HPA airsoft BBMG w/detent seal

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 344 times

As soon as I can define what I want to achieve, I will ;P

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Gun Freak

- Lieutenant 5

- Posts: 4971

- Joined: Mon Jan 25, 2010 4:38 pm

- Location: Florida

- Been thanked: 8 times

I think the bolt makes it adjustable.

OG Anti-Hybrid

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 344 times

The original idea for this was as a single shot launcher where the chamber would be pressurised with the BB held in the seal by the bolt, and you'd unscrew the bolt to fire. In this context being used as a BBMG, the bolt doesn't really do anything, it's the seal that provides the "detent" element.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 344 times

This incorporated with the seal will give you adjustable release pressure and if placed at the top of the barrel, hopup

hectmarr wrote:You have to make many weapons, because this field is long and short life

what about a screw that pushed directly onto the top of the rubber tube? that would cause the seal to push harder on the top of the bb, and give it backspin, while eliminating potential worries with sealing the bolt because everything is still isolated from the barrel.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 344 times

Faith No More said it best, someone's got to do itlozz08 wrote:having you around has probably saved me a couple of years of fiddling around. It's good because we should advances as a spud civilisation and not repeat the mistakes of the previous spud generation

What would concern me is the seal getting unevenly squashed, but technically it should work and I believe was also suggested elsewhere, as well as Jimmy's idea to use air pressure outside a flexible seal as a "detent", it's in the adjustable ROF thread. You'd need to ensure the seal can accessed for maintenance though.what about a screw that pushed directly onto the top of the rubber tube? that would cause the seal to push harder on the top of the bb, and give it backspin, while eliminating potential worries with sealing the bolt because everything is still isolated from the barrel.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

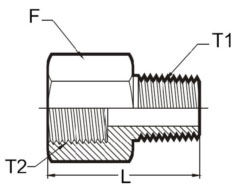

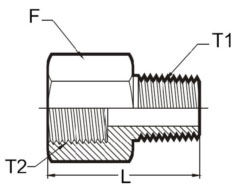

It an be achieved with a rubber washer/o-ring sandwiched between two fittingsadjustable ROF

Children are the future

unless we stop them now

unless we stop them now

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 344 times

As you had done here, but he wants hop-up as well.POLAND_SPUD wrote:It an be achieved with a rubber washer/o-ring sandwiched between two fittings

hectmarr wrote:You have to make many weapons, because this field is long and short life

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

yeah but I think it wouldn't be that difficult to build a hop-up using the same method... the added advantage is taht you can adjust rof and hop-up independently...but he wants hop-up as well

lol I narrowly avoided another posting fail

I've used such home-made compression fittings in quite a lot of applications and it works surprisingly well... it's both on the fridge compressor and it holds the barrel in place on the semiauto MKIII

This is a very useful method of joining metal parts/tubes & fittings that can be undone quickly with a pipe wrench but holds well (both in terms of pressure and mechanically)

Children are the future

unless we stop them now

unless we stop them now

my problem is I'm using a 1/4 inch tee already where the bottom of the tee is an o-ring seal for a removable spring fed mag (I'm going for a realistic kind of gun here) The barrel screws in to one side of the tee, the other side is the air inlet. I need to incorporate the seal into the screw-in barrel.

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

I sandwiched the rubber washer between two 1/2" male-to-female adapter (or whatever you call this part)

So it's not that you need another T

So it's not that you need another T

Children are the future

unless we stop them now

unless we stop them now