I'll start off with a response to your criticism of my previous post. If you're not interested, there's a section on more "advanced" performance improvements down below.

...your comparison of a pvc vessel to a propane bottle or water heater is nearly comical...

The underlying assumption here seems to be that a spudgun is necessarily a PVC pressure vessel. This is not the case.

...there are specifically implemented safety measures to ensure safe everyday use...

As there should be in spudguns intended for entertainment, as opposed to experimental work.

The danger does not come from the operator, beyond the danger of where the operator points the gun, the danger goes to the operator, derived from the engineer telling the operator it’s safe. But as the engineer, i tell you that the PVC is in no way "thin", relatively to higher power cannons, i would accept that the PVC could be regarded as unsubstantial. The Schedule 40 pipe that i used is rated at least at 300 psi, even with the intrusions; the pipe should hold up to the 100-150 psi bursts that are experienced with propane combustion.

As regards inherent danger, I should have been more clear. I was speaking from the standpoint of the system designer who was also the system operator, as is typically the case with spudguns.

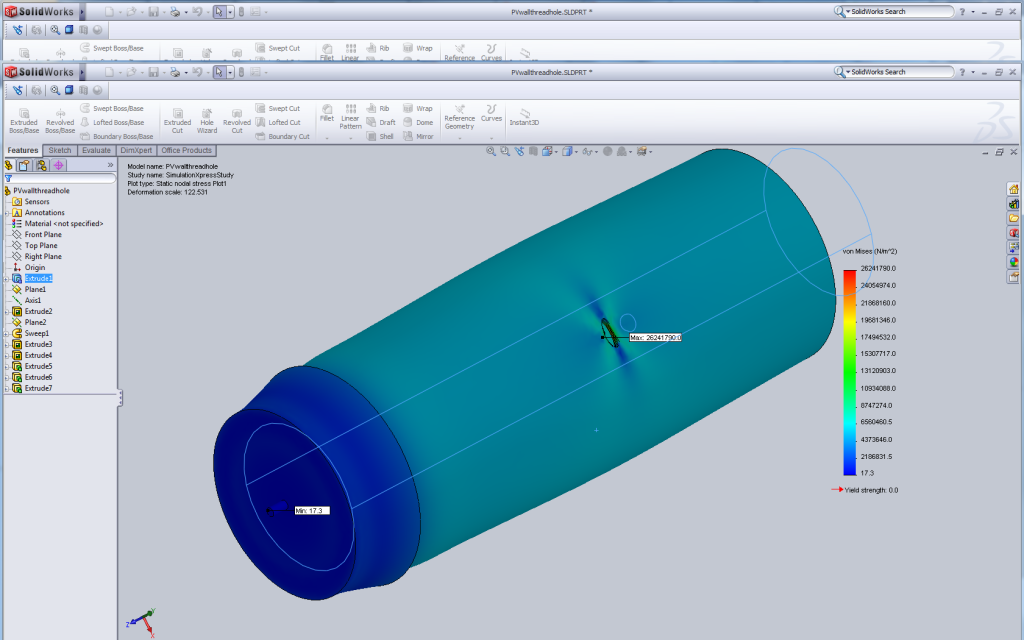

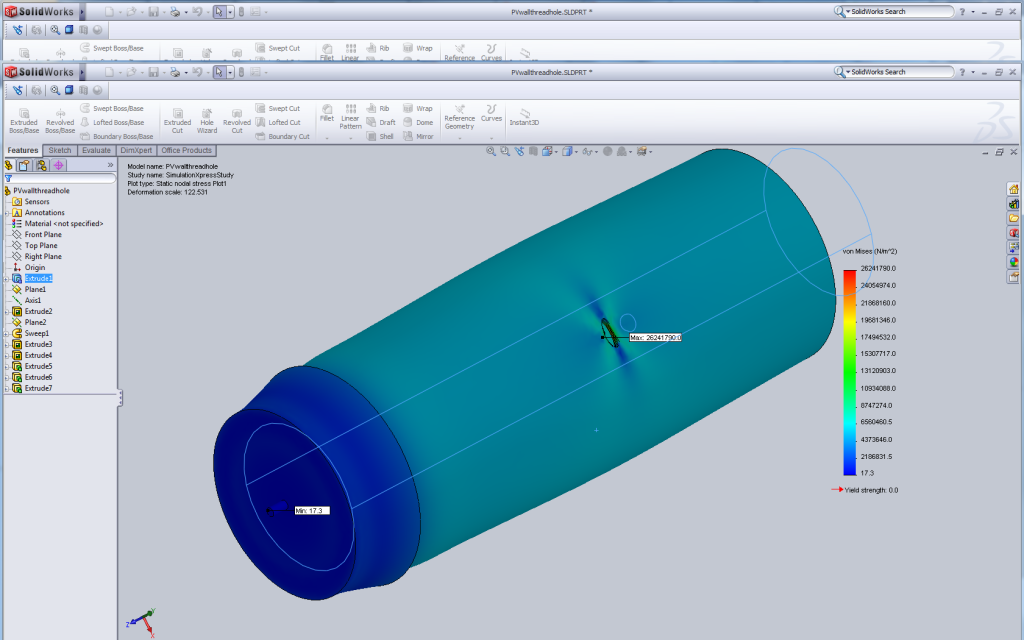

In the case of your assertion that the "intrusions" will not reduce the safety factor of the vessel to an unsafe level, I must inquire as to what FEA software you used to determine this. A quick run through Solidworks' simulation tool (which I acknowledge is far from sophisticated) indicates a stress concentration factor of approximately

FIVE at a 1/2"-20 threaded hole in the wall of a PVC pressure vessel with dimensions similar to yours (the results are shown below, with exaggerated deformation for visual effect). The maximum stress calculated was 25MPa which, while below the yield stress of approximation 40MPa, leaves you with a safety factor of less than 2 at 100psi.

You interpreted my response as hostility, despite your initial implication that spudguns were unsafe in comparison to "engineered" pressure vessels. Just because you don't engineer your pressure vessels does not make that the general case

I'm afraid that the "holy grail" you seek is not as clear cut as you would like it to be. You see, our results regarding combustion guns are all empirical, and they are quite incomplete. There are some suggestions as to further improvement I can offer, but I doubt they will be satisfactory to you. To simulate the combustion spudgun problem properly, one requires at the very least a 2D adaptive mesh CFD simulation with chemical reactions incorporated. This is difficult to write even without the chemistry, and still quite approximate due to the fact that it is still highly empirical - chemistry can be made compatible with continuum mechanics, but it isn't nice, and isn't necessarily accurate. I can give you more to chew on regarding that topic, if you're interested. To understand the problem fully would require something like a 3D CBA model. Running that model on a desktop could take

months.

What we make do with is called HGDT, a 0-D gun simulation with lots of empirical "fudge factors" to push it into line with the existing experimental data (much of it being the Burnt Latke test results). By playing with HGDT, you can attempt to optimize your chamber and barrel sizes, although it can't tell you a whole lot about fan or ignition placement.

For fan and ignition placement, it is worthwhile to consider the case of BigBang's "Crusader" design, which performed unreasonably well. You can view the thread in the archive, although the pictures no longer work. Essentially, a chamber fan near the back of the chamber with a single point ignition placed between the fan and the cap. The design appears to have induced some very favourable flame front instabilities causing rapid combustion and increased pressure generation without actually destroying the PVC launcher. He hit a launcher geometry "sweet spot" so far as anyone was ever able to tell - no measurement error was ever found.

It would also be worthwhile to switch to propylene (MAP-Pro) rather than propane. Its performance is somewhat lower than that of the old MAPP gas (which is no longer available), but it is still an improvement from propane.

If you're interested in shooting potatoes as well as golf balls, a slight bevel on the inside of the barrel (in addition to the outside bevel which functions as a "spud cutter") will improve sealing.

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

In this case a hunk of pipe had it's ID expanded to match the OD of a fitting.

In this case a hunk of pipe had it's ID expanded to match the OD of a fitting.