I understand all of it except for one part.

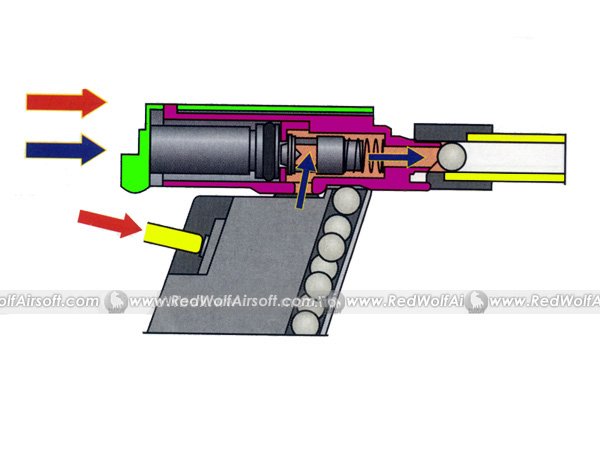

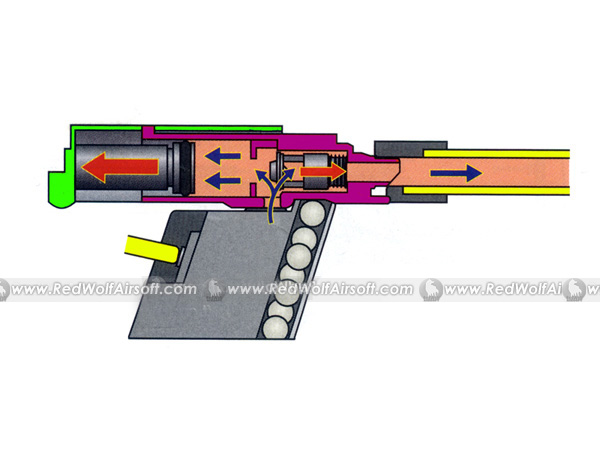

They claim that the floating valve, the silver part that moves forward when firing, doesn't move until the bb has left the barrel. How can that be? Apparently somehow the pressure is keeping it from moving. But how?

In my head, the whole mechanism is similar to a QEV valve (there is no pilot valve and stuff), with the barrel attached to the pilot port. The valve is not pressurized, pressured gas rushes in from the fill port when the hammer valve is hit, some gas escape through the pilot port into the barrel, creating a pressure difference hence "wind" that pushes the piston forward, closing the pilot port (barrel) and directing the rest of the gas to the bolt carrier.

I don't see how pressure can keep the floating valve back when the bb is still moving down the barrel. Isn't there already a pressure difference as the bb is moving, and thus the floating valve should close?