semi-auto combustion idea compressed

Posted: Sat Sep 06, 2008 12:22 pm

ok so i was just laying around thinking and i think i figured out how to make a semi-auto combustion.

to really understand this it would probably be best if you understood how an autococker paintball gun works but instead of a hammer sliding forward, an explosion goes off in the chamber

now for the gun design:

so it starts as a stacked tube design, with your barrel mounted over your chamber. I was thinking a 2.5" tennis ball barrel over a 3" combustion chamber.

in the lower tube a fan is placed in the end that will be the "front" and then that end is sealed off with whatever kind of cap you want but a threaded endcap would probably be best for this situation as it lends itself to expansion later on if needed.

both tubes are then mounted in parrellel (sp?) so the "rear" end of both are flush but DO NOT permanently mount the two in place just yet

now you need to start work on the backblock. for the bottom part of the backblock you need a rubber stopper that will completely plug the bottom tube and allow no gases to leak. for the top part you will need a bolt that is just like 99% of all paintball gun bolts so that the air can be diverted in a 90* bend. the bolt needs to slide in and out of the top bore smoothly so that it won't funk up the rythym.

next you need to take your two tubes and drill holes in them that match up with the hole that is on the side of the bolt so the expanding gases can flow from the bottom tube up through the hole and through the bolt to propel your ammo out the barrel.

after all of that matches up you can then permanently mount the barrel and chamber together.

next your going to need some electro-magnetic solenoids that have enough throw to move your bolt back enough to let your ammo drop smoothly into the bore. (in my design since a tennis ball is roughly 2.5" in diameter I will need something with at least a 2.8" throw if not upward of 3"). using at least two (one on each side of the gun but possibly more) mount them so that they will push the backblock back to vent the chamber and load another round.

now pull your backblock back to its rearmost position and drill a hole in the top for your ammo to drop through

after all that is mounted you should have a nearly finished gun. in my idea it needs a control board that controls the timing between firing and the time that the backblock opens and i was thinking possibly a copy of a paintball gun board to do this.

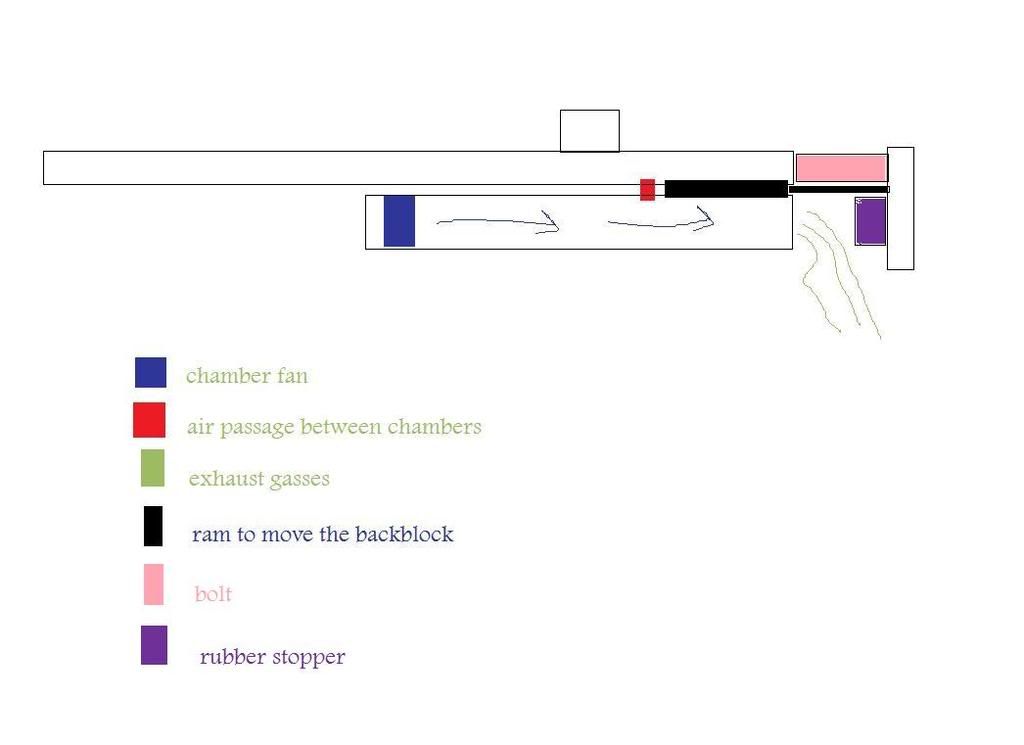

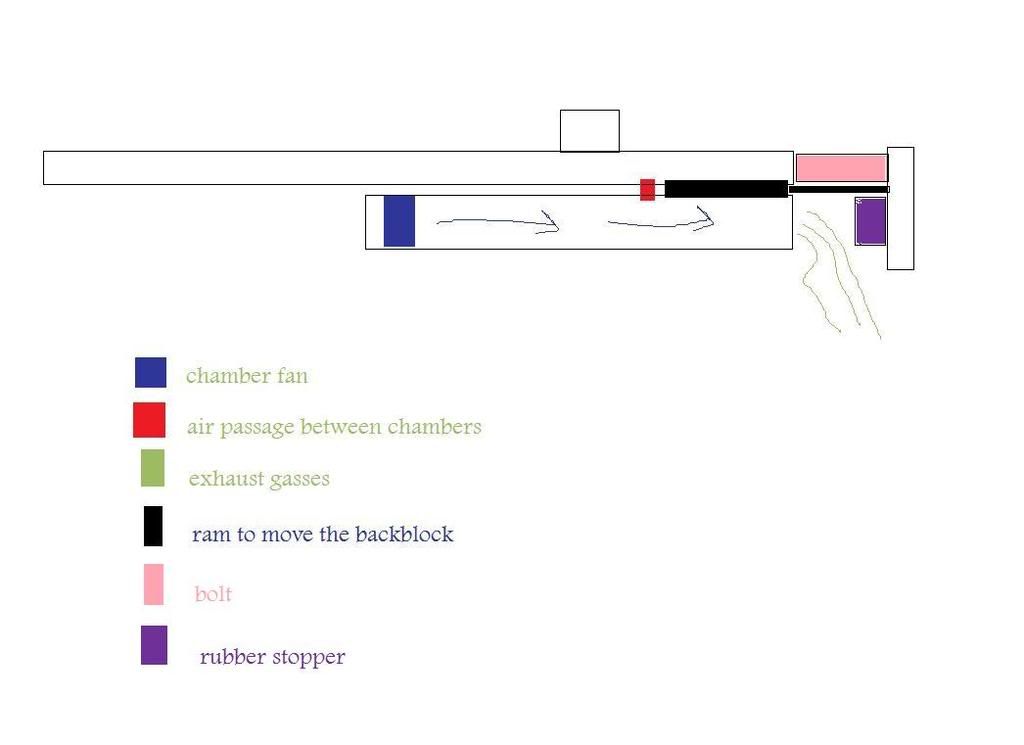

ok so this pic is after the ball has been fired.

the backblock moves back opening the breech to allow another round to drop in and it opens the combustion chamber for the unused and leftover gasses to be vented.

the red is the air passage between the two pipes for the gasses to go through the bolt when it is in the closed position. the blue is the chamber fan. and the black is whatever is used to move the backblock

and here is a cutaway of the bolt

I also have alot of minor and asthetic upgrades i would like to do if i ever get a chance to build this.

lmk what you guys think about this idea

to really understand this it would probably be best if you understood how an autococker paintball gun works but instead of a hammer sliding forward, an explosion goes off in the chamber

now for the gun design:

so it starts as a stacked tube design, with your barrel mounted over your chamber. I was thinking a 2.5" tennis ball barrel over a 3" combustion chamber.

in the lower tube a fan is placed in the end that will be the "front" and then that end is sealed off with whatever kind of cap you want but a threaded endcap would probably be best for this situation as it lends itself to expansion later on if needed.

both tubes are then mounted in parrellel (sp?) so the "rear" end of both are flush but DO NOT permanently mount the two in place just yet

now you need to start work on the backblock. for the bottom part of the backblock you need a rubber stopper that will completely plug the bottom tube and allow no gases to leak. for the top part you will need a bolt that is just like 99% of all paintball gun bolts so that the air can be diverted in a 90* bend. the bolt needs to slide in and out of the top bore smoothly so that it won't funk up the rythym.

next you need to take your two tubes and drill holes in them that match up with the hole that is on the side of the bolt so the expanding gases can flow from the bottom tube up through the hole and through the bolt to propel your ammo out the barrel.

after all of that matches up you can then permanently mount the barrel and chamber together.

next your going to need some electro-magnetic solenoids that have enough throw to move your bolt back enough to let your ammo drop smoothly into the bore. (in my design since a tennis ball is roughly 2.5" in diameter I will need something with at least a 2.8" throw if not upward of 3"). using at least two (one on each side of the gun but possibly more) mount them so that they will push the backblock back to vent the chamber and load another round.

now pull your backblock back to its rearmost position and drill a hole in the top for your ammo to drop through

after all that is mounted you should have a nearly finished gun. in my idea it needs a control board that controls the timing between firing and the time that the backblock opens and i was thinking possibly a copy of a paintball gun board to do this.

ok so this pic is after the ball has been fired.

the backblock moves back opening the breech to allow another round to drop in and it opens the combustion chamber for the unused and leftover gasses to be vented.

the red is the air passage between the two pipes for the gasses to go through the bolt when it is in the closed position. the blue is the chamber fan. and the black is whatever is used to move the backblock

and here is a cutaway of the bolt

I also have alot of minor and asthetic upgrades i would like to do if i ever get a chance to build this.

lmk what you guys think about this idea