I came across this video of a piston valve air cannon bursting.

All of the pipe appear to be schedule 40, they even said it only had 90 PSI in it, which is very concerning.

Someone please shed some light on what might of happened. I was about to build a similar sized cannon with a 3'' barrel.

Concerning video of a Piston Valve Cannon bursting

- mrfoo

- Specialist 2

- Posts: 275

- Joined: Wed Apr 29, 2015 11:05 am

- Has thanked: 86 times

- Been thanked: 90 times

There's a lot of mass in a 3" piston, and PVC is fragile. The break at the barrel end was clean and exactly at the stress riser where the reducer meets the valve body, looks like shock fracture rather than pressure rupture. Lesson to learn - don't do that.

At 2:00 or so, he says "That's not funny. It's a lot of money" rather than "fuck me, that could have taken my hands off". He has not learned.

In passing, when using should've, could've, would've, might've and so on, although you might pronounce the "ve" similarly to "of", it's a contraction of "have". As in "what might have happened". Personal bugbear of mine.

At 2:00 or so, he says "That's not funny. It's a lot of money" rather than "fuck me, that could have taken my hands off". He has not learned.

In passing, when using should've, could've, would've, might've and so on, although you might pronounce the "ve" similarly to "of", it's a contraction of "have". As in "what might have happened". Personal bugbear of mine.

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 581 times

- Been thanked: 347 times

Agreed, all the force is on that PVC tee. If you are making an over/under piston cannon out of PVC, the barrel ought to be supported. Even just a piece of wood between the two and a bunch of zip ties will limit the movement and therefore the stress.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- mrfoo

- Specialist 2

- Posts: 275

- Joined: Wed Apr 29, 2015 11:05 am

- Has thanked: 86 times

- Been thanked: 90 times

No, I think it would have been better to not use PVC.

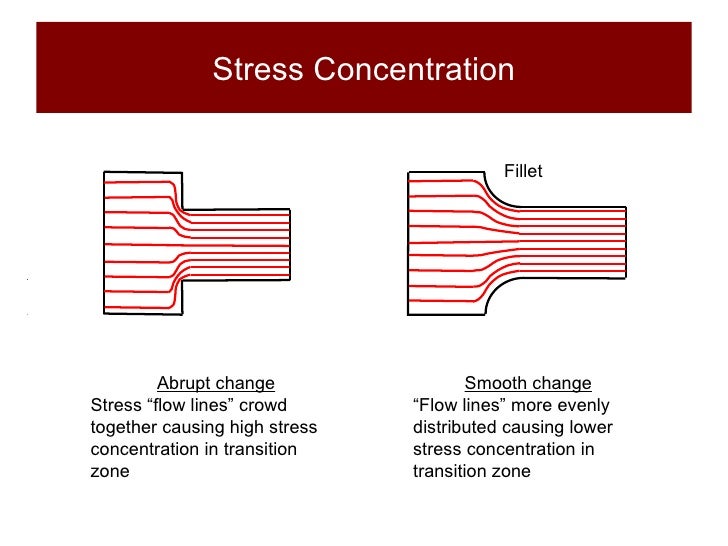

My guess as to what's happening is that the piston shoots backwards as intended, the pressure behind it perhaps blows off the ball valve (that could also have been shock related or just down to dropping the broken cannon), the piston then impacts the back of the chamber, and creates a shock wave that then runs back through the PVC and concentrates at a shock riser that has also, coincidentally, had its structural integrity compromised by the use of solvents. The fact the barrel was flapping in the breeze probably didn't help either, per JSR's comment.

The problem could perhaps be alleviated by use of a radiused (not necessarily funnelled) joint, but the solvent issue still stands, as does the shock wave. Perhaps physical damping on the back of the piston, too. But ultimately, you're still talking about shock loadings on a fragile material that's not designed to handle it.

IMO, and others may well disagree - "I've made ... PVC cannons and they've never failed" - , PVC *will* fail in this usage, it's not a question of "if" but "when". The bigger the cannon, the sooner it will happen. Sure, it's easy to get hold of, it's lightweight and relatively cheap, but fingers and eyes aren't replaceable.

- Moonbogg

- Staff Sergeant 3

- Posts: 1737

- Joined: Mon Oct 13, 2008 10:20 pm

- Location: SoCal

- Has thanked: 166 times

- Been thanked: 102 times

I agree with the others about the stress on the joint where the barrel meets the chamber. An unsupported barrel seems to be one of the more common causes of failure. I wish I could offer some advice that would guarantee a PCV cannon won't break, but such advice doesn't exist for any cannon I'm afraid. Even in the firearms industry where people have the benefit of hundreds of years of experience, billions of dollars of investment, world-class engineering, and millions of examples to learn from, guns still explode. It doesn't happen often, but I've seen videos of people hunting and their rifle barrel split into 3 pieces, just like in the friggin cartoons.

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 581 times

- Been thanked: 347 times

In other news, it seems the swear filter has not made it to the new spudfiles!

You can say fuck, shit, bitch, whatever you want!

Cock, balls!

hectmarr wrote:You have to make many weapons, because this field is long and short life

- mrfoo

- Specialist 2

- Posts: 275

- Joined: Wed Apr 29, 2015 11:05 am

- Has thanked: 86 times

- Been thanked: 90 times

Don't make me bring out Bob the Angry Flower.

It's a 2" cannon, as opposed to the original's 3". For the same piston construction, the piston will have a mass that is at least 4/9 (2^2 / 3^2) less than that of the larger cannon. The force applied to it, for an equal pressure, will also be 4/9 of that of the larger cannon. Thus its energy will be about 16/81, or about one fifth that of the larger cannon. It has a better chance of surviving the first shot.

- Moonbogg

- Staff Sergeant 3

- Posts: 1737

- Joined: Mon Oct 13, 2008 10:20 pm

- Location: SoCal

- Has thanked: 166 times

- Been thanked: 102 times

Also, if you decide to make a combustion cannon, there is a particular fuel that you should avoid at all costs. Almost every time a combustion cannon explodes in someone's hands, it's because they used propain instead of propane.

- farcticox1

- Sergeant

- Posts: 1085

- Joined: Sun Mar 31, 2013 12:37 pm

- Has thanked: 69 times

- Been thanked: 102 times

PVC is not rated for gas pressure so no surprise, some of the older water lines in the plant I work in have failed with 40psi of water in them, and that's what it is designed for, usually on the inside of 90 bends, water hammer.