Boom! The classic potato gun harnesses the combustion of flammable vapor. Show us your combustion spud gun and discuss fuels, ratios, safety, ignition systems, tools, and more.

-

Fnord

- First Sergeant 2

- Posts: 2239

- Joined: Tue Feb 13, 2007 9:20 pm

- Location: Pripyat

- Been thanked: 1 time

-

Contact:

Sun Feb 08, 2009 7:30 pm

Not to hijack the topic, but have you built a coaxial combustion?

No. Do you have a problem with that?

________

What I am suggesting, metallover, is something like this. Easy to build, but requires some sheet pvc (or alternatively a lot of epoxy). You have plenty of room for spark gaps, and you can even put one or two smaller fans below the barrel.

You can also keep your breech loading without using a wye, which are not pressure rated by the way.

-

Attachments

-

- This is the same way my first combustion was constructed, the only difference was I didn't push the barrel in that far.

- fsghdsr.GIF (2.25 KiB) Viewed 2681 times

-

Combustion Monkey

- Specialist

- Posts: 153

- Joined: Sun Jan 11, 2009 3:01 pm

Sun Feb 08, 2009 7:55 pm

_Fnord wrote:Not to hijack the topic, but have you built a coaxial combustion?

No. Do you have a problem with that?.

Sorry for the sharp comment Fnord, it was late and I must have been a bit testy.

As far as your coax setup, I like the idea. How difficult is it to get the barrel in straight? Also, how large a fan or fans would fit under the barrel, assuming standard pc fans?

-

metallover

- Private 4

- Posts: 95

- Joined: Fri Apr 18, 2008 12:20 pm

-

Combustion Monkey

- Specialist

- Posts: 153

- Joined: Sun Jan 11, 2009 3:01 pm

Sun Feb 08, 2009 8:04 pm

How long did you make your barrel and have you figured your CB ratios, coax verses standard? Just curious to see the numbers.

EDIT: I just noticed, are your camlocks big enough to allow your barrel to pass through them? They look like 2 inch.The camlocks that are available here are from a different manufacturer but I had to use a 3 inch camlock to get my barrel to pass through it.

-

metallover

- Private 4

- Posts: 95

- Joined: Fri Apr 18, 2008 12:20 pm

Sun Feb 08, 2009 8:13 pm

Oh jeez... Hmm the chamber is 10" of 4"pvc. That's about 2057cc

The barrel is 7' of 1.5" which is 2704cc

The calculated C:B ratio non coaxial is .751:1. If I did a coaxial the C:B ratio would probably not change too much. I would have it only part way in, maybe 6". That would take around 200cc's from the chamber. It would change to about .676.

I wanted my C:B ratios to be pretty low because I shoot spuds and the C:B ratio doesn't matter as much. Also because I live in town and I do half of my shooting there,so I'd like it to be quieter.

In a nutshell-

Regular - .751:1 C:B

Coaxial - .676:1 C:B (half coaxial - 60% length of chamber has the barrel in it)

The camlocks are 2". I had to bore the crap out of the peice that goes on the barrel. The one that attaches to the chamber took some boring, but not too much. The camlock systme works flawlessly.

-

Fnord

- First Sergeant 2

- Posts: 2239

- Joined: Tue Feb 13, 2007 9:20 pm

- Location: Pripyat

- Been thanked: 1 time

-

Contact:

Sun Feb 08, 2009 8:22 pm

How difficult is it to get the barrel in straight? Also, how large a fan or fans would fit under the barrel, assuming standard pc fans?

1)I'd recommend using a vice and clamps to get the barrel straight when the glue is drying. If the hole you drilled is nice and clean it'll line itself up.

2)With a 4" chamber and 1.5" barrel you'll have a bit over 2 inches. You can easily get a 50mm cpu fan in there.

You could potentially get 80mm fans in if you mounted them horizontally. A bit trickier but it'll mix the fuel just as good.

(Though I see he ordered parts already. Oh well it'll turn out good anyway.)

-

Combustion Monkey

- Specialist

- Posts: 153

- Joined: Sun Jan 11, 2009 3:01 pm

Sun Feb 08, 2009 8:35 pm

Very nice work so far! So instead of a true breechloader, your going to remove the barrel and load spuds there? That should work great for your length. I would do it myself, but the size of the barrels makes it clumsy. I have a gun in the works that will have all the barrel in the chamber wich will be removed for loading.

-

metallover

- Private 4

- Posts: 95

- Joined: Fri Apr 18, 2008 12:20 pm

Sun Feb 08, 2009 8:44 pm

What do you mean by true breech loader? I thought this was a true breech loader...

The breech loading system will only work for 1.5" barrels. I can change to a different barrel by making it accept a male 4" thread or female 2" thread.[tennis ball]

-

metallover

- Private 4

- Posts: 95

- Joined: Fri Apr 18, 2008 12:20 pm

Sun Feb 08, 2009 9:11 pm

A question came up just now. To shoot a tennis ball, 2.5" pvc works. A baseball is 2.5" in diameter. Could I shove it in a 2.5" barrel or would I need to go bigger with a saboe(<-spelling) or wadding?

-

Combustion Monkey

- Specialist

- Posts: 153

- Joined: Sun Jan 11, 2009 3:01 pm

Mon Feb 09, 2009 4:32 am

It's just the way I think about things. It is a breechloader, in my little world a "true" breechloader is anything that can be loaded from the breach with the barrel still attached, thats all. The removable barrel design needs a cool name like "Take Down Breechloader" to differentiate it in my way of thinking.

-

metallover

- Private 4

- Posts: 95

- Joined: Fri Apr 18, 2008 12:20 pm

Wed Feb 11, 2009 6:25 pm

Thanks fora ll your help so far guys. I have still not decided if I will make it a coax or not...

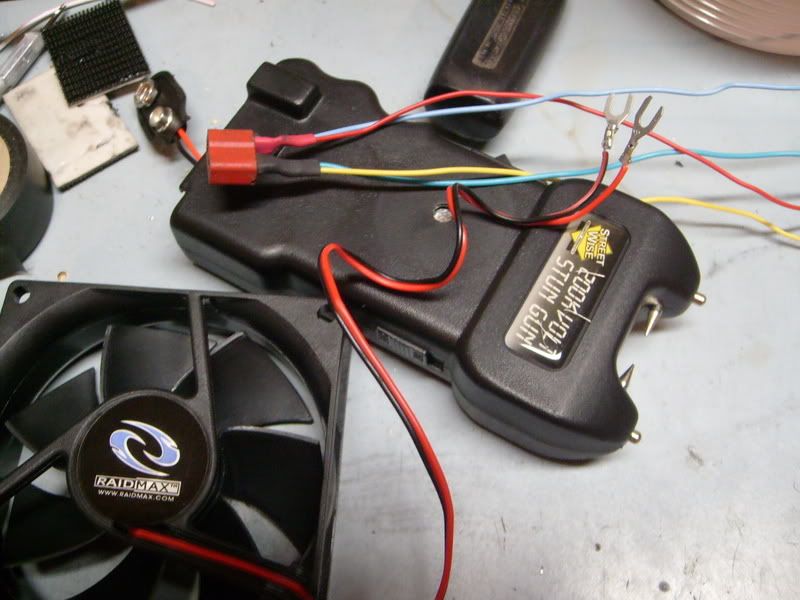

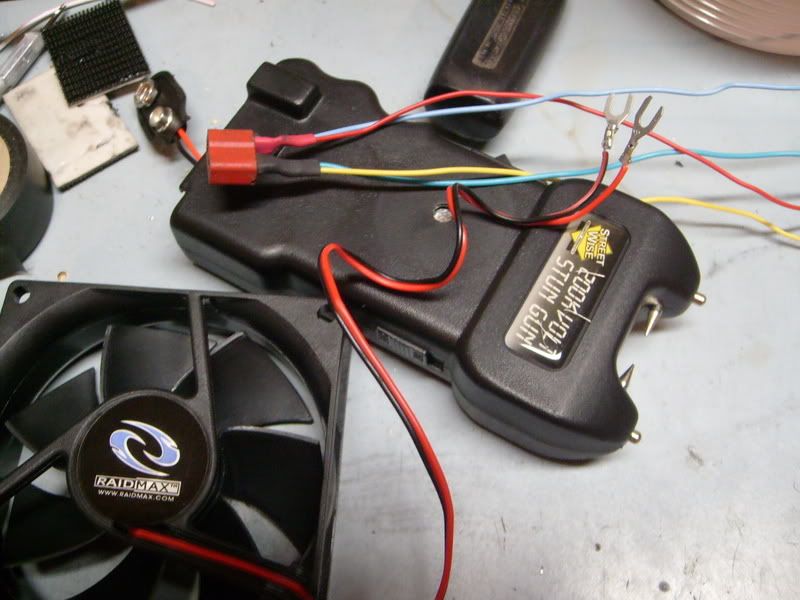

I got about 20 bucks of stuff from ebay today.

-The stungun is pretty cool. I need to remove the alarm as it's really dang loud... The one problem is that I cant figure out how to open it up. I can't see any screws on the outside or inside the battery case...

-The chamber fan looks like it'll work great. I crimped and soldered terminal connecters on. It was a really easy solder and the flux I recently got REALLY helps soldering.

-I also decided to make a harness to hook up the fan and power the stungun from the battery I got. There is one problem....

Try to guess what's wrong with the harness...

Heres a pic

-

Combustion Monkey

- Specialist

- Posts: 153

- Joined: Sun Jan 11, 2009 3:01 pm

Wed Feb 11, 2009 7:19 pm

Not sure about your harness problem. I recommend a flat head screwdriver to pry the case apart on the stungun. Be sure to discharge the capacitor before you try any wiring or you'll get a nice zap. Once I had my stun gun apart it was easy to figure out what i needed to tap into for power and grounds for switches etc.

EDIT: For me, soldering the leads onto the stungun was the fun part. It's tricky to get the terminals hot enough to take solder without melting the wires off the other end of the contact. I suggest clamping a vicegrip or similar tool to the electrode to act as a heatsink.

-

Radiation

- Specialist

- Posts: 183

- Joined: Wed Jul 09, 2008 10:57 am

Wed Feb 11, 2009 8:55 pm

the stunguns case is probably fused together. I used a dremel to cut around the fused edge all the way around the gun. Then you just pull it apart. It's bettter to do it this way because you can take the guts out and wire it however you want. I added a saftey and momentary button as a trigger. Also once you cut the wires to the metal stun prongs you can just crimp on some cables. Beware though isolating high voltage can be tricky, if the leads are too close the spark will jump across near the capicitor and your chamber spark gap will not fire. Also when fiddling around with the stungun do yourself a favor and wears some rubber dish gloves.

-

metallover

- Private 4

- Posts: 95

- Joined: Fri Apr 18, 2008 12:20 pm

Wed Feb 11, 2009 9:29 pm

With the harness, I used a female plug when I should've use a male plug. The battery has a female plug...

I just disabled the alarm on the stun gun and I'm about to solder some wire to go to my electrodes. It will be something like 20awg, which is what goes from the cap to the electrodes. That should work, right?

I'll post some pics when i get done.

Edit- I just found some speaker wire with really thick insulation, I think I'll use that. The insulation is as thick... say a rim on a tire is 16". The length from the edge of the rim to the outside of the tire is another 16". If the rim is the wire and the tire is the insulation, that's an accurate description of the wire.

-

roboman

- Specialist

- Posts: 176

- Joined: Tue Nov 25, 2008 11:18 pm

- Location: Long Beach, CA

Wed Feb 11, 2009 9:41 pm

metallover wrote:A question came up just now. To shoot a tennis ball, 2.5" pvc works. A baseball is 2.5" in diameter. Could I shove it in a 2.5" barrel or would I need to go bigger with a saboe(<-spelling) or wadding?

A baseball would be too big for 2 1/2" PVC. The ID of 2 1/2" PVC is actually 2.469", so you would need to use 3" with a sabot.