@ MR dew. I had some difficulty with the washer handle. It started leaking and I was pissed because it is brand new. I took it apart, and found some teflon tape blocking the seals (my bad

). It works great now.

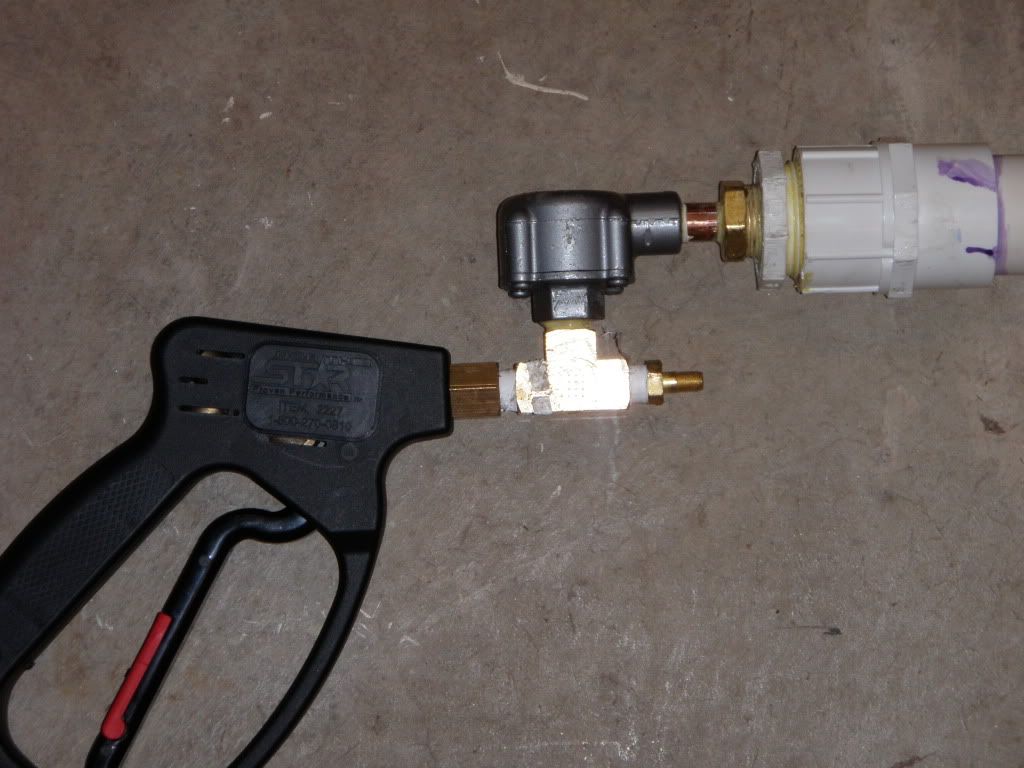

when i was inside it, I noticed something interesting. The washer valve it built almost the same as a blow gun valve, but beefier and it can be used in both directions. (please don't comment on this phrase

)

With the rating being 4000 psi and about 8-12 gpm, i am inclined to use these from now on. This one cost me $19.95 from northern tool (which is really nice because the ones at local stores cost $55 +). It took over a week and a half for shipping though.

Anyway, I built this gun to have a piston valve cannon under my belt before i started my next. I wanted to make a large GB coaxial. 4inch chamber and 1 1/2 inch sdr 21 barrel. GGDT predicts over 450 FPS at 80 psi.

In the mean time, i received my order from mcmaster, but i decided not to install the 3/4 inch QEV because it would be WAAY overkill.

Finally, I've been promoting this idea for more compact launcher for ever! You can go one better and use syringes and piping instead of the copper tube and and make it a hydraulic system

I really like bullpup designs. The cannon that got me started was really awsome. It was a QEV cannon, all copper and had a white handle. It won some contest on one of the European forums. I cant remember who made it, but thank you whoever you are.

EDIT---I found it, by a chance of luck. It was Hotwired's copperhead prime. God I love that gun...

As cool as hydraulics sound, its a little complicated. I'd rather make a push button valve similar to MRR's and place it into a handle.

"I'm spending time without a gender for tax reasons. It's great if I get hit in the groin, but a total nightmare in the bathroom."

-Rag

Obsequium parit amicos; veritas parit odium.

-Cicero