Page 1 of 1

Silencer (diagrams)

Posted: Wed Aug 09, 2006 7:39 am

by LucyInTheSky

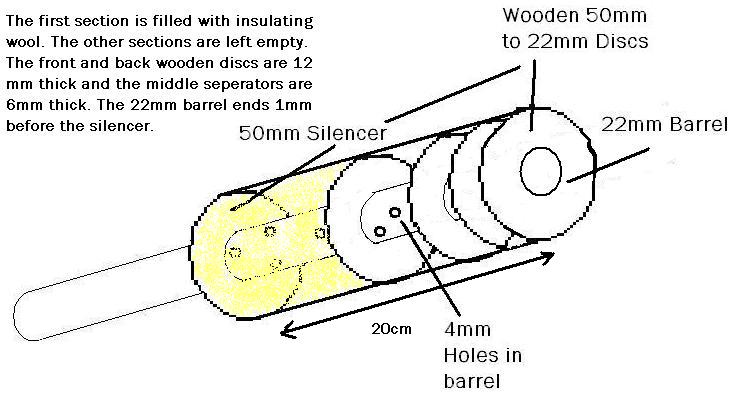

I have come up with a few designs for a silencer for my gun (I live in UK so dont say they are illegal please). I have already go the 50mm silencer and wooden discs that act as bushings (but the silencer is PVC and barrel Copper), but I dont know how to go about the rest of the silencer to make it most effective. Also I am very sorry for not resizeing the pics as I forgot befor I uploaded them and uploading took quite a while.

The design shown here will work by letting the air fill that space then coming out of the barrel at a lower pressure at 145psi it would come out at 80psi but with the silencer it would come out at 50psi.

http://i59.photobucket.com/albums/g294/ ... 6/orig.jpg

This is based on a real silencer I think.

http://i59.photobucket.com/albums/g294/ ... gdiscs.jpg

This just kinda lets all the air out.

http://i59.photobucket.com/albums/g294/ ... ighole.jpg

This I dont really know how works but I saw it on advancedspuds.com

http://i59.photobucket.com/albums/g294/ ... lewool.jpg

Which one do you think would work the best?

Posted: Wed Aug 09, 2006 7:41 am

by Dom

Id say probably the last one... But if it gets in your barrel there's some risk there.

Posted: Wed Aug 09, 2006 8:11 am

by Nereth

the last would be pretty good, yeah...

However, the first one is easier, and could work just as well. if it were big enough.

Put your standard barrel length on there, then put a say... 5 inch silencer over that (big holes so the gases vent inr eal fast), and another 5 inches barrel at the end. Make the silencer part something like 3 times the diameter of your pipe, and then do something really awesome: extend it over the pipe, towards your face (not the muzzle end) with an open end, so it literally shoots gas backwards. Extend it back some 10 inches maybey more if theres room. Before it opens into the air, it may help to restrict the flow a bit, im not sure.

Thatl allow the air to expand hugely before the muzzle opens, which should help greatly you might want to put some iron wool or sometihng to act as baffles, you might want to reduce the flow, and im really not sure this will work at all. Im banking on the air decompressing and releasing slowly before the projectile leaves the barrel. It will also act as a muzzle break, if your projectile doesnt leave too quickly.

Posted: Wed Aug 09, 2006 8:13 am

by FiveseveN

The one with multiple chambers (with disks) should work better in theory. For better performance, you have to space the discs in a certain manner: the 1st chamber (the one closest to the breech) should be about half the silencer's total volume, the next (towards the muzzle) should be about half the remaining volume, and the next half of the rest.

The total volume of your silencer must be big enough to trap most or all of the exiting gases. If it's a pneumatic, you can calculate this value. In a combustion, it's a bit tricky, but it's usually no more than the volume of the barrel, in a well-constructed cannon (ideal C/B ratio).

Posted: Wed Aug 09, 2006 11:37 am

by LucyInTheSky

@ FiveseveN would you please explain how to calculate the size of my silencer?

Its a pneumatic, chamber= 428ml barrel=360ml silencer=50mm x 200mm

But I can change the size of the barrel and silencer.

Posted: Wed Aug 09, 2006 11:45 am

by DonTheLegend

I've made the last type on a combustion gun and it is effective. The second design would probably be the best if you can make it work though, because when you use wadding to fill the space between the barrel and outer shell of the silencer, after use, the gases will compress the wadding making it less effective and you will have to replace it.

Posted: Thu Aug 10, 2006 7:33 am

by LucyInTheSky

I have decided to use this design for my silencer so I will let you know how it goes, please tell me if you see anything wrong with it. It is based on how an actual firearm silencer works.

EDIT: I was thinking should I drill holes in the first chmaber?

Posted: Thu Aug 10, 2006 9:55 am

by FiveseveN

That's pretty much what I describes. Looks good. You shouldn't drill holes in the chambers, if the total volume is big enough.

Posted: Thu Aug 10, 2006 1:51 pm

by LucyInTheSky

The volume of the silencer is the same as the barrel. Is that big enough?

Posted: Fri Aug 11, 2006 3:46 am

by rna_duelers

In reall silencers the volume of the silencer is upto 20times the volume.No doubt you have seen silencers on a hand gun they are quite large for there size.But i would be interested in how well it works and i might use one on my gun.

Posted: Fri Aug 11, 2006 5:41 am

by LucyInTheSky

Well today I am going to make 3-4 different silencer designs and I will post pics tonight with results.

Unfortunatly I havent go any thing to mesure sound so I will just have to guess.

Posted: Fri Aug 11, 2006 3:41 pm

by boilingleadbath

rna, we've been over this before... REAL GUNS OPERATE AT 10,000-50,000 (roughly) PSI, AND SPUDGUNS OPERATE AT 50-100 PSI.

Direct comparisons it silencer:barrel volume ratios are pretty damn stupid.

Posted: Fri Aug 11, 2006 3:51 pm

by LucyInTheSky

I decided to go with not putting the barrel through the silencer and just slipping it over the end, then I added 4 baffels inside the silencer with bores of 25mm (the barrel is 22mm). This is most silamler to a real silencer exept with out the extream volume which obviously (as BLB pionted out) is only because of the extream pressures of a firearm.

I tested it out before (without ammo, so I dont know if it will smack off the baffels and break the whole thing) and it seemed to muffel the sound from a CRACK!!! to a GMMMFFFFF....

Posted: Sun Dec 10, 2006 8:54 pm

by Hayseed_Andrew

Ideally, It should sound wumpfh, or phut, but GMMMFFFFF is a good start. If I were you, I'd make the silencer really big, exactly like everyone else says.