Page 1 of 2

Barrel problems

Posted: Tue May 27, 2014 12:03 am

by iv_meneses

I have problems trying to find a barrel

I´ve made a full semi automatic system with DCV and QEV, I have the tank and necesary regulators, my only problem is the barrel. As this is my second gun, I wanted to make it great, so I don't want to be making its own ammo, I rather use common ammo, there is where the problem begins, I can't find any cheap 0.22 or 0.177 barrel and machining it from a steel rod is not an opcion because it will cost over $120. Any good ideas?

I am currently using a 3/8 aluminum tube but I just don't go along with home-made ammo

Thanks in advance and sorry for any spelling or gramatical errors, I am from Costa RIca and English is not my native language.

Re: Barrel problems

Posted: Tue May 27, 2014 7:37 am

by jackssmirkingrevenge

If you search online you should be able to find a 5.5mm internal diameter brass or aluminum tube.

Re: Barrel problems

Posted: Tue May 27, 2014 1:15 pm

by iv_meneses

Thanks, I just found in this website someone saying that I could find them in macmaster, I'll probably buy it from there, sadly it will take about 20 days shipping. Do you think that 0.025" or 0.003" will really make the difference between the barrel ID and the pellet diameter?

Re: Barrel problems

Posted: Tue May 27, 2014 3:01 pm

by jackssmirkingrevenge

You will lose power and more importantly, accuracy.

Is your country well served by eBay?

Re: Barrel problems

Posted: Tue May 27, 2014 10:56 pm

by iv_meneses

Ahmm I am not sure, most people I know prefer amazon...

Re: Barrel problems

Posted: Wed May 28, 2014 4:22 pm

by Brian the brain

You could keep a section of that barrel to mould the pellet to a snug fit.

Put in the pellet and set it on a flat surface.

Now gently tap the pellet on the head with the back of a drillbit to make the skirt expand.

Be sure to deburr the section of tube!

Just ask JSR..

Re: Barrel problems

Posted: Thu May 29, 2014 10:20 pm

by iv_meneses

Drillbits are the screw-like things you put on the drill to cut in holes? And wouldn't that method leave the head of the pellet nonfitting to the barrel?

If I post a paint picture of my desing and then an actual picture of the "rifle" so far, would you mind checking it? It is still lacking the stock and the reloading mechanism, which I already have an idea how to desing but without the actual barrel is nonsense making it right now.

Re: Barrel problems

Posted: Fri May 30, 2014 2:49 pm

by Brian the brain

Checking out designs is what we do around here, I'm just not always around..

What I meant is the drill itself.

The head of the pellet is already very close to the dimeter you want right?

I don't think this method will give you any real problems, but if you try it you will see if it works well enough for your needs.

Re: Barrel problems

Posted: Fri May 30, 2014 5:57 pm

by vng21092

check this out

http://www.amazon.com/Stainless-Steel-S ... EX83HQF2N6 Here is a picture of the .177 (ID:0.18'') barrel I bought from that selection, fits REALLY nicely. Hope you find something there

Re: Barrel problems

Posted: Fri May 30, 2014 8:58 pm

by iv_meneses

The amazon option seems a lot better so I'll try that one and buy a .18 ID and .23 ID so I can make exchangable barrels later. Thank you very much

Now, regarding the pictures:

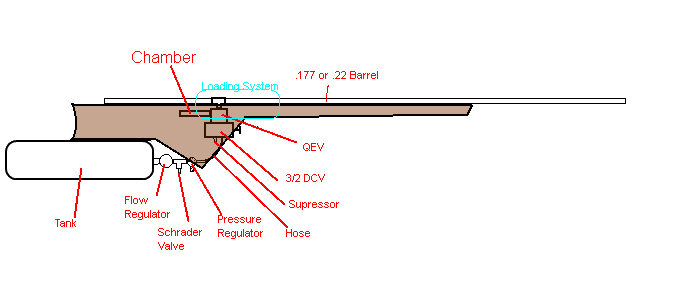

- Desing.png (6.29 KiB) Viewed 6424 times

This is more less how I intend it to be when finished

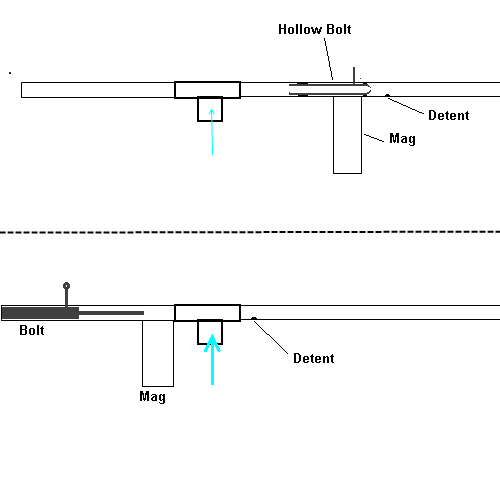

- Load Desing.png (5.43 KiB) Viewed 6424 times

These are the two options I have for the reloading system, I believe they are self explained, I could really use help deciding because it's the first time I'll try a non muzzle load desing.

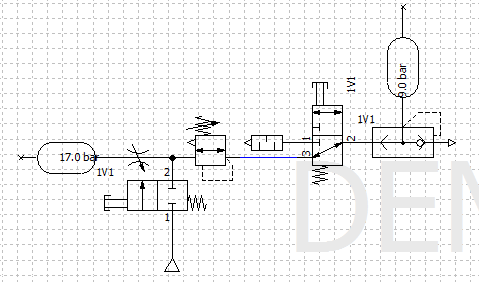

- Grafcet Desing.PNG (13.09 KiB) Viewed 6424 times

This one is a grafcet view of how it works

This is the project so far. The "barrel" is attached just for testing purpouses and it's still lacking stock, real barrel, and the trigger which will be instead the 3/2 DCV button.

Any grammar or spelling correction will be apreciated, as I said before my native language is spanish, I learned english in highschool

Re: Barrel problems

Posted: Thu Jun 05, 2014 3:06 pm

by Dr Krieger

Re: Barrel problems

Posted: Thu Jun 05, 2014 4:14 pm

by Brian the brain

I like the second design, where the bolt goes through the mag first and then loads the ammo into the Tee where the air comes in.

I've used that before and it works well.

You need just one O-ring to seal the bolt.

I'm not a fan of hollow bolts.

They restrict the airflow and require O-rings in two places to be sealed.

Re: Barrel problems

Posted: Thu Jun 05, 2014 11:50 pm

by iv_meneses

Yes, I believe that the second one is better but I am clueless about how to make either, so any idea on how to make the very bolt? I mean a bolt about 0.18" or 0.23" diameter with an even smaller pin that pushes the pellet further does not sound easy to make, just saying :/

But the coolest part of the second one is that easely once made it can be modified to become part of the air chamber and work as an air cylinder (spring return or air spring return) and make the gun be real semi-auto.

Re: Barrel problems

Posted: Sat Jun 07, 2014 7:04 am

by vng21092

if you go with the .18'' barrel like I did, super glue an o-ring to the top of the barrel where the I.D of the o-ring is just a TINY bit smaller than the barrel, then find a 8/32 bolt and apply a piece of heat shrink tubing over it. With just a little grease the bolt should slide freely into the barrel while sealing it at the same time. For the smaller tip at the end of the bolt just use a grinder, if you don't have a grinder just sand it down.

Re: Barrel problems

Posted: Wed Jun 11, 2014 7:31 am

by jackssmirkingrevenge