I started work on the spark strip. I am using this random plastic rod I found. For the conacts I am using wire that would normally go to outlets and other home wiring. I sharpened the ends of the wire to get a better spark. At the ends of the spark strip the wire is soldered to two bolts which will hold the spark strip in place as well as transfer the juice.

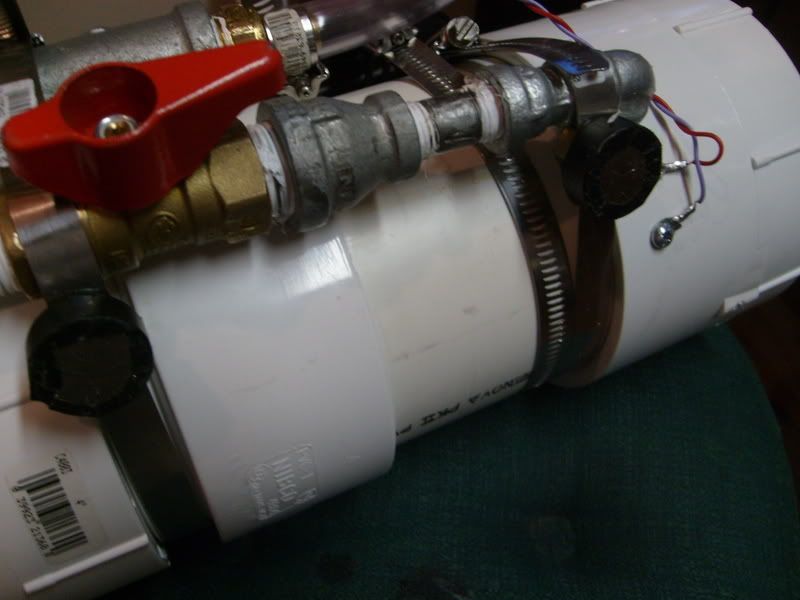

I plan on putting the spark strip right in the middle of the chamber, and I have pretty much ruled out a coaxial. I even got some fittings to make an over/under cannon. If you have any thoughts on that please share them. I'll be able to switch back and fourth because it all screws on.

Here's some pics of my progress-

[OLD meter]