Page 1 of 1

Electromagnetic Piston Valve

Posted: Fri Jun 01, 2007 12:16 pm

by squeaks

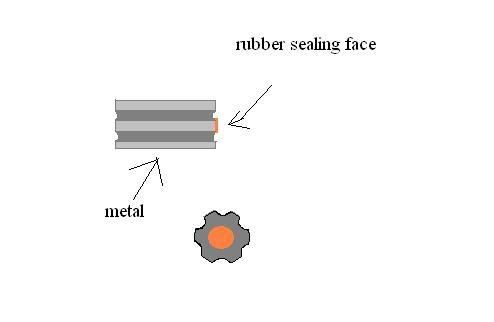

Here's the idea. An electromagnet would be installed around the exhaust pipe that the piston seals against. A switch would turn it on sealing the piston. Once the chamber was filled, the switch would be flipped again, firing the gun.

Pros

High Efficiency

Switch Opperated

Looks Cool

Cons

Heavy Piston

O-rings Needed

Powerful Electromagnet Required

Batteries Not Included

Posted: Fri Jun 01, 2007 12:28 pm

by Fat Pants

Clever idea, i reckon it's work quite well, but the cons do obviously bring it back.

Can only try i guess.

Posted: Fri Jun 01, 2007 12:54 pm

by FeLeX

My question is how much psi is the magnet able to hold. Is it possible to buy/make an electromagnet that can hold decent amount of pressure and not spend a fortune on it.

If its any where to at least 40 then if could be pretty good design for small coaxial gun. I really like the idea though, but it seems too good to be true.

Posted: Fri Jun 01, 2007 1:51 pm

by clide

The Zooka pitching machine uses an electromagnetic valve.

http://www.google.com/patents?vid=USPAT6807959

Your design looks like it would work pretty well, but I would try to make sure that the piston and the electromagnet are touching or very close when the valve is closed to minimize the strength you need for the magnet.

If you were running it off a battery then you would also need to be concerned about accidental firings when the battery got weak.

Posted: Fri Jun 01, 2007 1:52 pm

by pyromanic13

If you made a coaxial with a metal barrel and a neo-magnet in the piston then it'd be like a reuseable burst disk....

btw I think i'd be impracticle to to have a electromagnet that can hold back 100 psi.

Posted: Fri Jun 01, 2007 1:55 pm

by squeaks

First thing is that you will have to get a small surface area that air is pushing on the piston, say a 2" valve in a 2.5" tee. Next, all you need is a good enough magnet, as you said, which isn't difficult to construct. All you need is a core, some coiled wire, and a battery. More batteries wired together will create a stronger magnetic field. I also had another idea. You could construct a second electromagnet underneath the bumper that would be switched on when the other would be switched off.

Also, the piston could be partially made with metal and the rest with a lightweight piston material such as foam. This way the pistons weight would be greatly reduced.

Posted: Fri Jun 01, 2007 2:34 pm

by VH_man

just use a spring catch mechanism. someone did that here a while a go with a syringe. from what i remember he sasid it was hella powerful, beacuse of the fast actuation time. i dont reccomend the electromagnet, its prone to failure. just stick with the good old sear and catch.

also, you could get some earth magnets and make the piston want to stick to the sealing face, and when the gun hit a certain pressure BOOOMMM and then the piston would close again. might be useful for hybrids.........

Posted: Fri Jun 01, 2007 4:19 pm

by squeaks

What would be prone to failure with an electromagnet? The only thing that would turn it off would be disconnecting the power. A four year old could make an electromagnet. The only difficult thing with this idea is that it would require o-rings on the piston. The electromagnet could just be a metal sleeve wrapped in wire that would fit over the exhaust pipe. Just epoxy it in place and connect the wire to a battery box - I say box because you'll need several good batteries to get the required pull.

Posted: Fri Jun 01, 2007 9:18 pm

by lukemc

what if the piston had no o rings and the electro magnet was behind it so it slides forward and gets "sucked" to the barrel becuase of the pressure differential. then when the electro magnet behind it is turned on the piston moves back and the air slides past the piston (because of the lack of orings)

Posted: Sat Jun 02, 2007 4:28 pm

by squeaks

That would require a much more powerful electromagnet and would decrease performance. The main benefit with this kind of valve would be the lack of a need to vent the pilot. In this way there is no pressure that is fighting the movement of the piston.

Posted: Sat Jun 02, 2007 4:52 pm

by lukemc

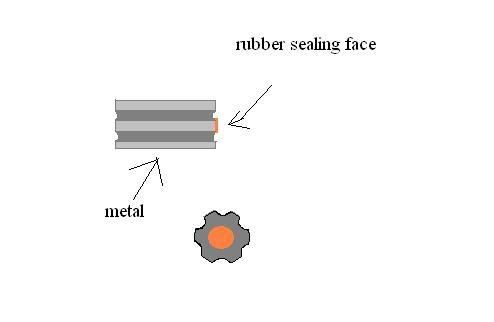

if you made the piston like this there would be almost no air resistance when it moves so the electromagnet might not need to be as strong

Posted: Sat Jun 02, 2007 4:57 pm

by jrrdw

Mag Locks, fire code for all airports emergancy exits when the fire alarm goes off. 2,000 pounds per square inch holding power, you would have to ram the door with a truck to break the field, but turn the electric off and no resistance what so ever. So in closing, magnet activated piston is a great idea. I wanted to use a solinoid operated piston but solinoids, (strong fast ones) are really pricey, and use lots of power!

Posted: Sat Jun 02, 2007 4:58 pm

by VH_man

yeah, like i said, someone on this fourum did this with a catch and sear. it would be much safer and more reliable than what you are describing.

Posted: Sat Jun 02, 2007 5:01 pm

by lukemc

VH_man wrote:yeah, like i said, someone on this fourum did this with a catch and sear....

? what is a catch and sear?

Posted: Sat Jun 02, 2007 5:05 pm

by jrrdw

VH_man wrote:yeah, like i said, someone on this fourum did this with a catch and sear. it would be much safer and more reliable than what you are describing.

Yes, i seen that, it was a contest entry. Was it Clides? I think so.