High pressure steel piston valved rifle in progress.

Because GGDT is equally capable of giving false supersonic claims. Personally, any velocity GGDT claims will be over 300 m/s, I read as "expect no more than 300 m/s".qwerty wrote:Jhalek why not just use GGDT instead of claiming these "over SOS" figures.

I may find in practise I will get a higher velocity, but I don't go out expecting it.

Does that thing kinda look like a big cat to you?

So, what your telling me is that gasses wil not expand faster than there SOS?Ragnarok wrote: Until you have reliable evidence that you actually achieved that velocity, it is perfectly reasonable for us to argue against your claim, simply based on the reliability of previous claims of that velocity.

The hotter the gas, the faster its SOS... right? or am i wrong?

So, pressure causes gas(Air) to heat up and gain a higher SOS... correct?

The rapid expansion of gas (through a valve ext) cools it, and thus lowers its SOS and therefore the speed at which it can expand?

Meaning that the air in my cannon can only expand as fast as its SOS at any given time... and the only way i would get higer FPS is to raise the gases SOS??

Please correct me if i am wrong.

And thank you for the info. You truly know what your talking about.

Yes. If at any time a flow starts to go supersonic, its own shockwave will instantly slow it back down.jhalek90 wrote:So, what your telling me is that gasses will not expand faster than there SOS?

SOS is the eventual limit on these things.

Correct. This is the main reason why the vast majority of supersonic cannons on this site are hybrids. Not because of the extreme pressure, but because of the extreme heat of the gases.The hotter the gas, the faster its SOS... right? or am i wrong?

The actual increase in speed of sound comes when a gas has a high pressure for its density. This can arise either because of high temperatures, or a lighter gas, like steam, helium or hydrogen (and to a lesser extent, pure nitrogen instead of air).

Compressing air (the more rapidly, the better) causes it to heat up. Pressure alone will not result in a hot gas.So, pressure causes gas(Air) to heat up and gain a higher SOS... correct?

The compressing is typically done by some kind of piston - this can either be solid (as in a springer), or one made out of gas itself (as in supersonic PCPs).

Precisely. It's this cooling that generally means it's very rare to see a pneumatic put out a velocity of more than about Mach 0.95 (in the surrounding air, not the pneumatic's own gas).The rapid expansion of gas (through a valve ext) cools it, and thus lowers its SOS and therefore the speed at which it can expand?

Now, we have seen some supersonic pneumatics, by virtue of extreme pressure and lucky design causing heating of the gas in the dead volume, and actually making the launcher's internal SOS higher than the atmospheric SOS. Still, I stress the importance of pressure on achieving this effect.

As an upper limit. Obviously, if the projectile is (reasonably) airtight, then the gas can't expand faster than the projectile is moving, whatever Mach number that may be.Meaning that the air in my cannon can only expand as fast as its SOS at any given time...

Higher max velocity, as I explain above. Although increasing the gas' speed of sound will help to some extent in a cannon that's shooting subsonic, the real bonuses come by raising the SOS velocity, and the velocity where transonic flow occurs.and the only way i would get higer FPS is to raise the gases SOS??

Transonic is an inefficient area. As the name "transonic" suggests, the flow is fluctuating between where parts of the flow are subsonic and other parts are trying to go supersonic (and as I said at the start, thus creating a shockwave that slows them back down again).

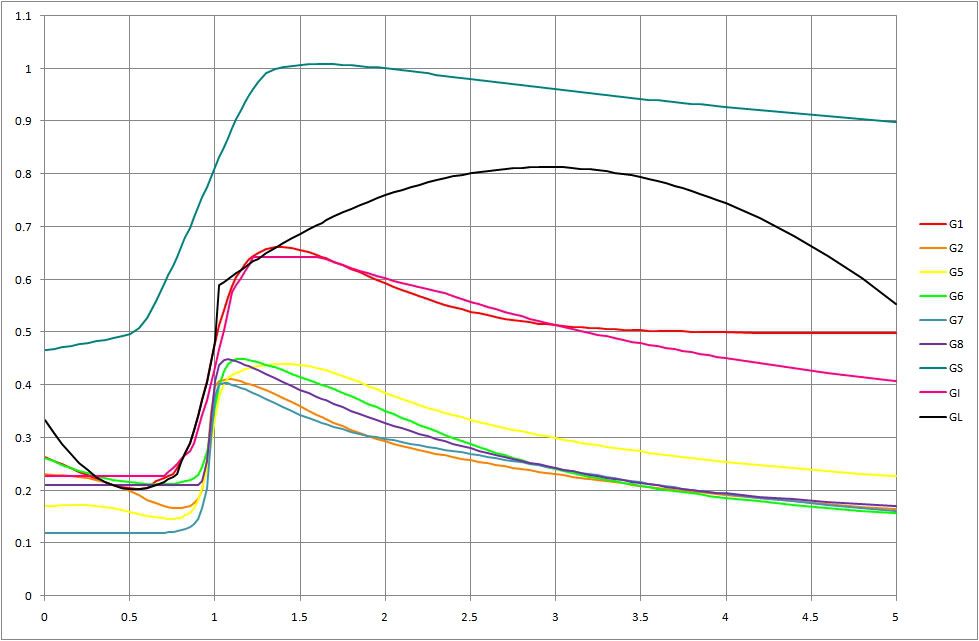

To illustrate the efficiency issue, although it's not quite the same thing, you can see the effects of transonic flow on the drag co-efficient of various shapes on the graph below.

The regime tends to occurs between about Mach 0.8-1.2, but it depends on exact projectile shape (or in the case of launchers, internal design)

As is evident, the transonic regime results in a very large increase in drag coefficient, which actually makes it, per metre of flight, the most wasteful velocity regime for a projectile in terms of percentage of velocity retained. (It's also a region that negatively impacts accuracy because of the sonic shocks causing instability in the projectile.)

Drag coefficient slowly recovers past the transonic area, but it's still behind subsonic flow.

Similar things happen in launchers, causing lots of losses in the transonic region. So, by being able to bring up the transonic velocity, you can yield notably improved performance in the 900-1100 fps range. By being able to bring up the SOS, you can potentially get past the sound barrier in the surrounding air.

Still, I remind you, it's not called the sound barrier because it's easy to beat...

Does that thing kinda look like a big cat to you?

Alright. thank you for the info.

Now, i am going to google this.... but a PCP gun has an air piston?? how in the world does that work??

TO GOOGLE!!!!!!

So from what i understand.... and air piston is a secondary piston that litterally shoves the air behind the projectile...

So valve piston fires... and that shoves the second "Air piston" behind the expanding air, causing the air to be samwhiched between the air piston and the projectile... compressing the air, thus heating it up, raising hte pressure, and raising its SOS.

Also, i cant find a pcp gun that uses less than 2000psi.... so this seems fairly impractical for use in any homemade gun... not impossible... but impractical.

So ragnarok... am i correct??

Aslo... is it possible that i am reaching the max velocity for the air in my valve at its current Sos... i guess my question is... is it possible that the air in my valve is moving near its own sos?

I know i could improve the valve... but as it is... is the air moving as fast as its own sos?? or close to it maybe ??

Now, i am going to google this.... but a PCP gun has an air piston?? how in the world does that work??

TO GOOGLE!!!!!!

So from what i understand.... and air piston is a secondary piston that litterally shoves the air behind the projectile...

So valve piston fires... and that shoves the second "Air piston" behind the expanding air, causing the air to be samwhiched between the air piston and the projectile... compressing the air, thus heating it up, raising hte pressure, and raising its SOS.

Also, i cant find a pcp gun that uses less than 2000psi.... so this seems fairly impractical for use in any homemade gun... not impossible... but impractical.

So ragnarok... am i correct??

Aslo... is it possible that i am reaching the max velocity for the air in my valve at its current Sos... i guess my question is... is it possible that the air in my valve is moving near its own sos?

I know i could improve the valve... but as it is... is the air moving as fast as its own sos?? or close to it maybe ??

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

SSSSssshhh.. You are giving away my plans to go supersonic with my current build.jhalek90 wrote:Alright. thank you for the info.

Now, i am going to google this.... but a PCP gun has an air piston?? how in the world does that work??

TO GOOGLE!!!!!!

So from what i understand.... and air piston is a secondary piston that litterally shoves the air behind the projectile...

So valve piston fires... and that shoves the second "Air piston" behind the expanding air, causing the air to be samwhiched between the air piston and the projectile... compressing the air, thus heating it up, raising hte pressure, and raising its SOS.

Also, i cant find a pcp gun that uses less than 2000psi.... so this seems fairly impractical for use in any homemade gun... not impossible... but impractical.

So ragnarok... am i correct??

Aslo... is it possible that i am reaching the max velocity for the air in my valve at its current Sos... i guess my question is... is it possible that the air in my valve is moving near its own sos?

I know i could improve the valve... but as it is... is the air moving as fast as its own sos?? or close to it maybe ??

- jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

- Contact:

No, not to me from the way his post is worded.jmadden91 wrote:Lol obviously

@Jhalek90: Nice gun mate congrats

From Ragnarok's answer, I can tell what he ment to say.

No, when I say "air piston", I mean it rather literally.jhalek90 wrote:...but a PCP gun has an air piston?? How in the world does that work??

The air coming from the main valve acts as a piston, compressing (and heating) the gas ahead of it in the dead volume.

There's a laboratory device known as a "shock tube" that tends to work in the same way, using air itself as a piston.

I couldn't tell you, I don't know the specifics of your launcher well enough....is it possible that the air in my valve is moving near its own sos?

The actual speed gases move in your launcher will be dependent on the velocity of the projectile and the internal SOS.

Does that thing kinda look like a big cat to you?

- Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

Your valve ( and so far all that I have seen or made myself)So ragnarok... am i correct??

Aslo... is it possible that i am reaching the max velocity for the air in my valve at its current Sos... i guess my question is... is it possible that the air in my valve is moving near its own sos?

Does not allow 100% flow.

At best, even if the piston seals the barrel directly, only about 90 % flow can be reached, due to turbulation around the entry of the barrel.

If it would have a cone, to allow more air to smoothly transfer into the barrel, it would be more likely to reachs the limits.

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Okay... cone like velocity stack?

as is... have a slow chamfer from the port into the barrel?

I was thinking about filing the port all the way to the barrel with weld, and then using a chamfered drill bit to make a velocity stack... how much of an improvement could i expect from something like that??

Edit: i found a new cool looking sealing face... a chamfered neoprene washer... its abot 1/8 in thick at the base... and about 1/4 in thick in the center... with a flat side... is very stiff neoprene

here is a photo.

as is... have a slow chamfer from the port into the barrel?

I was thinking about filing the port all the way to the barrel with weld, and then using a chamfered drill bit to make a velocity stack... how much of an improvement could i expect from something like that??

Edit: i found a new cool looking sealing face... a chamfered neoprene washer... its abot 1/8 in thick at the base... and about 1/4 in thick in the center... with a flat side... is very stiff neoprene

here is a photo.

This will offer an improvement in launcher performance (from the simple view that flow through the valve will improve).jhalek90 wrote:Okay... cone like velocity stack? as is... have a slow chamfer from the port into the barrel?

That doesn't (necessarily) mean that you'll get near launcher SOS with the projectile.

Myself, I mean to try and experiment with near SOS performance using 3vo (when it gets finished, of course).

Hopefully, the data from what I've got planned will cast some more light on the area and enable me to improve my simulations of near Mach velocities.

(Although I intend for 3vo to be a typically subsonic launcher, I'm intending on doing some shots with hydrogen, for various reasons.)

Does that thing kinda look like a big cat to you?

I cant wait to see it.

So, now i have another problem. MY schrader valve keeps blowing out... ive been through 3 in the last 2 days.

It seems to only blow after the valve is opened at over 300 psi.

i mean... it holds 300 psi fine... but when i dump the air it destroys the schrader valve... any suggestions??

So, now i have another problem. MY schrader valve keeps blowing out... ive been through 3 in the last 2 days.

It seems to only blow after the valve is opened at over 300 psi.

i mean... it holds 300 psi fine... but when i dump the air it destroys the schrader valve... any suggestions??

Update:

Got a quick disconnect... works good.... rebuilt the piston... seals better... proabbly like... 99%

pressure tested to 400 psi.. F**King LOUD!!!!!!! i cant even describe.

Ragnarok:

this helped me understand alot of what you were talking about.

Got a quick disconnect... works good.... rebuilt the piston... seals better... proabbly like... 99%

pressure tested to 400 psi.. F**King LOUD!!!!!!! i cant even describe.

Ragnarok:

this helped me understand alot of what you were talking about.