hey no bumping, a day hasn't even passed by yet,

hey DR wana see a trick for conversion, you might know it, go on google and type "6 bar to psi" it works for most conversions

I like your design is it based on

anton's auto ? the part about having a popet hammer valve and piston dedicated to cycling, it's a more streamlined design I like it, oooh and the air comes from tanks in the mags, this designs in great your awesome, now only if you can pull it off

I'm afraid we can't mathematically find you an answer, there's too many variables, the seal around the piston isn't perfect, the friction varies, we don't know how much air is going to come out of the valve and how fast. so I'm going to have to bs the most of my advice without first hand experience,

NGGAAAHHH I am IKM3T BS GUESSTIMATING EVALUATOR 9001

engage bs geustimations

looking at working examples...

comparing surface area's of pistons...

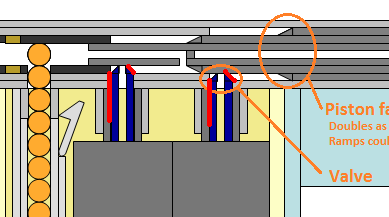

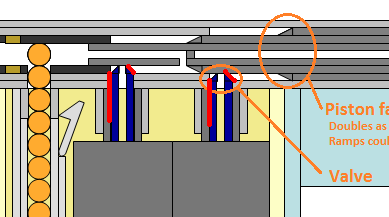

surfaces areas seam sufficient for operation, design has benifet of additional surface area in the piston near the primary firing valve

comparing valves...

!!!

anton's auto has valves along the same axis of movement as pistons, you design translates movement of pistons by angled sliding planes

!!!!

SLIDING PLANES NGAAAH.. danger danger tsukitten the sliding planes contain large amounts of friction that will very likely make this design not operational

!! danger danger as valve is pushed forward it is pushed into the wall of the it is housed in generating even more friction....

generating diagram...

diagram contains areas of particularly high friction in red, anton's prototype contains virtually no friction in the traversing of movement towards opening the popet,

to fix this please redesign the poppet to open when "tilted" or "toggled" rather than restricted linear movement...

proceeding with comparison...

moving bolt/hammer is smaller and streamlined, probably lighter, may benefit from additional mass,

proceeding with comparison... ammo loading part of bolt is opened very far in locked position, extend it so it's just enough for the ammo to feed in the locked open position, this way the bolt ammo bolt is closed for the majority of the stroke so it's less likely to open prematurely

comparison complete

IKM3T BS GUESSTIMATING EVALUATOR 9001 is shutting down