saefroch wrote:Rifled barrels have been discussed many times before, such as

this thread, the general consensus is that most spudguns do not have the ability to make use of rifling, in that they cannot accelerate a projectile fast enough to compress it into the rifling and make it spin, and make any meaningful use of the rifling.

This is a simple matter of projectile design. If you're using PVC, you'd obviously be using potatoes with a rifled barrel, which are very capable of riding along rifling grooves. If you're using a harder metal, lead can be used, it's just a matter of how much pressure your gun operates at. Projectiles like pellets (which reduce the material being gripped by the rifling to two narrow areas front and back) and minié balls (which have a skirt that expands when fired to engage the rifling) can be used along with lower pressure guns.

@hyperspaz: what you're planning to do is pull what's called a "button" through your barrel. If you look at al-xg's

thread, he does the same basic thing, but grinds his button from a bolt head.

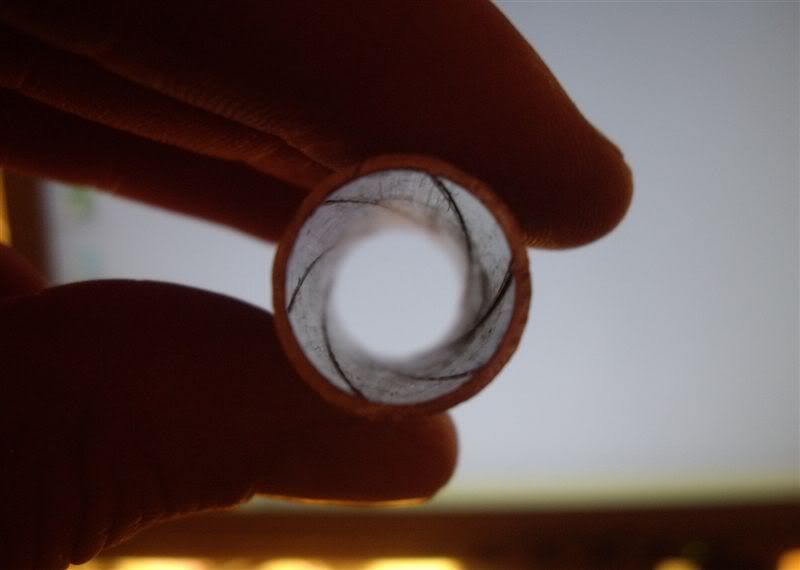

Buttons will work for shallow, thin grooves like seen in al-xg's photo. For deeper or wider grooves, a button becomes much harder to pull through a barrel, which will require some ingenuity and lubrication.... something like a ratchet strap and lithium grease at best, or, if you're getting really ridiculous, a full length puller jig made from angle iron which allows attachment of a hydraulic jack at various points.

That drill bit may work if you are able to size it just so. Given that it's a woodworking bit, I doubt it comes in a vast selection of sizes, but there are some decent match-ups, like a 7/8" bit in 3/4" SCH-40 pipe (0.81" ID typically), or (for really shallow grooves), an 11/16" bit in 1/2" SCH-40 pipe (5/8" ID typically).