Detonation gun

Sounds an interesting prospect.

As we haven't reached the 5 per page limit on "meaty chunks", I must also say it will need it's own safety precautions, before it resembles the average Mythbusters episode. Put it this way, I wouldn't stand next to it.

I have concerns about the electrolysis of the water in the chamber, because the mix will be affected by the air already within it, and that will likely affect the flame speeds.

It might be necessary to purge the chamber with an inert gas (nitrogen, or helium - helium would be better) first to get a reliable mix.

The other thing you REALLY want when going for a detonation event is turbulence in the chamber, and your chamber is clearly getting towards the size that chamber fans can't fit in it. I have seen 17mm computer fans that would fit, but they wouldn't stand up to detonation well.

I can't think of any options for pre-mixing other than some how using a magnetic transmission to drive a mixer within the chamber, but maybe someone else knows better. You could have some "baffles" or other restrictions that would help create turbulence after ignition, but I don't know how well that would work.

As we haven't reached the 5 per page limit on "meaty chunks", I must also say it will need it's own safety precautions, before it resembles the average Mythbusters episode. Put it this way, I wouldn't stand next to it.

I have concerns about the electrolysis of the water in the chamber, because the mix will be affected by the air already within it, and that will likely affect the flame speeds.

It might be necessary to purge the chamber with an inert gas (nitrogen, or helium - helium would be better) first to get a reliable mix.

The other thing you REALLY want when going for a detonation event is turbulence in the chamber, and your chamber is clearly getting towards the size that chamber fans can't fit in it. I have seen 17mm computer fans that would fit, but they wouldn't stand up to detonation well.

I can't think of any options for pre-mixing other than some how using a magnetic transmission to drive a mixer within the chamber, but maybe someone else knows better. You could have some "baffles" or other restrictions that would help create turbulence after ignition, but I don't know how well that would work.

Does that thing kinda look like a big cat to you?

- boilingleadbath

- Staff Sergeant 2

- Posts: 1635

- Joined: Sat Mar 12, 2005 10:35 pm

- Location: Pennsylvania, USA

Baffles? That's a tad complex; just drop a compression spring into the chamber and make a schelkin spiral.

-

SpudBlaster15

- First Sergeant 3

- Posts: 2400

- Joined: Wed Oct 18, 2006 11:12 pm

- Has thanked: 2 times

- Been thanked: 10 times

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras nec placerat erat. Vivamus dapibus egestas nunc, at eleifend neque. Suspendisse potenti. Sed dictum lacus eu nisl pretium vehicula. Ut faucibus hendrerit nisi. Integer ultricies orci eu ultrices malesuada. Fusce id mauris risus. Suspendisse finibus ligula et nisl rutrum efficitur. Vestibulum posuere erat pellentesque ornare venenatis. Integer commodo fermentum tortor in pharetra. Proin scelerisque consectetur posuere. Vestibulum molestie augue ac nibh feugiat scelerisque. Sed aliquet a nunc in mattis.

Last edited by SpudBlaster15 on Wed Jul 14, 2021 6:01 pm, edited 1 time in total.

SB15: Thank you for the most informative reply yet. I tried to download GasEQ, but couldn't get it to work.

I already have researched the aluminum alloys a bit, which was the reason for my initial choice of 2024. An ABS inner sleeve would be nice, the only problem is that I would then need to make the outer aluminum have a larger OD, meaning more $$$. But this wouldn't be cheap anyway, and I would like the chamber to survive for as long as possible.

As for purging the chamber with an inert gas beforehand: I do have nitrogen, and will likely get helium soon, but properly purging the chamber would require an inlet valve, as well as a check valve to allow the air to escape. That means two more valves that would be subjected to repeated detonation, which they may not like very much. Any solutions on this problem would be appreciated.

@BLB: Care to elaborate on the Schelkin spiral idea? What exactly is it?

I already have researched the aluminum alloys a bit, which was the reason for my initial choice of 2024. An ABS inner sleeve would be nice, the only problem is that I would then need to make the outer aluminum have a larger OD, meaning more $$$. But this wouldn't be cheap anyway, and I would like the chamber to survive for as long as possible.

As for purging the chamber with an inert gas beforehand: I do have nitrogen, and will likely get helium soon, but properly purging the chamber would require an inlet valve, as well as a check valve to allow the air to escape. That means two more valves that would be subjected to repeated detonation, which they may not like very much. Any solutions on this problem would be appreciated.

@BLB: Care to elaborate on the Schelkin spiral idea? What exactly is it?

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

- mark.f

- Sergeant Major 4

- Posts: 3643

- Joined: Sat May 06, 2006 11:18 am

- Location: The Big Steezy

- Has thanked: 58 times

- Been thanked: 62 times

- Contact:

My only question/suggestion, (it looks like you have the general process pretty downpat), would be... why are you using a 75 buck aluminum union? You can get steel unions rated to 3,000 PSI for much cheaper.

Also, if you expect it to explode... why not build a good remote ignition system, with a blast shield somewhere as well, and start off with cheaper materials? I know I'm probably going to be flamed for saying this, but I wouldn't invest such expensive and custom materials into something I suspected could explode. I would start off with cheaper materials, (such as SCH-80/SCH-160 pipe and fittings), and see where I got first, of course, being safe about it as well.

I would never suggest the above to a newer member, but I think you're mature enough to take the proper safety precautions for such actions.

Also, if you expect it to explode... why not build a good remote ignition system, with a blast shield somewhere as well, and start off with cheaper materials? I know I'm probably going to be flamed for saying this, but I wouldn't invest such expensive and custom materials into something I suspected could explode. I would start off with cheaper materials, (such as SCH-80/SCH-160 pipe and fittings), and see where I got first, of course, being safe about it as well.

I would never suggest the above to a newer member, but I think you're mature enough to take the proper safety precautions for such actions.

The whole reason for not using steel is that it doesn't absorb shock as well as aluminum or brass, and it would stand a higher chance of being fatigued and broken by repeated detonations. Thick enough steel would survive one detonation easily, but subsequent ones could fatigue it to the point of failure. And SCH 80 or 160 steel fittings are so expensive, I might as well do it right the first time.

I don't expect that the chamber itself would ever explode, only some of the fittings connected to it. Not the union though, it should survive quite well. It's the other fittings, for purging and such, that I would worry about.

And remote detonation and shrapnel shielding will of course be built into the design, as I believe I mentioned in one of my earlier posts.

I don't expect that the chamber itself would ever explode, only some of the fittings connected to it. Not the union though, it should survive quite well. It's the other fittings, for purging and such, that I would worry about.

And remote detonation and shrapnel shielding will of course be built into the design, as I believe I mentioned in one of my earlier posts.

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

Well, firstly, you'll need to switch those valves over. The check valve would need to be the input.DYI wrote:As for purging the chamber with an inert gas beforehand: I do have nitrogen, and will likely get helium soon, but properly purging the chamber would require an inlet valve, as well as a check valve to allow the air to escape. That means two more valves that would be subjected to repeated detonation, which they may not like very much. Any solutions on this problem would be appreciated.

However, for a idea, although it would need work to become a solution, how about this? You have some kind of an aluminium "piston" within the chamber. This is either sprung, or has pressure behind it, so that it's pushed forwards and the chamber has little in it other than water when you begin. This piston is then pushed back to a stop by the pressure created by the electrolysis.

That obviously conflicts with other things, but I can't come up with everything.

Does that thing kinda look like a big cat to you?

I am certainly not an expert on this issue, but I have found a PDF that is specifically about DDT. It also deals with Schelkin spirals, and contains a diagram of a DDT vessel.

http://www.innssi.com/images/pde03/AIAA-2005-1343.pdf

http://www.innssi.com/images/pde03/AIAA-2005-1343.pdf

“He who controls the present, controls the past. He who controls the past, controls the future.”

-George Orwell

-George Orwell

Couldn't you purge your gun with water, rather than gas? It's obviously harder to do with bigger guns, but a smaller one it's feasable.

If you fill your chamber with water and then put the whole thing under water in a container, barrel down, you can then fill it with your gases, displacing your water down the barrel.

There's a lot of fiddling round under water there and water and electricity don't mix well, but...

If you fill your chamber with water and then put the whole thing under water in a container, barrel down, you can then fill it with your gases, displacing your water down the barrel.

There's a lot of fiddling round under water there and water and electricity don't mix well, but...

Actually, water and electricity mix VERY well, just like cigarettes and explosive gas do.SPG wrote:There's a lot of fiddling round under water there and water and electricity don't mix well, but...

Does that thing kinda look like a big cat to you?

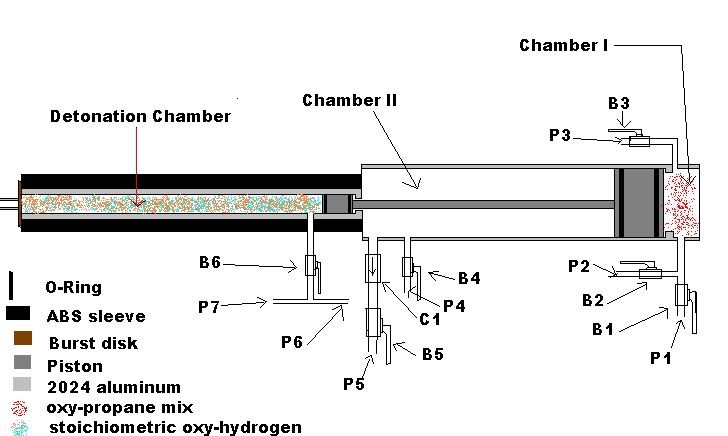

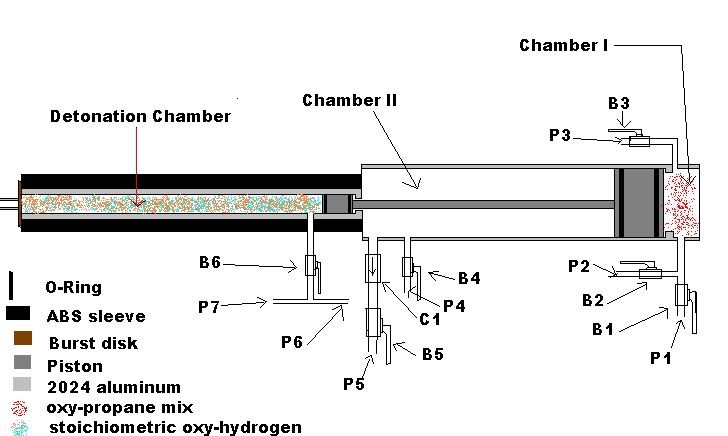

I just came up with a new idea for this. It's shear genius really, and solves almost all of the existing problems at once. It involves no holes or valves of any type in the detonation vessel. In fact, no tapped holes or valves are ever exposed to pressures in excess of 120 psig, while the firing pressure after DDT will be even higher than the pressure from the original plan.

Instead of igniting a pre-compressed mix with a spark plug, I could use a gas-ram type idea, combined with some of the principles of a light gas gun and some of the principles of a diesel engine. The result would be something capable of achieving completely insane muzzle velocities, with few parts which can be weakened or destroyed. The diagram shown is not to scale, as the entire apparatus would be over 20' long in reality.

Firing sequence (not recommended for those with a short attention span)

1. Ready state: B1, B2, B3, B4, B5, B6 are closed, piston is fully back against stops, all chambers are at atmostpheric pressure.

2. B6 is opened, det. chamber is purged with helium

3. Burst disk is placed

4. Det. chamber is filled to ~30 psi with stoichiometric O2/H2 mix, B6 is closed

5. B2 and B3 are opened, helium is injected through P2 to purge Chamber I.

6. B2 and B3 are closed, B1 is opened. Oxy/propane mix is injected through P1.

7. P1 is closed, B5 is opened.

8. Oxy/propane is ignited. Piston is pushed forward, shock heating and compressing O2/H2 mix until it autoignites.

9. O2/H2 flame front accelerates and transitions to detonation, likely in less than 12" due to greatly increased pressure and temperature.

10. Pressure in detonation chamber rises in less than 1ms to several kpsi. Burst disk ruptures, propelling projectile out barrel at >Mach 4.

11. Piston comes to a rest (rather violently) at front of stroke. B4 is opened, B5 is closed, B3 is opened, and helium is injected through P4 to return piston to rest position.

12. B5 is opened, then closed, det. and I chambers are purged with helium, and system is returned to rest state.

I would like to know, assuming that the det. chamber is 1" diameter, and injected fuel is approximately 30 psi, how far the mix will have to be shock compressed before it reaches it's autoignition point, and, at this temp. and pressure, how long its detonation run up distance will be, what the SOS will be in the post-detonation millisecond, and what the velocity of the detonation wave will be.

Instead of igniting a pre-compressed mix with a spark plug, I could use a gas-ram type idea, combined with some of the principles of a light gas gun and some of the principles of a diesel engine. The result would be something capable of achieving completely insane muzzle velocities, with few parts which can be weakened or destroyed. The diagram shown is not to scale, as the entire apparatus would be over 20' long in reality.

Firing sequence (not recommended for those with a short attention span)

1. Ready state: B1, B2, B3, B4, B5, B6 are closed, piston is fully back against stops, all chambers are at atmostpheric pressure.

2. B6 is opened, det. chamber is purged with helium

3. Burst disk is placed

4. Det. chamber is filled to ~30 psi with stoichiometric O2/H2 mix, B6 is closed

5. B2 and B3 are opened, helium is injected through P2 to purge Chamber I.

6. B2 and B3 are closed, B1 is opened. Oxy/propane mix is injected through P1.

7. P1 is closed, B5 is opened.

8. Oxy/propane is ignited. Piston is pushed forward, shock heating and compressing O2/H2 mix until it autoignites.

9. O2/H2 flame front accelerates and transitions to detonation, likely in less than 12" due to greatly increased pressure and temperature.

10. Pressure in detonation chamber rises in less than 1ms to several kpsi. Burst disk ruptures, propelling projectile out barrel at >Mach 4.

11. Piston comes to a rest (rather violently) at front of stroke. B4 is opened, B5 is closed, B3 is opened, and helium is injected through P4 to return piston to rest position.

12. B5 is opened, then closed, det. and I chambers are purged with helium, and system is returned to rest state.

I would like to know, assuming that the det. chamber is 1" diameter, and injected fuel is approximately 30 psi, how far the mix will have to be shock compressed before it reaches it's autoignition point, and, at this temp. and pressure, how long its detonation run up distance will be, what the SOS will be in the post-detonation millisecond, and what the velocity of the detonation wave will be.

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

It sounds like it would work. A better drawing would help me understand it more but i got the concept, not to doubt your art skills  .

.

you forgot to add a B5, there are just 2 B6s from what i see.

Well i dont think many people will know the answer to this so i suggest a prototype of some sort. You probably can find the pressure and temperature the will autoignite at but for the wave produced you may need to do tests for that.

you forgot to add a B5, there are just 2 B6s from what i see.

Well i dont think many people will know the answer to this so i suggest a prototype of some sort. You probably can find the pressure and temperature the will autoignite at but for the wave produced you may need to do tests for that.

4SPC, My 4" piston 3" porting cannon

Memo:

Fix up copper cannon

Fix up 4SPC

Start Stirrup pump

Start Toolies piston bazooka

Memo:

Fix up copper cannon

Fix up 4SPC

Start Stirrup pump

Start Toolies piston bazooka

- Fnord

- First Sergeant 2

- Posts: 2239

- Joined: Tue Feb 13, 2007 9:20 pm

- Location: Pripyat

- Been thanked: 1 time

- Contact:

Autoignition temp of hydrogen: 571 °C (1060 °F)

Think you can do that? It'll probably be a compression ratio of like 30:1 or something.

Edit: That number was taken from the wiki, but I believe it is for a hydrogen/air mix, not pure oxygen. Wouldn't the ignition point drop considerably with 5x more oxygen than air?

Think you can do that? It'll probably be a compression ratio of like 30:1 or something.

Edit: That number was taken from the wiki, but I believe it is for a hydrogen/air mix, not pure oxygen. Wouldn't the ignition point drop considerably with 5x more oxygen than air?