The Offcial Machinist Thread: Revised 01/04/2014

-

evanmcorleytv

- Specialist 3

- Posts: 350

- Joined: Sat Jun 19, 2010 3:44 pm

- Location: Tuscaloosa, AL

Hey everyone, soon, I will need a loading system made.. I will provide the aluminum.. And I will provide a diagram of the loading system.. I will also need a tiny modification to a pneumatic cylinder.. I can also ship, I just need relatively cheap machining.. I will also allow you to make molds of the loading system as well.. you can even sell them.. as long as you give me credit.. PLEASE RESPOND!! I am in Alabama.. again, I will ship the raw materials if needed!!

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Some drawings would give a much better idea of what it is you want to see who might be able to assist.evanmcorleytv wrote:PLEASE RESPOND

... because it's too big, or too small?MrCrowley wrote:Judging by the drill bit size, he's stopped making 'toys' for only his girlfriends...

The world is my <s>oyster</s> bearded clam

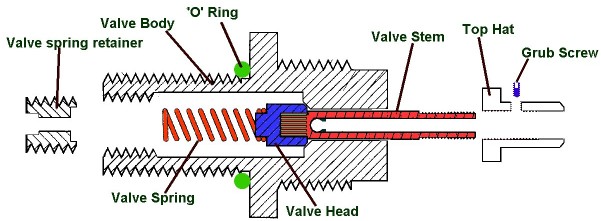

Actually a valve body for a stealth/talon style inline hammer valve.Miniature mortar or a mountain howitzer.

Here it is hot off the lathe next to the drawing jake provided, clearly he's better with a grinder than with a pencil

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

- jakethebeast

- Corporal 5

- Posts: 945

- Joined: Sat Jul 03, 2010 4:20 pm

- Location: Jakes cave

Wow JSR,awesome work!

Est Sularus Oth Mithas

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Cheers, will be on its way to you some time next week  wrap up that blade in the meantime

wrap up that blade in the meantime

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jakethebeast

- Corporal 5

- Posts: 945

- Joined: Sat Jul 03, 2010 4:20 pm

- Location: Jakes cave

yeah, second heat treatment, new tempering and some buffing and its ready to be launched with air powah

Est Sularus Oth Mithas

-

evanmcorleytv

- Specialist 3

- Posts: 350

- Joined: Sat Jun 19, 2010 3:44 pm

- Location: Tuscaloosa, AL

Will do!!jackssmirkingrevenge wrote:evanmcorleytv wrote:PLEASE RESPONDjackssmirkingrevenge wrote:Some drawings would give a much better idea of what it is you want to see who might be able to assist.

- Labtecpower

- Sergeant 3

- Posts: 1297

- Joined: Sat Feb 20, 2010 6:38 am

- Location: Pyongyang

- Has thanked: 5 times

- Been thanked: 13 times

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

To confuse people?Labtecpower wrote:I have no idea what the purpose of this thing is....

Looks good though, nice.

Cheers, it was a pleasure to make these parts and good practice too, and really this is the sort of collaboration I am hoping will grow on spudfiles - it felt much better to do this for a lovely blade than for money, this way both members end up with unique parts in hand.JSR...Nice work man. Its good to see this thread serving a real purpose.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Labtecpower

- Sergeant 3

- Posts: 1297

- Joined: Sat Feb 20, 2010 6:38 am

- Location: Pyongyang

- Has thanked: 5 times

- Been thanked: 13 times

To confuse people?

Like i'm going to drop a lot of patient working somewhere in the US

Why do allmost all of these turning projects look so nice and shiny?

-

motorfixer1

- Private 4

- Posts: 91

- Joined: Wed Jul 07, 2010 5:28 pm

I think your answer is emery paper or scotchbrite!Why do allmost all of these turning projects look so nice and shiny?

- jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

- Contact:

Or sharp cutters and proper cutting speed...motorfixer1 wrote:I think your answer is emery paper or scotchbrite!Why do allmost all of these turning projects look so nice and shiny?