M16 Inline Vortex BBMG

Posted: Sun Jun 06, 2010 12:36 pm

It is finally complete! Details and build log can be found below. Here are the latest pics.

My favorite picture-

Best video:

[youtube][/youtube]

Specifications:

Barrel: 25 inches 6.35mm brass.

Chamber: 10 inches 2" sch 40 PVC.

Valve: Standard blowgun.

Inlet: Quick connect.

Vortex block: Wood, 1" hole reinforced with pvc interior.

Operating pressure: 100 to 180 psi.

Total length: 39 inches (same as real M16)

Velocity: Chrony'd 350 fps with .20 gram bb.

Other pictures.

Updates as of 8/16/2010 at bottom

NEW VIDEOS AT BOTTOM

It isn't completely done, but I wanted to post it anyway. It is funcional though, I have a video here:

[youtube][/youtube]

---------------------------------------------------

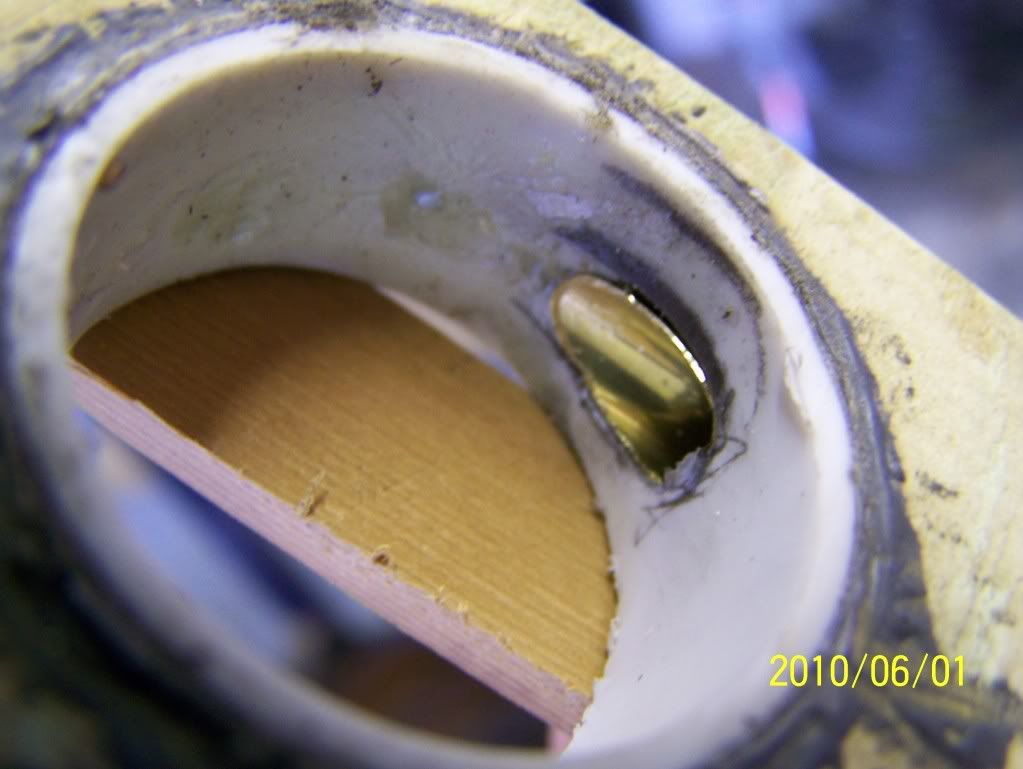

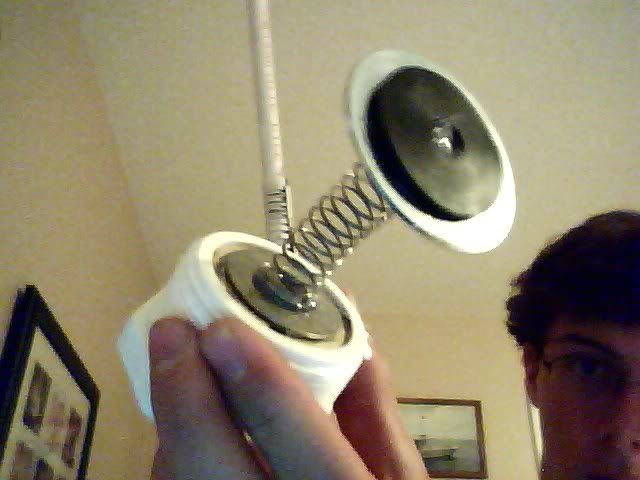

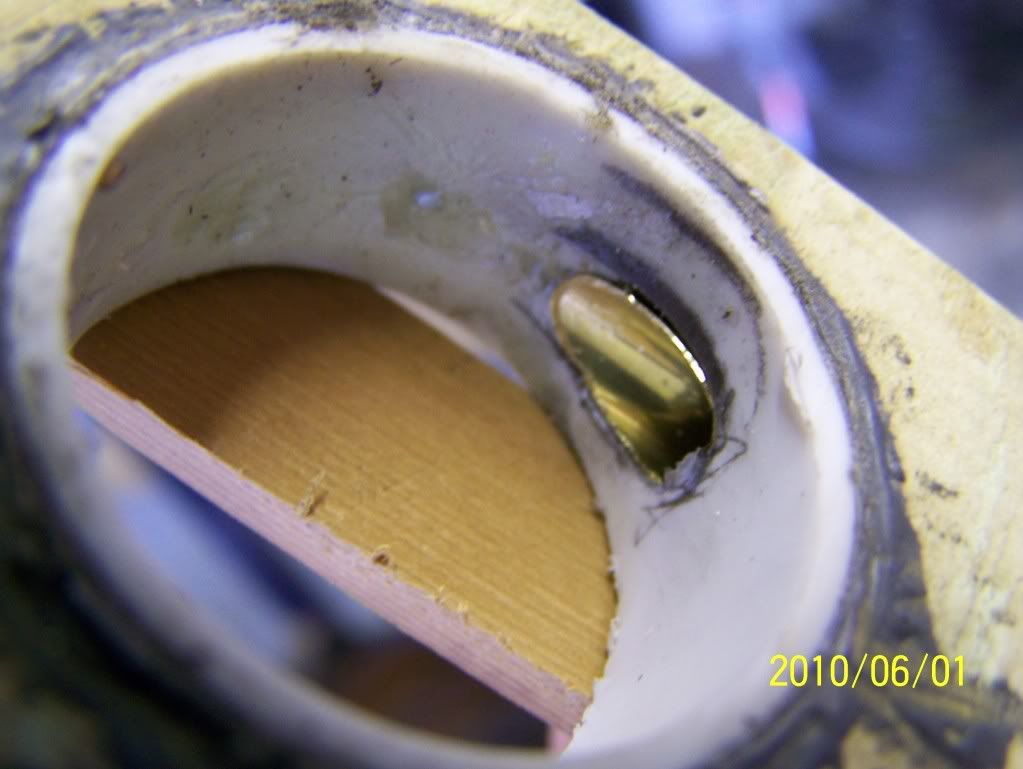

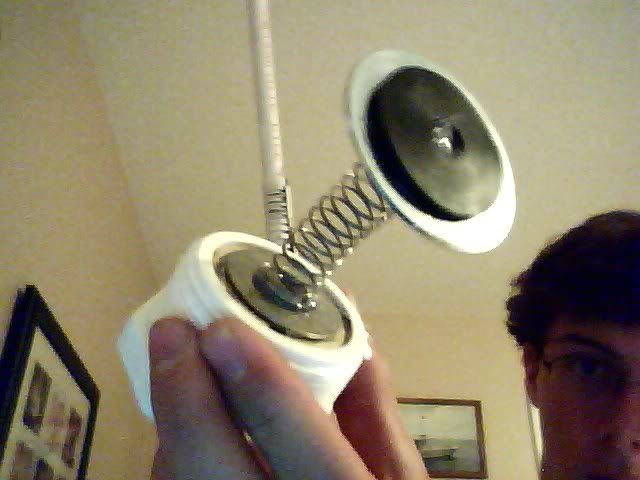

After the original prototype, I lengthened the chamber with another coupling, I wanted to keep the whole thing flush. I added a spring plunger for better feeding also, because in the video you can tell there were a lot of issues. I also changed the valve to a more comfortable setup. The only problem I am still having with funcionality is the front plug not sealing. I wrapped it with teflon tape and held it in with screws, but air rushes out of it still. I need ideas for sealing this, I am thinking a rubber gasket or an o-ring. Anyway, here's a couple pics:

Internal-

External-

Mock flash suppressor, compare to this one on the M16-

Mine-

Way too overcomplicated plunger-

New pics-

Front-

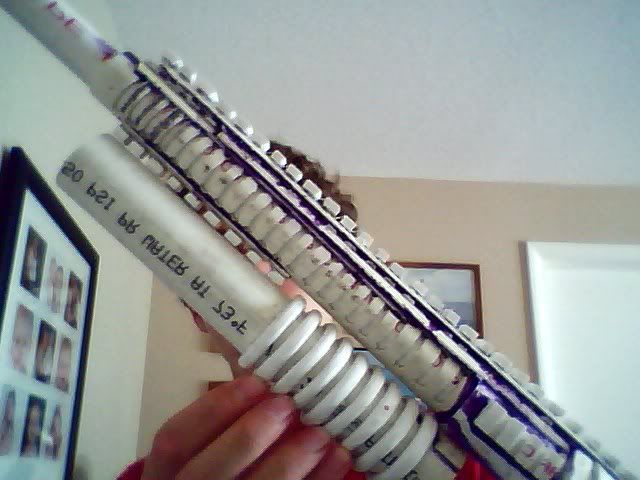

With new rails-

Mock M203-

Where it will go-

Just need to fix it on, probably with hot glue or weld it. Welding it would be a pain in the arse though.

Updates to come, very soon. I promise

Update 1:

Ok I added a new part to the M203-

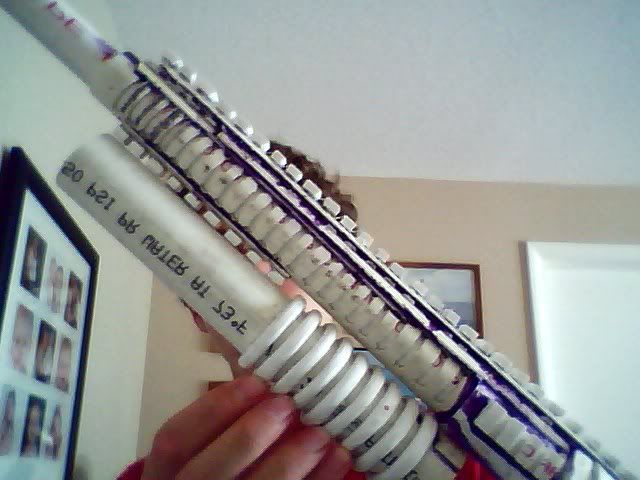

Just want to add, the M203 is 1" thick walled PVC, the rings are 1.25" cut with a hack saw and grinded to a curve individually, which took a while.

Update 2:

Mounted M203 and added a pistol grip to the blowgun, making the gun very comfortable to hold.

Left to do:

Add stock, complete reciever with mag, add sights, seal the leak, paint. The end is in sight...

Update 3:

Added a mag holder, not a mag yet though. Also an old trigger I had went onto the reciever so that the trigger wouldn't feel upside down, it is very comortable now.

Left to do-

Add stock, carve mag, add sights, seal leak, paint.

Update 4:

Two new videos here:

[youtube][/youtube]

[youtube][/youtube]

And some new pics, I installed a front sight, foward assist and stock!!! Man this thing is really looking sexy if I do say so myself... anyway, the front sight is molded 1.5" PVC, foward assist is carved wood and a bolt, stock is molded 2" PVC, here's the pics.

Foward assist-

Front sight-

Stock!!

Oh and I also put a mag in the holder, it is carved wood. Used a razor and dremel. It is all installed on the new gun, pic here-

Now I need a rear sight, fix the front plug leak as soon as I can get to ace, and paint it!!!

Update 5-

New video.

[youtube][/youtube]

UPDATE 6!! THE BIG ONES!!!

New mag made, took forever but very rewarding. It looks great. It is sheet pvc that I made. The grooves down the sides were made with a dremel.

The rear iron sight, which isn't very iron

It is also sheet pvc that I made. I think it looks awsome too.

It is also sheet pvc that I made. I think it looks awsome too.

Comfy butt pad, made of garden hose cut down the middle. Pretty ghetto but it's better than seeing the hollow inside of the stock.

And I came up with a little rail system that allows me to quickly switch between attachments. It is just machined PVC. You can see how it works in the pics.

And lastly, the fire extinguisher tank that I've been dying to make for a long time. It holds a bunch of air and gives me a long period of firing. It just has a small leak that I need to fix.

Just need to paint it now, ordering krylon fusion camo after vacation, so it'll be a few weeks until it's done.

Today I felt like redoing the muzzle break/flash suppressor because the old one was messed up. This one came out very nice.

:occasion5:

Newest pictures and a video of the completed gun at the top of the thread.

My favorite picture-

Best video:

[youtube][/youtube]

Specifications:

Barrel: 25 inches 6.35mm brass.

Chamber: 10 inches 2" sch 40 PVC.

Valve: Standard blowgun.

Inlet: Quick connect.

Vortex block: Wood, 1" hole reinforced with pvc interior.

Operating pressure: 100 to 180 psi.

Total length: 39 inches (same as real M16)

Velocity: Chrony'd 350 fps with .20 gram bb.

Other pictures.

Updates as of 8/16/2010 at bottom

NEW VIDEOS AT BOTTOM

It isn't completely done, but I wanted to post it anyway. It is funcional though, I have a video here:

[youtube][/youtube]

---------------------------------------------------

After the original prototype, I lengthened the chamber with another coupling, I wanted to keep the whole thing flush. I added a spring plunger for better feeding also, because in the video you can tell there were a lot of issues. I also changed the valve to a more comfortable setup. The only problem I am still having with funcionality is the front plug not sealing. I wrapped it with teflon tape and held it in with screws, but air rushes out of it still. I need ideas for sealing this, I am thinking a rubber gasket or an o-ring. Anyway, here's a couple pics:

Internal-

External-

Mock flash suppressor, compare to this one on the M16-

Mine-

Way too overcomplicated plunger-

New pics-

Front-

With new rails-

Mock M203-

Where it will go-

Just need to fix it on, probably with hot glue or weld it. Welding it would be a pain in the arse though.

Updates to come, very soon. I promise

Update 1:

Ok I added a new part to the M203-

Just want to add, the M203 is 1" thick walled PVC, the rings are 1.25" cut with a hack saw and grinded to a curve individually, which took a while.

Update 2:

Mounted M203 and added a pistol grip to the blowgun, making the gun very comfortable to hold.

Left to do:

Add stock, complete reciever with mag, add sights, seal the leak, paint. The end is in sight...

Update 3:

Added a mag holder, not a mag yet though. Also an old trigger I had went onto the reciever so that the trigger wouldn't feel upside down, it is very comortable now.

Left to do-

Add stock, carve mag, add sights, seal leak, paint.

Update 4:

Two new videos here:

[youtube][/youtube]

[youtube][/youtube]

And some new pics, I installed a front sight, foward assist and stock!!! Man this thing is really looking sexy if I do say so myself... anyway, the front sight is molded 1.5" PVC, foward assist is carved wood and a bolt, stock is molded 2" PVC, here's the pics.

Foward assist-

Front sight-

Stock!!

Oh and I also put a mag in the holder, it is carved wood. Used a razor and dremel. It is all installed on the new gun, pic here-

Now I need a rear sight, fix the front plug leak as soon as I can get to ace, and paint it!!!

Update 5-

New video.

[youtube][/youtube]

UPDATE 6!! THE BIG ONES!!!

New mag made, took forever but very rewarding. It looks great. It is sheet pvc that I made. The grooves down the sides were made with a dremel.

The rear iron sight, which isn't very iron

Comfy butt pad, made of garden hose cut down the middle. Pretty ghetto but it's better than seeing the hollow inside of the stock.

And I came up with a little rail system that allows me to quickly switch between attachments. It is just machined PVC. You can see how it works in the pics.

And lastly, the fire extinguisher tank that I've been dying to make for a long time. It holds a bunch of air and gives me a long period of firing. It just has a small leak that I need to fix.

Just need to paint it now, ordering krylon fusion camo after vacation, so it'll be a few weeks until it's done.

Today I felt like redoing the muzzle break/flash suppressor because the old one was messed up. This one came out very nice.

:occasion5:

Newest pictures and a video of the completed gun at the top of the thread.