Airsoft foam rocket launcher air magazine and valve advice

Posted: Sat Feb 27, 2010 11:19 am

Lo all (first post!)

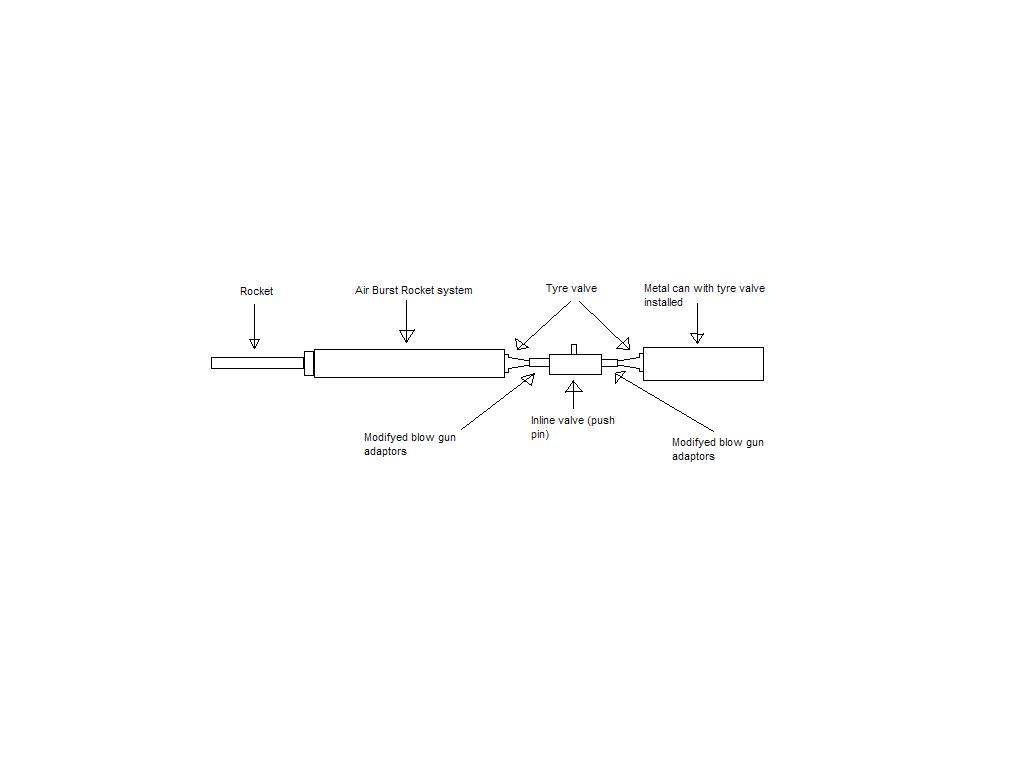

I have put together an airsoft panzerfaust 3 replica which fires a foam rocket by hacking a air burst rocket launcher

http://www.amazon.com/William-Mark-Corp ... B00019RB7K

The air tank is removed by unscrewing the tyre valve, compressing the tank with a bike pump, then rescrewed in and fired. I did it in this way to allow the use of multiple tanks (as each tank is a one shot deal)

It is currently a airburst rocket unit connected to a 10Bar inline valve which is connected to a modified deodorant can.

The air burst system and modified air tank both connect to the valve via a modified adaptor that came with an blow gun such as below.

http://www.toolshopdirect.co.uk/item.ph ... e/sn/BG01S

I want to replace the modified adaptors with something more durable, as i have found that unscrewing it to compress the tank and then rescrewing it has damaged the thread on the adaptor.

What i would really like to do is replace the entire tank and connection system to the valve.

I have decided to use 16 bar pressure rated pipe (i will only be compressing it to 9bar) for the air tank.

So i have two questions:

1) What thread would the air valve have (i am assuming 1/8 NPT?)((i have searched for a schematic from RS but haven't managed to find one))

2) What would be the best connection method to use bearing in mind that i will be removing it like a magazine (removing an uncompressed tank and replacing with a compressed one.

Many Thanks

I have put together an airsoft panzerfaust 3 replica which fires a foam rocket by hacking a air burst rocket launcher

http://www.amazon.com/William-Mark-Corp ... B00019RB7K

The air tank is removed by unscrewing the tyre valve, compressing the tank with a bike pump, then rescrewed in and fired. I did it in this way to allow the use of multiple tanks (as each tank is a one shot deal)

It is currently a airburst rocket unit connected to a 10Bar inline valve which is connected to a modified deodorant can.

The air burst system and modified air tank both connect to the valve via a modified adaptor that came with an blow gun such as below.

http://www.toolshopdirect.co.uk/item.ph ... e/sn/BG01S

I want to replace the modified adaptors with something more durable, as i have found that unscrewing it to compress the tank and then rescrewing it has damaged the thread on the adaptor.

What i would really like to do is replace the entire tank and connection system to the valve.

I have decided to use 16 bar pressure rated pipe (i will only be compressing it to 9bar) for the air tank.

So i have two questions:

1) What thread would the air valve have (i am assuming 1/8 NPT?)((i have searched for a schematic from RS but haven't managed to find one))

2) What would be the best connection method to use bearing in mind that i will be removing it like a magazine (removing an uncompressed tank and replacing with a compressed one.

Many Thanks