Breech Loader

Posted: Tue Jul 29, 2008 12:46 am

Alright, been brewing over a design in my head for a week now, rough sketches flood my notebooks, so I wanted to get everyone else's opinions before I splurged and went to Lowe's for all the things I'd need.

I'll apologize ahead of time for no sketches uploaded, my scanner hates me, and Google Sketch-up has been beating me over the head for a week now, so no 3-D models either.

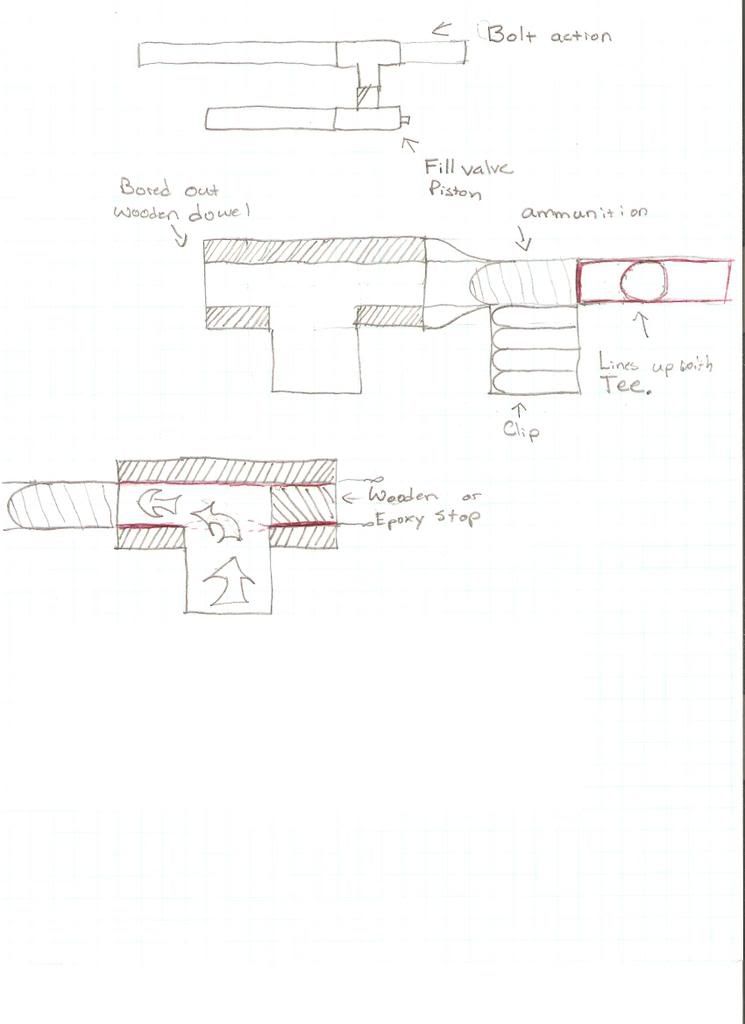

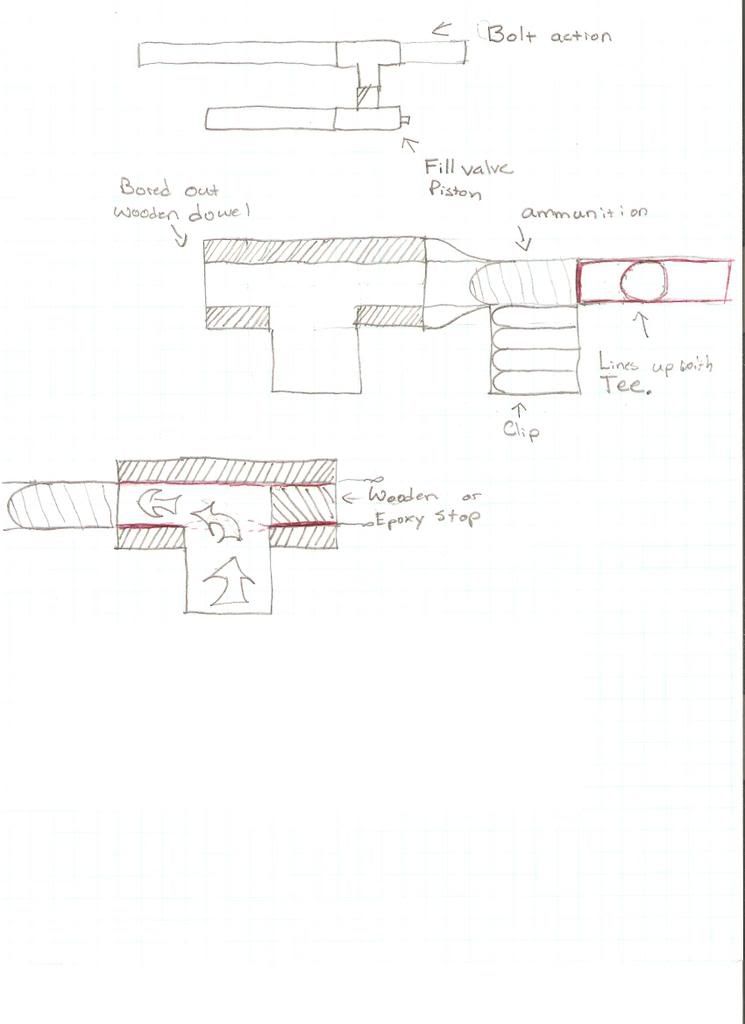

Essentially it would be an over under, chamber-sealing piston -QEV, not sure which is best suited for my needs- small bore copper cannon. The elbows of the cannon would be two tee's, the lower tee connected directly to the chamber is the piston. The upper Tee is the same diameter of the chamber, leaning towards 3/4". Inside the T will be a wooden dowel designed to be very snug inside the Tee. The dowel will be bored out to about 1/2"-the outer diameter of the barrel. Another hole drilled to allow airflow from the chamber into the Tee. A small section of pipe, about four to six inches long will be free floating inside the dowel, this is the bolt. When the bolt is fully forward -or closed- a hole drilled through the pipe will line up with the hole in the dowel and the Tee. This is to allow the airflow from chamber to barrel.

With the bolt all the way back, a section will be cut away to allow loading from the rear of the Tee, pushing the bolt forward will slid the projectile through the Tee and into the main section of the barrel. Now provided the bolt assembly seals, all should work fine and dandy as a normal chamber-sealing over-under.

Comments, critiques?

Rough Sketch-Apologies for the greyish area.

I'll apologize ahead of time for no sketches uploaded, my scanner hates me, and Google Sketch-up has been beating me over the head for a week now, so no 3-D models either.

Essentially it would be an over under, chamber-sealing piston -QEV, not sure which is best suited for my needs- small bore copper cannon. The elbows of the cannon would be two tee's, the lower tee connected directly to the chamber is the piston. The upper Tee is the same diameter of the chamber, leaning towards 3/4". Inside the T will be a wooden dowel designed to be very snug inside the Tee. The dowel will be bored out to about 1/2"-the outer diameter of the barrel. Another hole drilled to allow airflow from the chamber into the Tee. A small section of pipe, about four to six inches long will be free floating inside the dowel, this is the bolt. When the bolt is fully forward -or closed- a hole drilled through the pipe will line up with the hole in the dowel and the Tee. This is to allow the airflow from chamber to barrel.

With the bolt all the way back, a section will be cut away to allow loading from the rear of the Tee, pushing the bolt forward will slid the projectile through the Tee and into the main section of the barrel. Now provided the bolt assembly seals, all should work fine and dandy as a normal chamber-sealing over-under.

Comments, critiques?

Rough Sketch-Apologies for the greyish area.