Page 1 of 3

Need help with school project

Posted: Fri Apr 01, 2011 10:20 am

by mafaka

Hello spudfiles!

I have lurked around here for quite a while and have finally made an account so I could ask you guys a question.

I am doing a school project with a friend and the purpose of it is that we are going to investigate trajectories with force of drag.

This was an excuse so we could build a nice combustion launcher, anyway the theoretical part is done and we have now also constructed the cannon itself. We have also built a stand for it so we could test different angles and compare with our equations.

The problem is that it won't ignite.

For all we know we have done everything "by the book" (in this case spudfiles wiki) so I am hoping someone would be able to tell us what is wrong if I give you all the specs and the scenario.

Ignition:

Ignition coil and spark plug from a volkswagen

12 V car battery (recently charged when tested)

Chamber:

Inner radius of 65 mm (2,559 in)

Height of 150 mm (5,9055 in)

Volume 1,726 litres (105,30 cu in)

Barrel:

Inner radius 27mm (1,063 in)

Length ~1m (~40 in)

Fuel:

Liquid Petroleum Gas (aka LPG), it's a mixture of propane (~95%) and the rest is butane and other similar gases.

Fuel meter:

Since the LPG bottles in Sweden are regulated to only let out a pressure of 2 bar we adjusted the length to the fuel meter so that we'd get an appropriate volume if it was filled. When calculated afterwards we discovered that the fuel meter holds 4,06 % of the chamber volume.

The cannon sparks, but it won't ignite the gas we let in. We have tried to put in some more gas and we have tried if it would matter if it was anything in the barrel or not.

From what we know now it could only be the gas mixture that isn't what it should be. We are going to check the actual pressure coming out of the bottle later. Or should the spark plug be mounted in a different way? Anyway, we may have missed something you'll notice.

Thanks in advance /Mafaka

Here is some pics:

The whole assembly

http://img852.imageshack.us/i/kanon1.jpg/

http://img109.imageshack.us/i/kanon2q.jpg/

How we ignite, connect-disconnect with cables.

http://img203.imageshack.us/i/batteri.jpg/

Right side of the chamber

http://img812.imageshack.us/i/kammaresida.jpg/

What the spark plug looks like

http://img828.imageshack.us/i/tnstiftgap.jpg/

Mounted spark plug

http://img508.imageshack.us/i/tndstift.jpg/

Photo w/ spark plug, ground cable and ignition coil

http://img858.imageshack.us/i/flns.jpg/

Fuel meter

http://img263.imageshack.us/i/mtare.jpg/

Ground (yeah, literally to)

http://img18.imageshack.us/i/spikf.jpg/

Posted: Fri Apr 01, 2011 10:27 am

by Labtecpower

If the meter volume is 4,06 % of the chamber volume with a pressure of 2 bar, you will get 8,12 % LPG in the chamber. The explosion levels of propane in air are 2,1% up to 9,5 %.

I would go for a somewhat leaner mixture.

Also, do you have a chamber fan?

Posted: Fri Apr 01, 2011 10:31 am

by mafaka

In volume, the meter volume (~70 ml) is 4,06 % of the chamber volume.

So when we turn on the gas with a pressure of 2 bar, shouldn't the meter get filled with a mixture of half gas/half air since there already was air in the meter from the beginning?

Thanks for a fast reply!

Posted: Fri Apr 01, 2011 11:05 am

by Technician1002

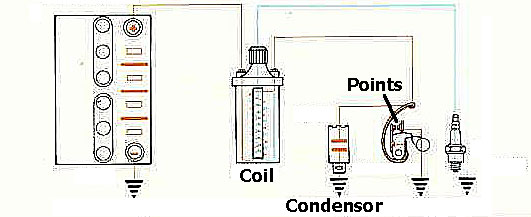

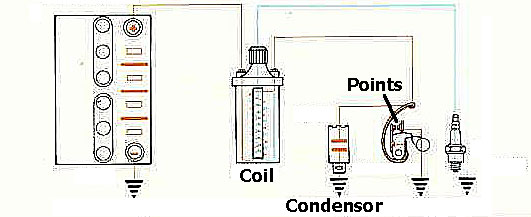

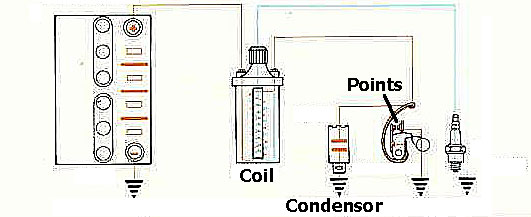

The spark will be weak (thin and very faint) with that ignition set up. Add a proper condenser from the ignition system to make a vast improvement.

The ignition will be weak without it because as you break the connection with the battery, the resulting arc at the switch prevents the high voltage pulse from forming a strong secondary voltage.

The shell of the spark plug needs a solid connection to ground. The spark current must flow somewhere. I see you provided a path with the ground on the chamber.

A Google search on Kettering ignition will show the proper placement and operation of the condenser. The condensor is an essential part of the ignition.

All the ground connections in this diagram are tied together. On a car it is the metal of the engine block.

From one page I found it is explained very well.

The condenser is a large capacitor. Only the automotive industry calls it a condenser (and no, I have no idea why). When the points open this coil collapses. Remember, a coil output is strongest when the collapse is fast and sharp. The condenser slows this collapse by absorbing the initial shock (current) of the primary winding. It helps shape the coil collapse to produce the high power secondary collapse AND slows the collapse of the coil just long enough for the points to get far enough apart so the coil back EMF output won't arc across the points. Without a condenser the backflow arcing and heat would destroy the points (sometimes in a matter of seconds). However, the condenser can't be too big either or the coil would collapse too slow and not produce a strong spark. The charge the condenser absorbs while the points are open is releases back to ground when the points close again.

http://www.jetav8r.com/Vision/Ignition/CDI.html

Posted: Fri Apr 01, 2011 11:16 am

by ramses

Chances are, the 2 bar is the gauge pressure. When you first fill the meter, you will get 1 bar of air (from the atmosphere) and 2 bar of propane (essentially).

Once you expel that, you will have 1/3 bar of air and 2/3 bar of propane in the meter. This continues until the meter is almost completely propane.

The same thing will happen if the 1 bar is absolute pressure, except that it will progress more slowly.

I really recommend you add a chamber fan and a condenser like Tech mentioned.

To test the fuel mixture, fuel the cannon without a projectile, and drop a lit match down the barrel while it is pointed in a safe direction and the match head is still burning.

Posted: Fri Apr 01, 2011 2:01 pm

by mafaka

Technician1002 wrote:The spark will be weak (thin and very faint) with that ignition set up. Add a proper condenser from the ignition system to make a vast improvement.

The ignition will be weak without it because as you break the connection with the battery, the resulting arc at the switch prevents the high voltage pulse from forming a strong secondary voltage.

The shell of the spark plug needs a solid connection to ground. The spark current must flow somewhere. I see you provided a path with the ground on the chamber.

A Google search on Kettering ignition will show the proper placement and operation of the condenser. The condensor is an essential part of the ignition.

All the ground connections in this diagram are tied together. On a car it is the metal of the engine block.

From one page I found it is explained very well.

The condenser is a large capacitor. Only the automotive industry calls it a condenser (and no, I have no idea why). When the points open this coil collapses. Remember, a coil output is strongest when the collapse is fast and sharp. The condenser slows this collapse by absorbing the initial shock (current) of the primary winding. It helps shape the coil collapse to produce the high power secondary collapse AND slows the collapse of the coil just long enough for the points to get far enough apart so the coil back EMF output won't arc across the points. Without a condenser the backflow arcing and heat would destroy the points (sometimes in a matter of seconds). However, the condenser can't be too big either or the coil would collapse too slow and not produce a strong spark. The charge the condenser absorbs while the points are open is releases back to ground when the points close again.

http://www.jetav8r.com/Vision/Ignition/CDI.html

Ok, thank you for a very explaining answer.

The circuit we have got now we got from experimenting, this setup was the best we could come up with. I don't doubt that the one you suggested is better. I will try to get a condenser and try the Kettering variant, I have a question though. Would the condenser be able to slow the collapse of the coil for so long that we would be able to use two cable ends as we do now instead of a contact breaker?

Posted: Fri Apr 01, 2011 2:18 pm

by mafaka

ramses wrote:Chances are, the 2 bar is the gauge pressure. When you first fill the meter, you will get 1 bar of air (from the atmosphere) and 2 bar of propane (essentially).

Once you expel that, you will have 1/3 bar of air and 2/3 bar of propane in the meter. This continues until the meter is almost completely propane.

The same thing will happen if the 1 bar is absolute pressure, except that it will progress more slowly.

I really recommend you add a chamber fan and a condenser like Tech mentioned.

To test the fuel mixture, fuel the cannon without a projectile, and drop a lit match down the barrel while it is pointed in a safe direction and the match head is still burning.

We'll double check if the 2 bars is the gauge pressure or not, that might as well be it.If I understood you right that would result in a total pressure of 3 bar in the fuel meter? Instead of the 2 we had counted with.

Since we don't have to fire in a rapid pace we thought we could disassemble the canon for ventilation instead of installing a fan.

We'll do the mixture test as soon as we can, that was a good idea. I'm feeling a bit dumb now since we didn't think of that.

Posted: Fri Apr 01, 2011 2:23 pm

by Labtecpower

I would try a shot with only 1 bar in the fuel meter. This will give a leaner mix, and may prove to be a better mixture than with 2 bar in the meter.

Posted: Fri Apr 01, 2011 3:07 pm

by Technician1002

mafaka wrote:

I have a question though. Would the condenser be able to slow the collapse of the coil for so long that we would be able to use two cable ends as we do now instead of a contact breaker?

A momentary connection of touching the two wires together and then separating them will do fine in place of the points. The points is just a switch operated by the cam. A connection of just a couple milliseconds is all that is required to build the coil current. The spark is when the wires separate, not when the switch is closed.

Be aware, the voltage between the wires as you separate them can exceed 300 volts. It will light your fire if you are touching them.

Posted: Fri Apr 01, 2011 3:17 pm

by Labtecpower

Be aware, the voltage between the wires as you separate them can exceed 300 volts. It will light your fire if you are touching them.

....and will leave you shaking for a few minutes

yes, I have experience :S

yes, I have experience :S

Posted: Fri Apr 01, 2011 7:02 pm

by Zeus

I'll concur, it does wake you up a little.

Unless it's because it's easier to build, why did you make a combustion? A pneumatic is much more consistant, even a metered combustion can be slightly irregular.

The fan doesn't just ventilate, it also mixes the fuel better, which can result in moar powah.

And just play with how much fuel you put in, it also doesn't hurt to revisit the maths you did. I know I've made some stupendous mistakes and simply overlooked them.

Posted: Fri Apr 01, 2011 8:39 pm

by ramses

If the tank puts out 2 bar gauge, there is 3 atmospheres of air. Eventually the air that was in the meter when you constructed it will be purged out.

At this point, you can fill it up to 2 bar gauge, and the amount that will come out under its own pressure will be 2x the volume of the meter. The last 1 bar (absolute pressure) will be the same as atmospheric pressure, and therefore stay in the tube.

Posted: Sat Apr 02, 2011 12:19 am

by mafaka

Technician1002 wrote:

A momentary connection of touching the two wires together and then separating them will do fine in place of the points. The points is just a switch operated by the cam. A connection of just a couple milliseconds is all that is required to build the coil current. The spark is when the wires separate, not when the switch is closed. Be aware, the voltage between the wires as you separate them can exceed 300 volts. It will light your fire if you are touching them.

Yes, I have some basic knowledge about electricity from school, so I know how a coil and capacitor works in theory.

But I'm not a native speaker of English so I'm not sure if I got this text you quoted right:

"Remember, a coil output is strongest when the collapse is fast and sharp. The condenser slows this collapse by absorbing the initial shock (current) of the primary winding. It helps shape the coil collapse to produce the high power secondary collapse AND slows the collapse of the coil just long enough for the points to get far enough apart so the coil back EMF output won't arc across the points."

From what I understood, when you have a contact breaker connected to the camshaft it gets going in a pace that won't allow a spark between the points. Does that make the ignition "more powerful", or how should I say it. Does it matter for my purpose if I get a spark in between the cables or not?

Posted: Sat Apr 02, 2011 12:23 am

by jackssmirkingrevenge

Have you considered

syringe metering? You'd need about 70mL of fuel for your chamber size.

Posted: Sat Apr 02, 2011 12:33 am

by mafaka

Labtecpower wrote:I would try a shot with only 1 bar in the fuel meter. This will give a leaner mix, and may prove to be a better mixture than with 2 bar in the meter.

Since we did that nice miscalculation with the pressure. (thinking it was 2 bar that went out, and therefore thinking that we would get 1 bar of air and 1 bar of LPG in the meter). We decided not to invest in a manometer. Since we don't want to spend too much money on this project, and we thought it was hard to find a manometer precise enough. What we saw in stores was like up to 6-10 bar and with every line on the measuring thingy the pressure went up with about 0,2 bar.

Zeus wrote: Unless it's because it's easier to build, why did you make a combustion? A pneumatic is much more consistant, even a metered combustion can be slightly irregular.

The fan doesn't just ventilate, it also mixes the fuel better, which can result in moar powah.

And just play with how much fuel you put in, it also doesn't hurt to revisit the maths you did. I know I've made some stupendous mistakes and simply overlooked them.

The main reason is that it is more expensive, most of the parts we have got now is donated. We don't have access to a compressor either.

I have built some simple pneumatics at home though and I now what you mean, I think they are far more reliable.

Ok, then we might should consider a fan after all. I didn't realize it was to mix the fuel.

We wondered if we might had placed the spark plug in a way that ain't optimal. You could see it on the right side of the canon in the pictures I posted.