to start i sliced off the steel retaining ring with a dremel

once that was sliced off and removed

the slide collar came right off revaling the 3 steel balls and the spring

then i put the rest of the quick connect in my vise and started wrenching on it dont worry about damaging the end were the slide collar came from

when the other end finally opened from me wrenching on it a spring a piston and o-ring came out the piston was pointed on one side and cylindrical with holes drilled in it on the other side

i reversed the piston so the sharp side pointed toward the end were u put the male connect

then i put the assembly in the vice and cut off the majority of the side that had the slide collar i did this because the neck on the co2 powerlet wasnt long enough th reach the o -ring and the pointy end of the piston

then i cut a length of brass rod from an old lantern sparker so as not allow the piston to travel to far back wards

i screwed a male female quick conect into the female 2x quick connect

then i put a male quick connect into the female one that was still stock

finished product

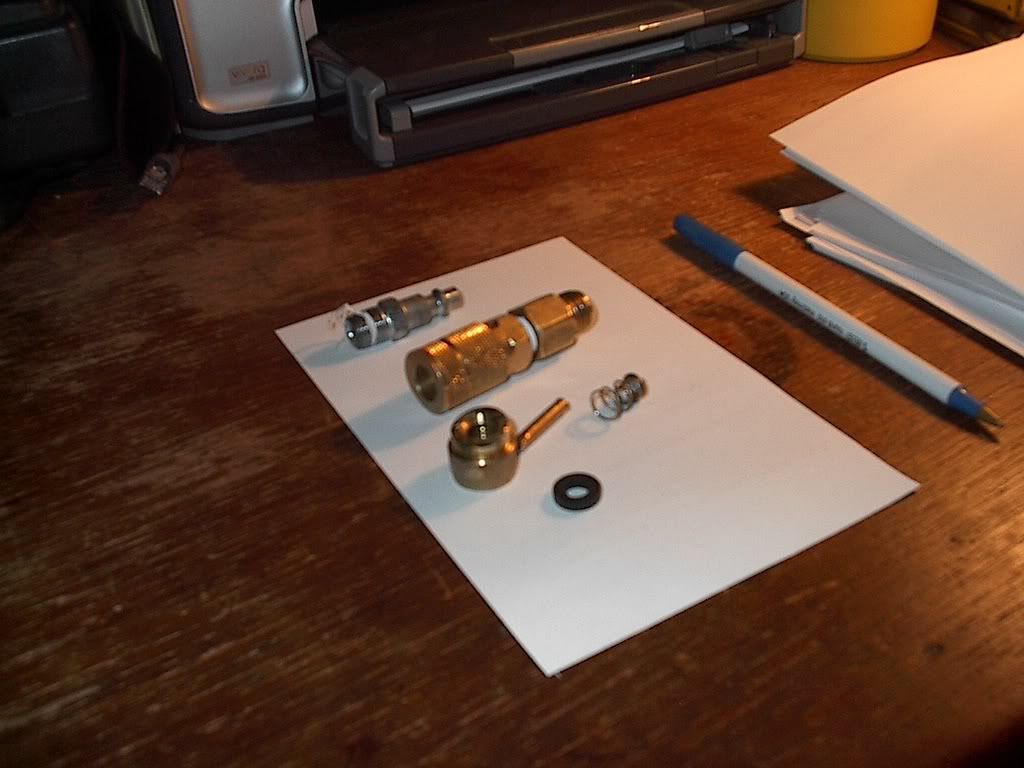

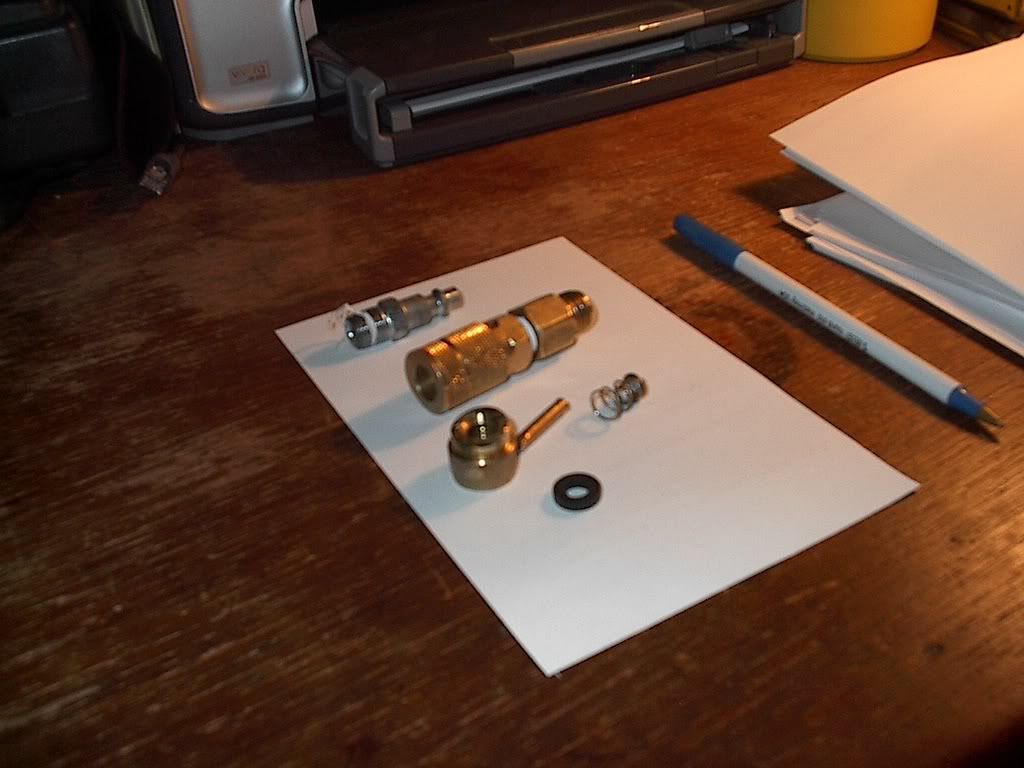

all the components needed

looking in {note spring, piston and rod removed}

the internals

i pressured tested the setup and it is good

the male quick connect can be threaded into the spudgun

u can then take the adaptor off and transfere it from spudgun to spudgun