Now I have a simple question.

I like the "pump-action" fueling done on UltimateSpudgun's cannons, but don't understand why it takes two pumps to fuel the launchers?

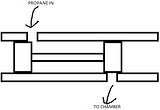

Here's what I was thinking of doing for something similar, although it would only take one press. Sorry for the diagram, but assume that there is a regulated input of propane at the top, and a check valve -> chamber connection at the bottom of the tube:

The volume between the pistons would be the meter volume on a regular setup... pushing the piston back seals off the input and injects the volume at pressure into the chamber. There could be a spring behind the spool to return it to its original position after injection.

Is there something I'm missing or does UltimateSpudgun just use a different method? I would be very interested in using this on the combustion I'm planning on building when I get my tax return, lol.

Thanks in advance for any answers!

~ Aaron