Page 1 of 1

Mach 1.6 Steam Cannon

Posted: Sun May 20, 2007 7:33 pm

by userjjb

[/img]

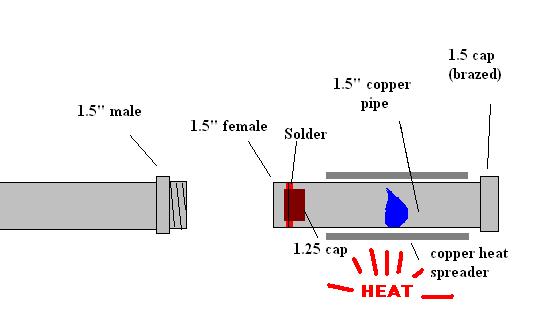

Simplicity at it's finest! Traditionally burst discs are triggered by pressure, this steam cannon instead uses a temperature triggered burst disc. The burst disc also happens to be the projectile. All fittings are brazed, if they weren't they'd fail just like the burst disc. The 1.25" cap is soldered at the end of the chamber. Heat is then applied to the chamber by a propane torch; The chamber is actually heated indirectly by way of the the heat spreader to ensure there are no hot spots.

For the particular solder used in this example the melting point is 408 degress farenheit, corresponding to a pressure of 255 psig for saturated steam.

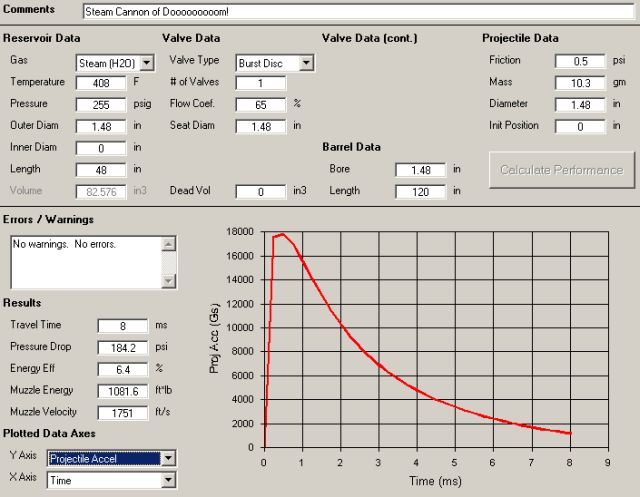

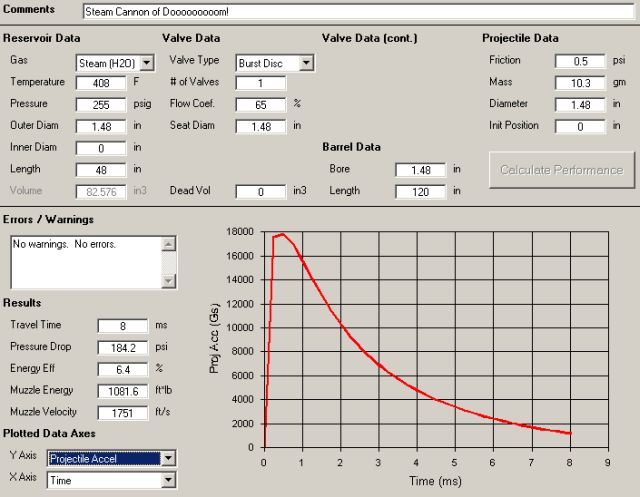

As seen in the GGDT screenshot, the steam then propels the 1.25" cap down the barrel, attaining a muzzle velocity of Mach 1.6.

Comments, concerns, or critiques?

Construction will commence tomorrow, using Type K copper.

Posted: Sun May 20, 2007 7:43 pm

by Velocity

So you are brazing all chamber connections and only soft soldering the projectile? Thats genious! I am not sure how easy it will be to get the projectile to be soldered with integrity however...

Posted: Sun May 20, 2007 8:04 pm

by Pete Zaria

I would suggest using threaded connections instead of brazing the end cap on, if possible. Lots of repeated heating/cooling cycles could eventually cause the brazed joints to fail.

Using something a bit stronger than copper might be a good idea. I like the concept a lot, though.

Peace,

Pete Zaria.

Posted: Sun May 20, 2007 9:01 pm

by userjjb

Pete Zaria wrote:I would suggest using threaded connections instead of brazing the end cap on, if possible. Lots of repeated heating/cooling cycles could eventually cause the brazed joints to fail.

I'd use all threaded/flared connections if I could, it'd allow me to keep the pressure rating on drawn copper instead of having to use the annealed temper pressure ratings, but how else am I to get the threads without brazing on threaded adapters? That would just be borrowing from Peter to pay Paul as the saying goes.

Pete Zaria wrote:Using something a bit stronger than copper might be a good idea. I like the concept a lot, though.

Ideally I'd be using welded steel, perhaps on my next generation model. I've thought about using threaded black pipe though, but I'm unsure whether the solder would hold an airtight bond on it. Not to mention black pipe doesn't have any hard and fast pressure ratings for it. For a proof of concept though I think I'll be fine, I'm within the pressure ratings on the pipe and fittings, and the actual burst pressure is a power of magnitude higher than that. Not to mention that I can remotely heat the whole assembly with little difficulty.

Posted: Mon May 21, 2007 9:36 am

by jimmy101

Interesting idea.

Couple potential problems though;

1. You don't know when it is actually going to fire.

2. If the chamber heating is uneven you may (probably will) get the solder holding the round melting unevenly. Really no reason to expect that the entire ring of solder will melt at the same time. I would expect a small portion of the solder to melt allowing the built up pressure to escape dropping the temperature of the remaining gases and the chamber. In other words, I don't think it'll work.

Posted: Mon May 21, 2007 9:49 am

by ShowNoMercy

Why not just forget the burst disk setup adn get a valve made for steam systems? That way you could generate the pressure from steam and trigger it when you want to and not have to worry about failure of joints etc. Also have you thought of superheating it?

Posted: Mon May 21, 2007 4:42 pm

by userjjb

jimmy101 wrote:Interesting idea.

1. You don't know when it is actually going to fire.

Never stopped anyone from making a traditional burst disk pneumatic.

jimmy101 wrote:2. If the chamber heating is uneven you may (probably will) get the solder holding the round melting unevenly. Really no reason to expect that the entire ring of solder will melt at the same time. I would expect a small portion of the solder to melt allowing the built up pressure to escape dropping the temperature of the remaining gases and the chamber. In other words, I don't think it'll work.

That's my main concern as well, but I'm hoping the copper heat spreader will allow even heating of the solder ring. Although why doesn't the same thing happen in traditional burst disks, that is a small portion of the disk fails and air escapes through it. I think it's because once you have a small puncture it acts as a stress concentrator allowing catastrophic failure of the material. I'm hoping that by the time the solder melts, the structural soundness of the sweat joint will already be compromised enough to fail catastrophically.

Another idea I've been tossing around is having an airtight seal between the cap and chamber and merely holing it in place with a small amount of solder, although I'd need high temp o-rings then.

ShowNoMercy wrote:[1]Why not just forget the burst disk setup adn get a valve made for steam systems? That way you could generate the pressure from steam and trigger it when you want to and [2]not have to worry about failure of joints etc. [3]Also have you thought of superheating it?

[1]I'd eventually like to make a steam piston valve for this, but this design is incredibly simple and will outperform a piston valve too.

[2]Failure of joints is always a consideration in any launcher, the only reason I mentioned that was because I can't use soldering to hold on the fittings, I'm working with temperatures above its melting point. Even if I was using a standard valve, the fittings would still have to be brazed on.

[3]Using superheated steam would be next to pointless if not detrimental. Most of the performance of the launcher comes from the pressure of the steam, not it's heat. I'd much rather have saturated steam at 448 F and 400 psi then superheating my steam to 448 F and still having only 255 psi. Not to mention the negligible performance I'd gain from superheating it also lowers my max allowable working pressure on my chamber because of the degradation of its mechanical properties.

Posted: Mon May 21, 2007 4:52 pm

by ShowNoMercy

Wow you know your stuff, I just know steam for propulsion systems, I stant corrected on the superheated steam part. You learn something new every day I guess.

Posted: Tue May 22, 2007 6:09 am

by spudthug

255 psi is alot.. so if it finds a way out its going... even the smallest, tiniest, minuscule hole it will leak like crazy... there for spewing scorching hot water... i doubt ur going to get that solder to melt at the exact time so the projectile may stay in there and all of the water will jsut come out or the endcap will topple inside..

Posted: Tue May 22, 2007 3:36 pm

by boilingleadbath

Spudthug, perhaps you failed to understand his comment about stress risers?

Anyways, I'm not compleatly sure that this seperation-propogation phenomenom will take place (melting tending to make rounded corners)... but, worst case scenario, you can always install a union.

Which I would do in the first place anyways, but that's reload rate related.

Posted: Tue May 22, 2007 8:03 pm

by spudthug

blb, what could he use for burst discs in a union? has anyone ever tried sheet metal?? but anyway i missed that stress thing..

Posted: Tue May 22, 2007 11:27 pm

by userjjb

Conventional burst discs are always a consideration too, the reason I didn't go that way at first was I figured it's be difficult to find a material that could stand up to the temperatures and pressures I'm shooting for (no pun intended).

Light gas guns use scored steel plate with good results, although my cannon won't be anywhere near as powerful as a light gas gun, I think a scaled down version might work well, although I'm not sure how expensive a convenient source would be. I know sgort used aluminum cans as burst discs in his semi-auto triggered burst disc cannon with apparently good results.

I guess the point I'm trying to make is that I'll probably need to experiment quite a bit to find something that has high performance, is cheap, and reliable. To the best of my knowledge the only thing I could find on steam cannons was the Mythbusters stuff and a similiar undertaking by MIT students collaborating with Jamie and Adam to make a <a href="

http://web.mit.edu/2.009/www/experiment ... l">working model</a>. It's a pretty unexplored area.

Posted: Thu Jun 07, 2007 2:32 pm

by potatoflinger

This is similar to something that they did on mythbusters, except theirs was huge, but it took them a long time to get it to heat up, which may be the same case as with yours. Also, when one part of the solder becomes weak and breaks through on the seal on your projectile, wouldn't it just break the rest of the seal with it?

[/img]

[/img]