Howdy Spudfolks

X-Mas is fast approaching, and in order to justify my recent spud gun obsession, I've decide to build a couple of gift guns.

My little cousin is ten years old, and he's way into Lego Bionicles. One of the weapons that these little robot guys carry is called a Zamor Sphere Launcher, which is a crossbow-ish orb shooter. I'm thinking about replicating this as a pneumatic tennisballer.

This is gonna be a low pressure cannon using an unmodified sprinkler valve, with a pop-off safety valve and other safety features. Nothing special performance-wise, but spectacular cosmetically (if it comes together like I'm picturing it.)

To make the crossbow arms, I was thinking of using a cross fitting between the valve and the breech loader/ barrel. Of course I don't want the air flowing into these arms, so I'll have to seal them off. My question is: what's the best way to do this?

In other threads people recommend cutting a piece of sheet pvc to do the job, but I honestly don't want to track down and spend the money on this stuff right now (although it would be handy stuff to have around...)

I was thinking that I could use a rubber super ball of the right size to plug the hole. Maybe epoxy it in there. Do you guys think that that'll suffice? Remember, this is gonna be after the chamber in a low pressure gun.

Any other suggestions?

Thanks in advance.

Tips for sealing off pipe?

-

Yonderknight

- Private 2

- Posts: 32

- Joined: Thu Aug 17, 2006 7:16 pm

I don't have much experience with sealing off parts of a gun, but maybe this can work?

http://www.spudfiles.com/forums/viewtopic.php?t=3834&

http://www.spudfiles.com/forums/viewtopic.php?t=3834&

You guys aren't understanding.

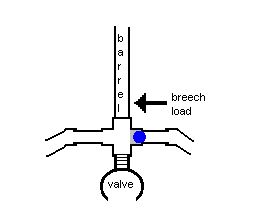

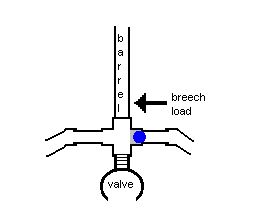

I want to seal off the airflow at the begining on the junction, keeping the flow out of the cosmetic areas. Here's a quick paint sketch:

The blue circle is the rubber superball, and that's the point where I'm wanting to put the stop.

I want to seal off the airflow at the begining on the junction, keeping the flow out of the cosmetic areas. Here's a quick paint sketch:

The blue circle is the rubber superball, and that's the point where I'm wanting to put the stop.

Last edited by Gnobbes on Fri Oct 06, 2006 12:03 am, edited 1 time in total.

-

Yonderknight

- Private 2

- Posts: 32

- Joined: Thu Aug 17, 2006 7:16 pm

Yeah, I got that much =p. I think those test-plugs should work, I mean they're made for sealing off a pipe under pressure. Even though they're for temporary testing, the barrel isn't going to be under that much pressure anyways.

- frankrede

- Sergeant Major 2

- Posts: 3220

- Joined: Thu Jul 20, 2006 9:47 pm

- Has thanked: 1 time

- Been thanked: 1 time

Put a quarter or something similiar and epoxy it like crazy.

It would be better to mod the valve.The little tike doesnt need to worry about wires and stuff. Use a 3/4 valve if you want low power.

Maybe you could mod the valve through the solenoid port so the pilot will stay the same size.

It would be better to mod the valve.The little tike doesnt need to worry about wires and stuff. Use a 3/4 valve if you want low power.

Maybe you could mod the valve through the solenoid port so the pilot will stay the same size.

Current project: Afghanistan deployment