra pressure. (Eventually, the launcher you see in the graph ended up with a 1.5:1 ratio, but that's partly because it was aesthetically pleasing to have the chamber run most of the length under the barrel).

The downside is that for the same volume a higher fill pressure does impact on the amount of air an onboard tank can supply (before it drops below that pressure, anyway).

That said, whatever you do, absolutely do NOT go over a safe pressure (generous safety margin included) for your construction materials.

I think a chamber piston valve would be ideal for this, what do you guys think, what size?

I'd probably recommend a barrel sealer instead, as they're easier to construct and generally open faster because of the way the areas work.

And the answer to size is "as large as possible". Valve cross-sectional area is very important to flow, and therefore the amount of air that can actually get into the barrel to push your projectile.

Is there a noticeable difference when swapping the piston valve with a sprinkler valve?

Yes. They're slower to respond and lower flow.

One last idea that's on the back burner is to add a quarter inch connection 3" from the end of the barrel to power some kind of auto breach opening system with the extra air.

That kind of gas operation tends to not work well (if at all) at low pressures (and by low pressures, I mean "less than several hundred psi"). Also, that's quite gimmicky when you're on a tight budget.

However, if you really want to, a much better gas operation system for pneumatic spudguns is to just hitch one side of a pneumatic cylinder up to the chamber, and keep the other side under a constant pressure (lower than chamber pressure).

As chamber pressure rises and falls during filling and firing, the cylinder operates in kind.

So, what's your take on this?

In all honesty? If it's legitimate to use on your paintball field (and my guess is it might well not be*, although there was the Tippmann C-3), I'd honestly consider doing it as a combustion instead.

Pneumatics in this sort of size aren't particularly portable because of the sheer air requirements, whereas a modestly sized tank of propane would last hundreds of shots (if not thousands) and make recharging the launcher a considerably faster process.

And at "bike pump" pressures, even a piston valve pneumatic will struggle to outperform a metered combustion with good ignition and a fan - particularly if you make a quick change burst disk holder for it.

*That said, if you're using PVC, it's probably

safer to have it as a combustion. Propane does not ignite of its own accord (under normal conditions, anyway), but pressurised chambers are known to go blooey if dropped onto anything hard and/or pointy (such as many rocks that might be found on a paintball field).