They both have a 1" Barrel surrounded by a 2" chamber.

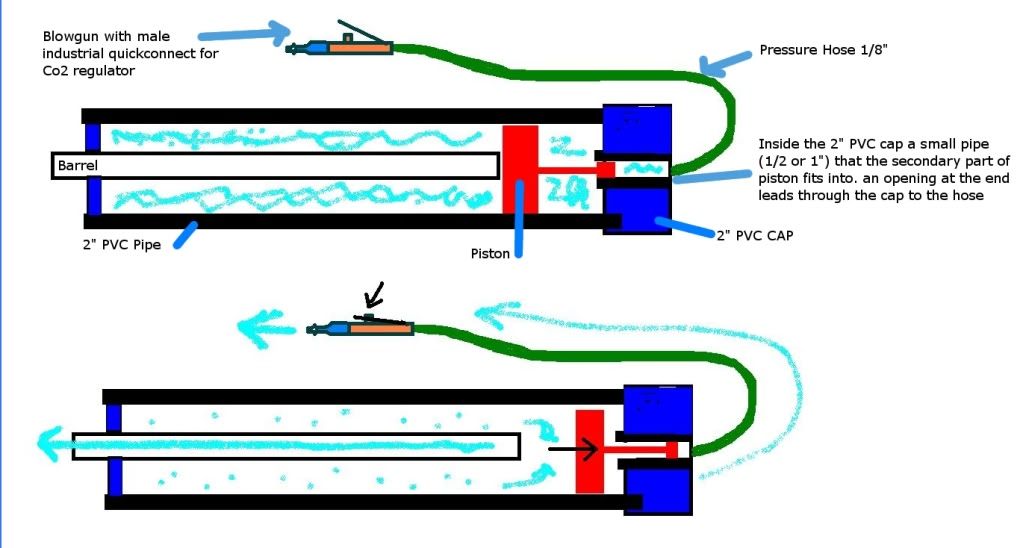

The first, and the preferred design uses a piston made from a 1 1/4" PVC cap with a rubber seal for the barrel that is connected to a smaller piston by a screw. The smaller piston fits into a smaller pipe that goes right up to the back of the 2" PVC cap. Then it will lead into a pressurized hose that leads to a blowgun. The blowgun is the exhaust valve/ trigger.

This design is more complicated but is more compact and would allow me to fin the whole setup into a 3" PVC Pipe for extra protection, since I am planning to use it for airsoft.

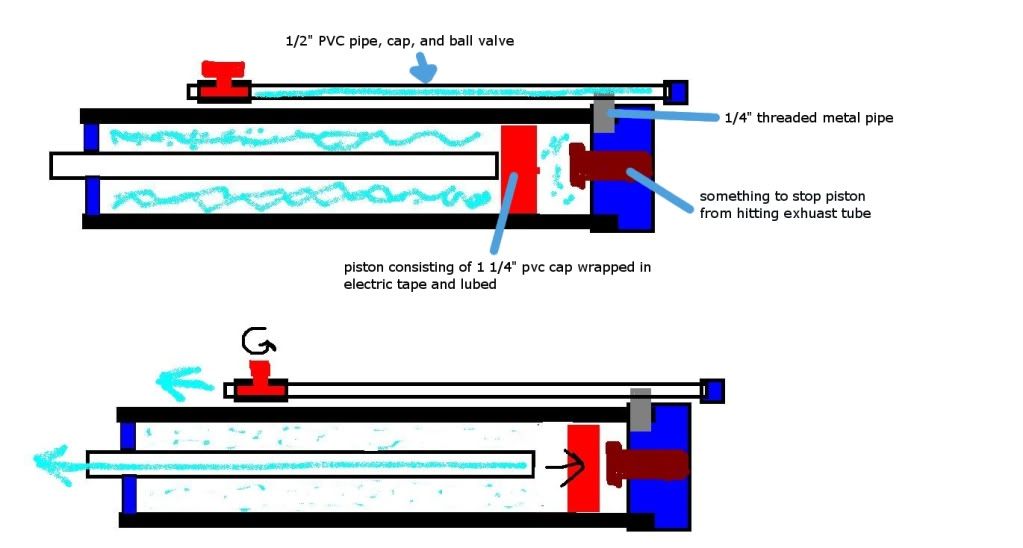

The second is design uses just the 1 1/4" PVC cap as a piston and uses a 1/2" PVC pipe and Ball valve to vent.

Would the first design work? If not is there anything I could change to make it work?

Also is the 2" chamber and 1" barrel going to give me very much power at 70-90 PSI?

Thanks