Page 1 of 1

Slide valve or 3-way valve?

Posted: Mon Oct 08, 2012 4:06 pm

by junebug

Which is better for a HPA qev semi-auto setup?

If my qev can handle over 3000 psi what is a realistic firing pressure? I think I've seen commerical hpa rifles that are regulated down to 1500 psi. I'm having trouble finding a slide or 3-way valve that can handle 1500 psi or higher!

Can anyone help me out? Suggestions or just some realistic expections as far as actual psi upon firing...

Thanks and sorry for newb questions... oh, and haven't decided on caliber but leaning towards .22 pellets.

Posted: Mon Oct 08, 2012 4:17 pm

by POLAND_SPUD

get a slide valve for paintball guns

Posted: Mon Oct 08, 2012 10:26 pm

by jackssmirkingrevenge

First off, a slide valve is a three way valve, and is perfect as a pilot for a QEV, one of the reasons is that you need to push the slide to the rear to fire, so if your QEV is mounted horizontally as most are, you get a natural trigger movement.

As POLAND says, these will do:

The can take 4500 psi safely, and quite cheap off eBay:

http://www.ebay.com/itm/Ninja-Air-Paint ... 2c64ef6d4d

http://www.ebay.com/itm/Paintball-Repla ... 27c02404fe

If my qev can handle over 3000 psi what is a realistic firing pressure? I think I've seen commerical hpa rifles that are regulated down to 1500 psi.

A QEV-slide valve setup will typically dump more air at a higher flow rate than the hammer valve on commercial rifles, so you don't need as much pressure.

Here's a GGDT simulation using less than 1 cubic inch chamber size and 1000 psi, you get quite high velocity for a medium weight 0.22" pellet and almost 20 ft/lbs of muzzle energy. To put that into context, any air rifle over 12 ft/lbs in the UK has to be registered as a firearm.

For that simulation I assumed a "rifle sized" two foot barrel and a poor reloading system with one cubic inch of dead space. Naturally by lengthening the barrel, making the chamber larger, reducing dead space etc. you can get more performance without increasing pressure.

The question is what are you looking to destroy and at what range

Posted: Tue Oct 09, 2012 10:48 am

by wyz2285

Jack, Poland, have you ever used a paintball slide valve to trigger a QEV above 1000 psi?

Because these slide valves maybe rated to 3000 psi (the materials), but that doesn´t mean it can operate at that pressure. My paintball slide valve(same as the second picture/link) started to leak after I use it twice at 1000 psi, the o-ring got wasted on the exhaust port. There is no way any slide valve can survive constant open/close at 3000 psi.

Posted: Tue Oct 09, 2012 7:55 pm

by junebug

Cool, thanks Jack, Poland, and wyz. You guys have been really helpful. This has answered my question and more. I wanted to go longer than 24" rifled barrel if I can find one but will settle with what is available.

I guess I will have to experiment with the slide valves and cross my fingers that it'll hold up.

Anyone have experience with a specific brand that can hold up to repeated 1000 psi or more use?

Posted: Tue Oct 09, 2012 8:20 pm

by apocavorme

Im buying this one:

http://www.ebay.com/itm/390478816145?ss ... 1439.l2649

The seller told me that it can handle 10MPa (1450 psi); what you guys think?

The thread is G1/2 (cilindrical bsp i think.)

About the o-ring, if you keep it very lubricated, i think it would last long.

Does these remote slide valves have enough flow to pikot a 3/4 qev(19mm diam piston/ 16mm diam seat)?

Posted: Tue Oct 09, 2012 10:12 pm

by Lockednloaded

jackssmirkingrevenge wrote:

I've used this particular slide valve at 2000psi with those "3/4inch" ebay square style QEVs, so they should be safe to use at about 1000 psi with a decent safety margin.

I personally haven't experience the problem wyz describes with this slide valve, and although it becomes harder to actuate at extreme pressures, it has never leaked on me (I actually have two ATM on different projects) and is always consistent. With a "trigger" addition that gave me some leverage, I was able to comfortably actuate this valve semi automatically. at 700psi

Posted: Tue Oct 09, 2012 10:55 pm

by jackssmirkingrevenge

wyz2285 wrote:Jack, Poland, have you ever used a paintball slide valve to trigger a QEV above 1000 psi?

Because these slide valves maybe rated to 3000 psi (the materials), but that doesn´t mean it can operate at that pressure. My paintball slide valve(same as the second picture/link) started to leak after I use it twice at 1000 psi, the o-ring got wasted on the exhaust port. There is no way any slide valve can survive constant open/close at 3000 psi.

I used mine (that looks like the type in the first picture, and the one LnL described) many times at 850 psi and never have leaks.

Have you ever taken yours apart to look at the exhaust port? It could be poorly finished, hence the tearing of o-rings. I would recommend dismantling it and putting a slight bevel on the hole to reduce wear and tear, and indeed if you have the facilities, drill a few more small holes to improve exhaust flow.

I wanted to go longer than 24" rifled barrel if I can find one but will settle with what is available.

You can compromise by having say a 24" length of smoothbore barrel, and a 12" rifled barrel at the end. If you manage to align them this should work just as well. Also note that "diablo" or shuttlecock shaped pellets of medium weight (approx 16 grains/1 gram for 0.22") will usually fly pretty straight even without rifling because of their form and weight distribution.

Anyone have experience with a specific brand that can hold up to repeated 1000 psi or more use?

I think even a generic one would be good if you take a look at the exhaust port before using it and see if it needs some attention.

If you want a good brand, and at the same time support the US economy, I would recommend Ninja:

http://www.ebay.com/itm/Ninja-Slide-Che ... 35ba4924d8

I have two of their bottles and the build quality is nice, I would assume they pay the same attention to all their products.

About the o-ring, if you keep it very lubricated, i think it would last long.

It's not about lubrication, more about interaction with the exhaust ports. if they are poorly finished or have no

bevel on them, they will act like a blade and rapidly tear the o-ring

Does these remote slide valves have enough flow to pilot a 3/4 qev(19mm diam piston/ 16mm diam seat)?

Definitely. As QEVs have parachute/umbrella type pistons, you can pilot them with a schrader if you want.

Posted: Fri Oct 12, 2012 1:00 pm

by junebug

Thanks for all the info guys. I ordered a ninja slide valve 1/8 npt and a "ebay" QEV 1/2 npt. I tried to contact the maker of the high pressure qev but haven't heard back from them and I suspect they are pretty pricey or only sell in bulk. So hope this ebay qev holds up.

http://cgi.ebay.com/ws/eBayISAPI.dll?Vi ... OTORS:3160

http://cgi.ebay.com/ws/eBayISAPI.dll?Vi ... OTORS:3160

I'll try testing it around 200-500psi before purchasing a tank, regulator, and barrel. Then convince my friend(who owns a CNC shop) to make a breech and blow forward bolt which I'm designing right now. Got some rough sketches but I'll do a clean illustrator version and post up to see what you guys think.

Thanks again!

Posted: Fri Oct 12, 2012 2:10 pm

by jackssmirkingrevenge

If it's stainless it should hold up nicely, the weak link is the piston itself. Open it up and see what it looks like, if you have the benefit of CNC you can machine your own replacement pistol if the stock one is not up to it.

Posted: Fri Oct 12, 2012 6:08 pm

by junebug

jackssmirkingrevenge wrote:If it's stainless it should hold up nicely, the weak link is the piston itself. Open it up and see what it looks like, if you have the benefit of CNC you can machine your own replacement pistol if the stock one is not up to it.

The body is aluminum. Will it hold up and not explode in my face? I suspect the piston will be the weak link but if it fails it should just leak or not function right? So if I need to machine a replacement piston would aluminum be ok or do a stainless steal and call it a day.

Posted: Sat Oct 13, 2012 12:14 am

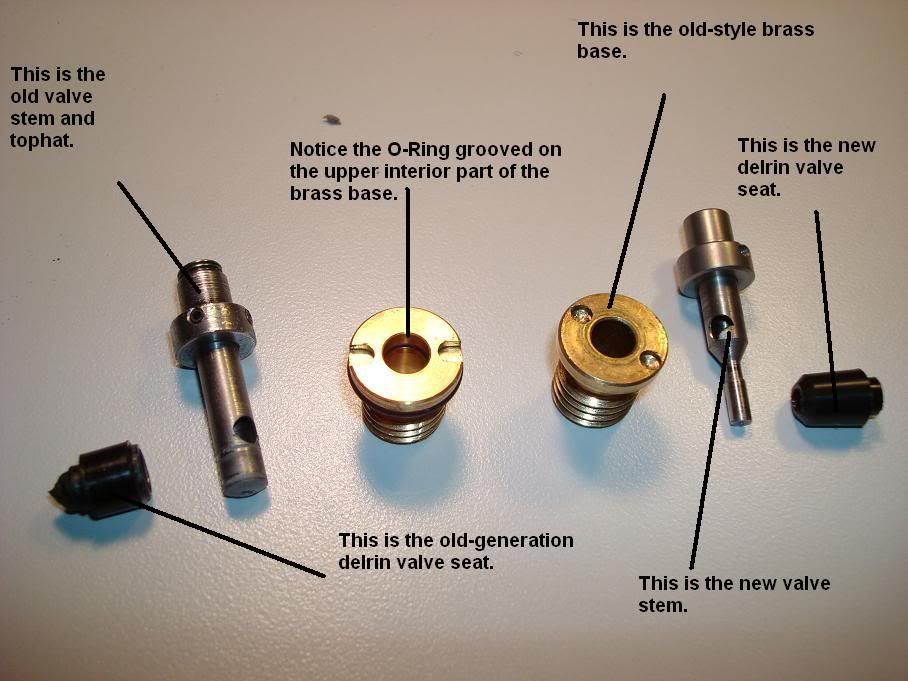

by jackssmirkingrevenge

Posted: Sat Oct 13, 2012 7:40 pm

by junebug

Awesome, thanks for the photos. I would have never thought to use delrin but makes sense since it's durable and light weight. Even better, I still have some delrin stock left over from one of my streetbike projects. Can't wait to get the hardware!