Tips for sealing off pipe?

Posted: Thu Oct 05, 2006 9:40 pm

Howdy Spudfolks

X-Mas is fast approaching, and in order to justify my recent spud gun obsession, I've decide to build a couple of gift guns.

My little cousin is ten years old, and he's way into Lego Bionicles. One of the weapons that these little robot guys carry is called a Zamor Sphere Launcher, which is a crossbow-ish orb shooter. I'm thinking about replicating this as a pneumatic tennisballer.

This is gonna be a low pressure cannon using an unmodified sprinkler valve, with a pop-off safety valve and other safety features. Nothing special performance-wise, but spectacular cosmetically (if it comes together like I'm picturing it.)

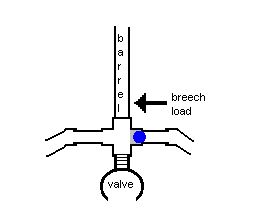

To make the crossbow arms, I was thinking of using a cross fitting between the valve and the breech loader/ barrel. Of course I don't want the air flowing into these arms, so I'll have to seal them off. My question is: what's the best way to do this?

In other threads people recommend cutting a piece of sheet pvc to do the job, but I honestly don't want to track down and spend the money on this stuff right now (although it would be handy stuff to have around...)

I was thinking that I could use a rubber super ball of the right size to plug the hole. Maybe epoxy it in there. Do you guys think that that'll suffice? Remember, this is gonna be after the chamber in a low pressure gun.

Any other suggestions?

Thanks in advance.

X-Mas is fast approaching, and in order to justify my recent spud gun obsession, I've decide to build a couple of gift guns.

My little cousin is ten years old, and he's way into Lego Bionicles. One of the weapons that these little robot guys carry is called a Zamor Sphere Launcher, which is a crossbow-ish orb shooter. I'm thinking about replicating this as a pneumatic tennisballer.

This is gonna be a low pressure cannon using an unmodified sprinkler valve, with a pop-off safety valve and other safety features. Nothing special performance-wise, but spectacular cosmetically (if it comes together like I'm picturing it.)

To make the crossbow arms, I was thinking of using a cross fitting between the valve and the breech loader/ barrel. Of course I don't want the air flowing into these arms, so I'll have to seal them off. My question is: what's the best way to do this?

In other threads people recommend cutting a piece of sheet pvc to do the job, but I honestly don't want to track down and spend the money on this stuff right now (although it would be handy stuff to have around...)

I was thinking that I could use a rubber super ball of the right size to plug the hole. Maybe epoxy it in there. Do you guys think that that'll suffice? Remember, this is gonna be after the chamber in a low pressure gun.

Any other suggestions?

Thanks in advance.